-

The Vapor Hone 1000 is backed by the industry’s best LIFETIME WARRANTY

-

100% Made in the USA

-

American tech support Mon- Fri

-

Fully welded stainless steel forklift slots to easily move the machine for servicing

-

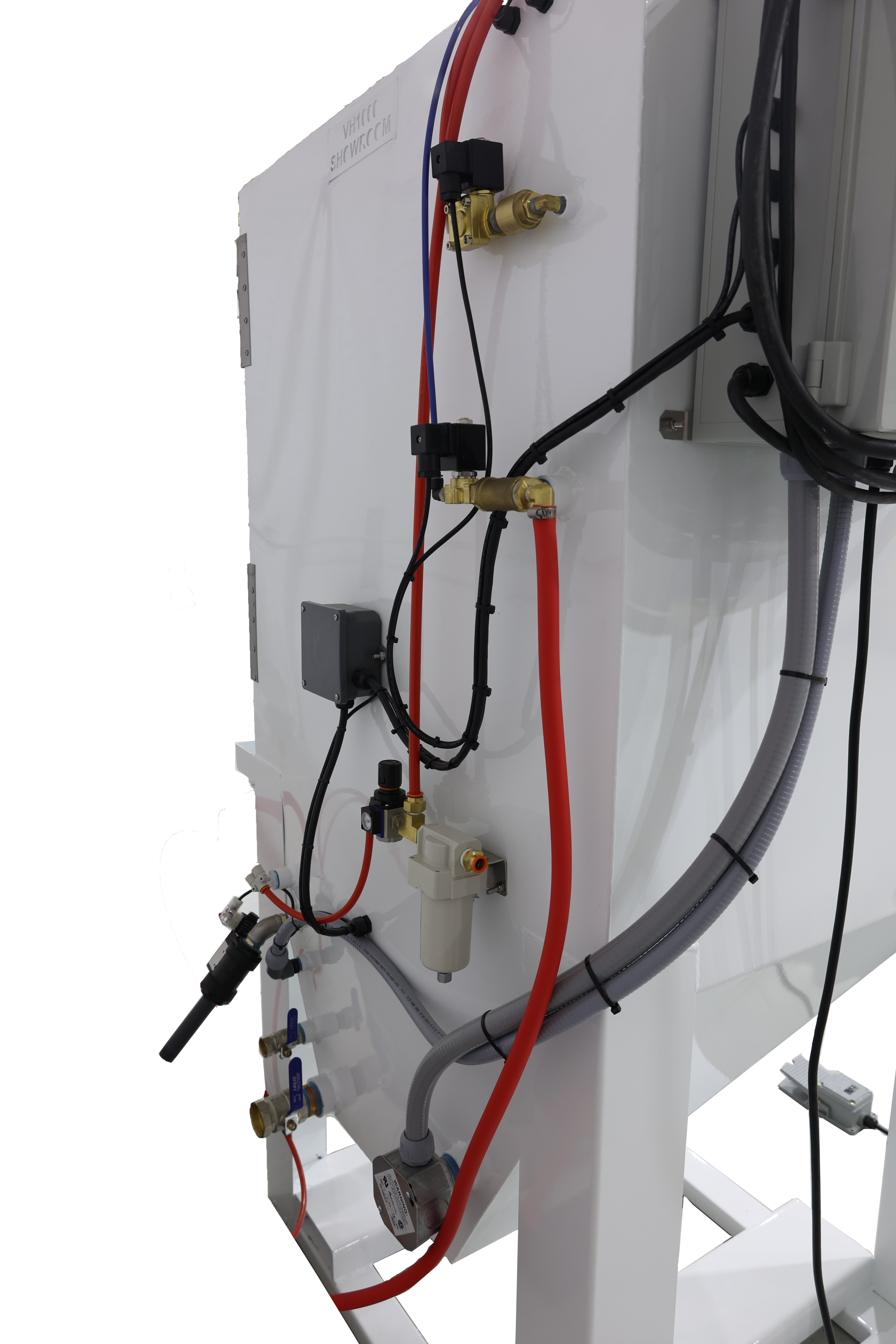

Optional feature of closed loop or open loop

-

Example – closed loop basins will be located underneath machine

-

Automatic overflow valve

-

Comes with a foot pedal that operates blasting gun (this image doesn’t show foot pedal)

-

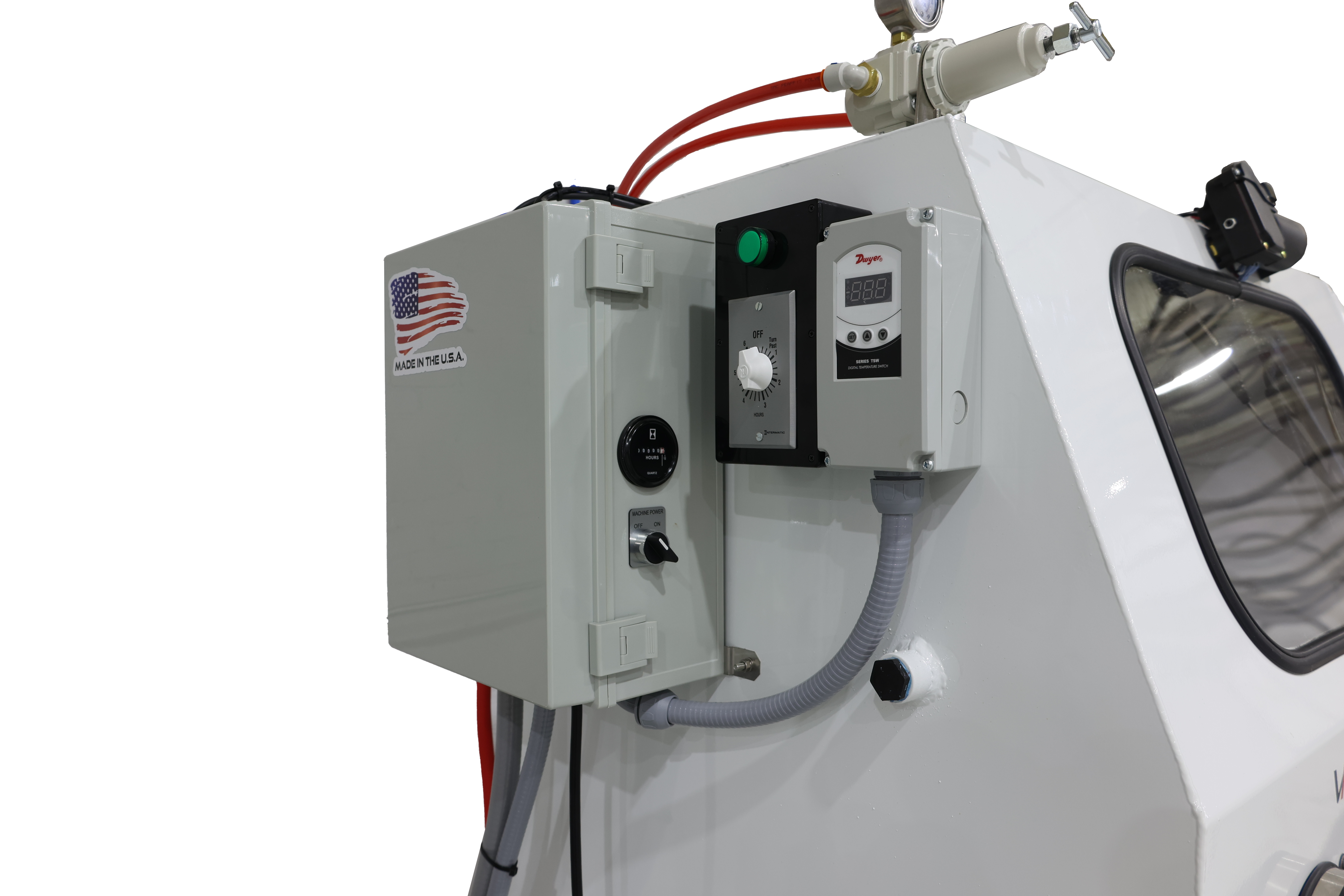

Precision air regulator

-

On and off switch located on the right of the machine

-

The Vapor Hone 1000 is fully factory tested and assembled

-

Machine exterior is painted White

-

Right-hand side load door

-

2x LED light bar for better visibility

-

Internal rinse nozzle

-

Safety door interlock switch

-

All equipment service connections are on the back of the machine

-

The Vapor Hone 1000 is fully factory tested and assembled

-

Industrial machine built to last a lifetime

-

1/2″ NPT air connection is needed

| Internal Working Dimension | 36″ W x 30″ D x 38″ H |

| Power | 110V Single Phase or 220 V |

| Abrasive Amount | 32 lbs. |

| Water Amount | 22.5 Gallons |

| Pump | High Volume Slurry Pump |

| Gun Tips | Boron Carbide Blasting Gun Tips |

| Compressor Specs | 7.5HP or Larger |

| CFM | 20-30 CFM |

| PSI | 60-100 PSI |

| Assembly | No Assembly Required |

Optional Features

220V 3 phase

3K Sump Heater

Closed loop rinsing sedimentation tank

Abrasive density meter

Rubber lined walls for abrasion resistance and noise suppression

Track and car system for loading heavy parts

1,000 lbs. capacity stainless steel turntable

Vapor Hone 1000 is fitted with the optional closed loop filtration system

Unleash Power and Precision with the VH1000: Your Industrial Command Center!

Gear up for unparalleled performance with the VH1000 from Vapor Honing Technologies, engineered for the rugged demands of industrial settings. Constructed from robust stainless steel, this beast stands tall and offers impressive 36″ W x 30″ D x 38″ H internal working dimensions. Every feature that made the VH800 FL exceptional is amplified with the VH1000! The wiper, automatic overflow valve, precision regulator, and air filter are all still present.

But that’s not where it ends. The VH1000 also boasts floor supports, making it the ultimate powerhouse for handling massive parts like engine blocks. Additionally, the closed-loop filtration system is tucked beneath the machine, saving space while amplifying efficiency. The VH100 is not just a machine; it’s a fortress of productivity!

Increasing your operating potential and efficiency today!

To add a heater to your machine, please call 828-202-5563.

Don’t forget your blast media!

For any questions, please call 828-202-5563.

Probably the most practical sized machine for most cleaning or surface finishing applications. I have never seen a product built so tough before this is a rock solid product.

Matthew S,

Florida

Love the wiper setup on this machine. Buy closed loop if you have the extra cash its worth it.

Terry G,

Alabama

- What’s the regular maintenance on vapor blasters as a whole?

- How often do I change media and water?

- Can I mix in something to stop freezing in the winter if I don’t have the unit in a place with heating?

- What abrasives can I run in the vapor hone?

- Does vapor honing take a lot of CFM?

- Really just changing the water and abrasive that’s it. Consumables will last much longer in the wet systems due to the cushioning effect.

- If you use it every other day i would change every month. If its occasional use you might go 2-3 months.

- One of the most frequent questions that I don’t have a good solution for other than draining the machine if you know it will be sitting for more than a week in the col weather. I personally try to minimize mixing any thing other than water and abrasive because it can create bad finishes if it throws out the PH of the slurry.

- Any abrasive that you run in a dry blasting cabinet will run in a vapor hone machine.

- It depends on what you define as a lot any wet cabinet can need 15-45 CFM to operate just depends on what machine model you choose.

If you like to see other machines in action or our before and after results, please visit our YouTube channel and subscribe

Click Below