- The Hydro Blast Max is backed up by the industry’s best LIFETIME WARRANTY

- 100% built in the USA

- American tech support Monday – Friday

- Model is built to last

- Constructed with carbon steel

- Machine exterior is painted Gunmetal Gray

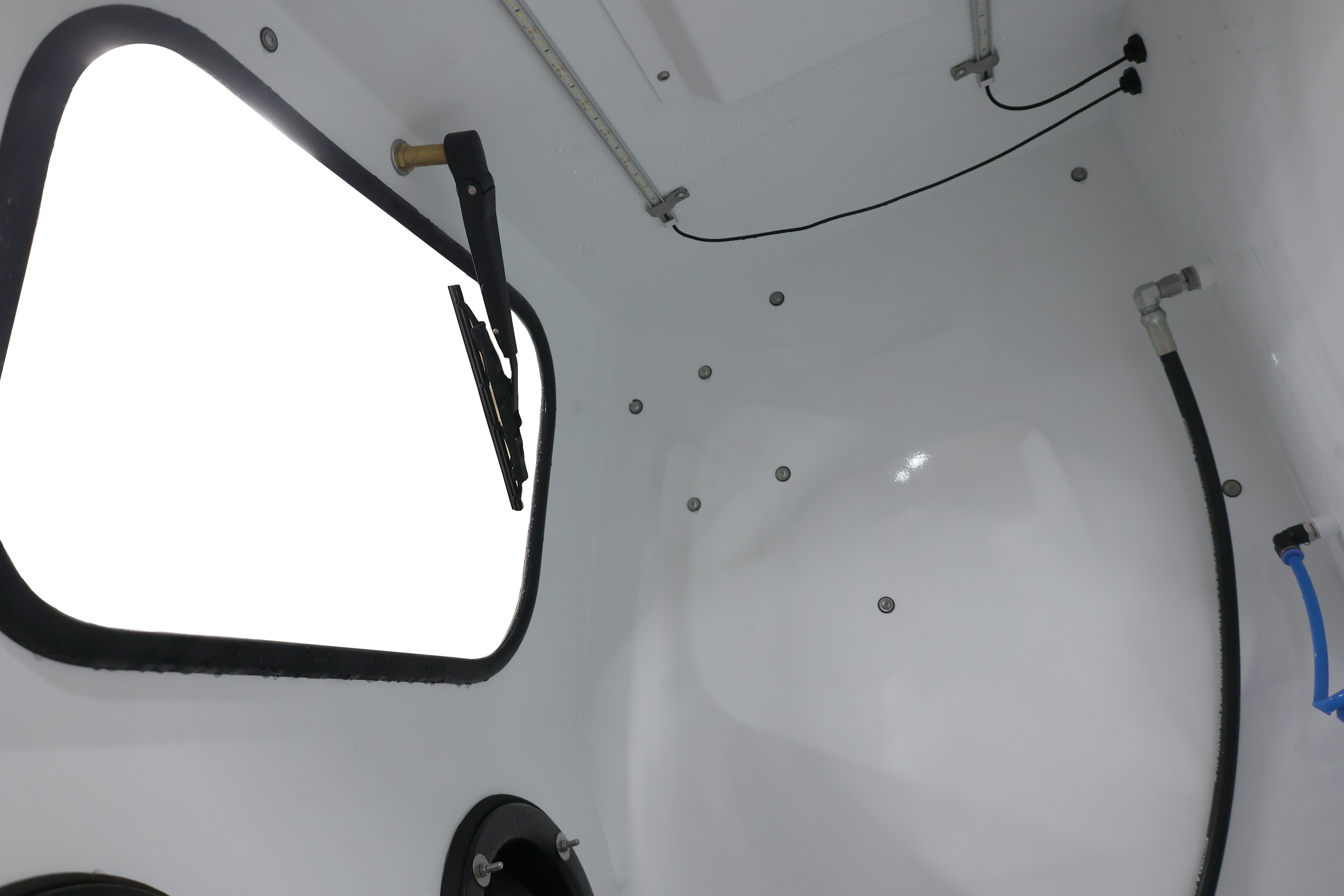

- 2 (2′) LED light bar for better visibility

- Right-hand side load door

- Wiper included

- Foot pedal control

- Upgrade option w/o depreciation

- Oil skimmer

- Dryer hose inside

- The Hydro Blast Max is the ultimate high pressure parts washer, as it easily removes contaminants from parts. Its 4000 working PSI makes certain you can find the correct cleaning pattern for your parts.

- A heater comes standard with the Hydro Blast Max, which aids in the removal of oil, grease, and grime. An oil skimmer is also included with this machine, which removes oil from the surface of the water, keeping clean water supplied to the blast gun.

- The Hydro Blast Max can be used with an aqueous based detergent to aid in grease and grime removal.

| Internal Working Dimensions | 36″ W x 30″ D x 38″ H |

| Power | 220V Single Phase or 480V Three Phase |

| Abrasives Amount | NO ABRASIVE |

| Water Amount | 30 Gallons |

| Pump | High Volume Pressure Pump |

| Compressor | Small Compressor, Powered by Electrical |

| PSI | 4000 PSI at The Gun |

| Assembly | No Assembly Required |

1. What’s the regular maintenance on vapor blasters as a whole?

2. How often do I change media and water?

3. Can I mix in something to stop freezing in the winter if I don’t have the unit in a place with heating?

4. What abrasives can I run in the vapor hone?

5. Does vapor honing take a lot of CFM?

1. Really just changing the water and abrasive that’s it. Consumables will last much longer in the wet systems due to the cushioning effect.

2. If you use it every other day I would change every month. If its occasional use you might go 2-3 months.

3. One of the most frequent questions that I don’t have a good solution for other than draining the machine if you know it will be sitting for more than a week in the cold weather. I personally try to minimize mixing any thing other than water and abrasive because it can create bad finishes if it throws out the PH of the slurry.

4. Any abrasive that you run in a dry blasting cabinet will run in a vapor hone machine.

5. It depends on what you define as a lot any wet cabinet can need 15-45 CFM to operate just depends on what machine model you choose.

If you like to see other machines in action or our before and after results, please visit our YouTube channel and subscribe

Click Below