Our New 5 CFM Air Jet

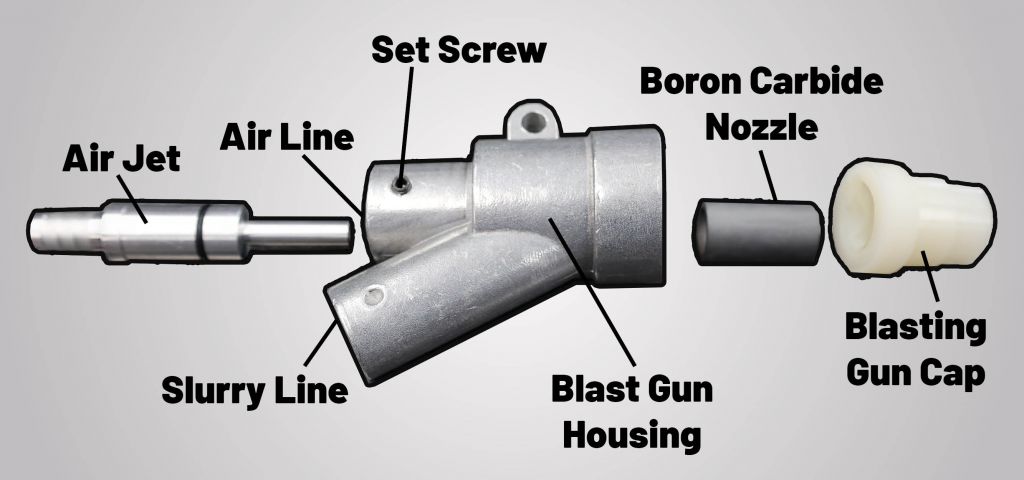

Interested in getting a Vapor Honing machine but don’t have an air compressor that can support the required CFM to run it? Well, we have great news! Here at Vapor Honing Technologies, we are now offering a 5 CFM air jet. In every blast gun, the air jet provides the force that accelerates the slurry. Typically, these jets required 20-30 CFM to operate successfully. Now with the new 5 CFM jet, this barrier will no long stand in the way of operation. You too can run a vapor honing machine with a smaller shop air compressor.

What does CFM Stand for?

CFM stands for cubic feet per minute. It is the measurement of the volume of air that can flow through an opening in one minute. The higher the CFM number means the greater the airflow. Think of this like gallons per minute in relation to a water hose.

Why CFM Matters When Vapor Honing:

Vapor Honing with a compressor that falls short of the necessary CFM (Cubic Feet per Minute) requirements can significantly compromise the effectiveness of the operation. The CFM rating of a compressor is crucial for maintaining a consistent and powerful stream of slurry during wet blasting. When the compressor lacks the required CFM, the delivery of the mixture becomes inadequate, leading to suboptimal results in deburring and surface finishing tasks. Moreover, an insufficient CFM can strain the compressor, causing it to work harder than its capacity, resulting in quicker tank depletion. This not only hampers the overall efficiency of the wet blasting process but can also lead to increased downtime and potential wear and tear on the equipment. It is essential to ensure that the compressor meets or exceeds the recommended CFM specifications to achieve optimal performance and desired outcomes in wet blasting applications. This is also why our air jet’s ability to lower the required CFM is a big deal.

How It Works

The science behind this is quite simple. The smaller opening on the 5 CFM jet creates more back pressure and allows less air to flow. This allows you to blast at higher pressures longer than you would be able to with a standard air jet and an insufficient compressor. Please note that while you can achieve the same results with both jets, the process will take longer with the 5 CFM jet due to less air being present to accelerate the slurry mixture.

How Do You Replace Your Air Jet? Easy, Just Rip It And Stick It!

We are excited to interduce this optional part to our customers to broaden the accessibility of Vapor Honing for all. Also keep your eyes open for future air jets with more variances for even better presession when choosing a part right for your air compressor, and machine.

15 CFM Air Jets Are Here

Want to lower your air consumption, but don’t need something a reduced as the 5 CFM air jet? Now we have the 15 CFM air jet! Get comparable results to the standard air jet at half the CFM usage. This compact jet seamlessly integrates with the standard blast gun and is designed for easy installation.

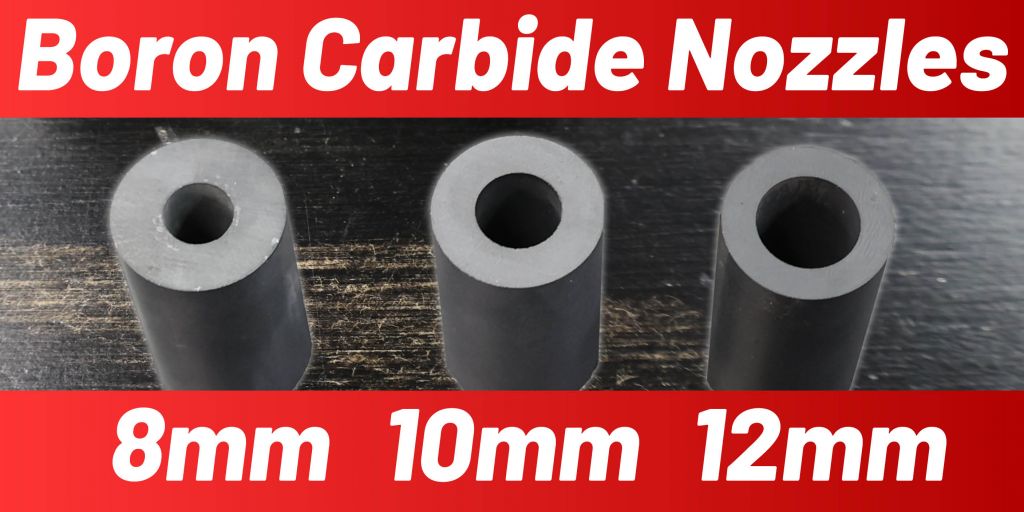

This air jet may lengthen the blasting process, as a lesser volume of air will be propelling the slurry, but the finished results will be the same. We recommend pairing this jet with an 8mm nozzle tip.

Choosing a Nozzle

The nozzle tip size plays a big role in determining the efficiency and effectiveness of the vapor honing process. Smaller nozzle tip sizes provide a more concentrated and focused stream of abrasive. Due to the focused steam the abrasive flows at a higher velocity. Smaller the nozzle also means consuming less air, water, and abrasives. Downside to a smaller nozzle is it can lengthen the overall period of time spent Vapor Honing, making it less efficient. Larger nozzles are much better for efficiency, widening the range you can finish part surfaces. Larger nozzles do benefit from more robust air compressors and will also go through abrasive faster than a smaller nozzle.