Injection Mold Cleaning

All You Need To Know About Injection Mold Cleaning

It is a common belief that the task of injection mold cleaning is a very challenging and dangerous one filled with many complexities; however, this is a misconception for if the cleaning process is based on a particular strategy there is little chance of any problems or failures. In fact, if the cleaner follows a clear cleaning strategy mold cleaning can be relatively simple. In order to complete effective injection mold cleaning it is imperative that the mold be maintained throughout the procedure. This article will provide useful information on how to complete a successful injection mold cleaning.

What does a mold actually do?

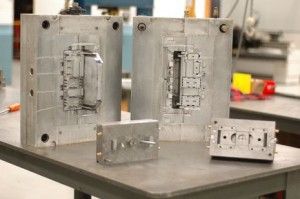

A mold is an item that is able to work under extreme amounts of pressure, as create by humid settings. The mold operates by manipulating plastic to prepare particular parts through opening, closing, rotations, heating and cooling. Molds are developed to work approximately 5,000 hours per year and produce products that are both dimensionally and aesthetically attractive. The form of plastic part is dependent entirely on the mold being used.

How is a mold cleaned?

To produce high quality and high quantity plastic products it is necessary to have a routine schedule of both uptime and downtime. During the downtime the molds must be properly maintained via effective injection mold cleaning, repairing and refurbishment. Of course, to maintain superior operations it is essential that the molder present a planned maintenance schedule in addition to preventative mold maintenance programs. The preventative programs reduce the potentiality of damage to the machine by rust and corrosion.

What are the different types of injection mold cleaning strategies?

There are various types of injection mold cleaning strategies available with the two most commonly used methods being in-press cleaning and on the bench cleaning. In-press cleaning involves cleaning the mold while it is still fully assembled; as well as fully mounted on the injection mold equipment. This type of cleaning is generally utilized after a specific number of production cycles have been completed as it is a more convenient method for the mold cleaner. Of course, the number of production cycles to be completed before in-press cleaning can occur is specific to the mold manufacturer.

The second cleaning strategy is known as on the bench cleaning. This method is most beneficial if cleaning is being done using solvents more suited to a cold injection mold. Unlike the in-press option, the on the bench cleaning alternative involves scrubbing the mold when it is off the equipment; furthermore, it focuses on removing any rust and resin that are present on the mold’s surface.

When choosing a particular cleaning method it is important to ask specific questions to identify which option is best suited to your needs. Firstly, you must determine the type of resin to be dissolved; you must also consider the cavity surface and the nature of the mold’s core.

Final words on the matter

The act of cleaning a mold can be overwhelming; however, by following the advice above it can be less daunting than originally anticipated.