Terminology

A

Abrasive(s) –

Is a consumable material that is sand size and smaller, that is used to shape or finish an object’s surface.

Abrasive Blasting –

Is when you shoot pressurized air mixed with dry abrasive or with the combination of pressurized air, abrasive, and water to shape a part or clean the surface. There are many terms used within the industry to describe abrasive blasting such as; sandblasting, grit blasting, wet blasting, dry blasting, or media blasting.

Abrasive Density Meter –

Measures the density of abrasive vs water. On our machine this is automated.

Aerospace Industry –

Dedicated to the research and development of flight-performing vehicles.

Aggressive Media –

Angular-shaped abrasive used in both wet and dry cabinets.

Aluminum Cabinet –

Wet blast cabinet that is built with aluminum sheet metal.

Aluminum Oxide –

A type of abrasive used in both wet and dry blast cabinets. Aluminum oxide is angular shaped and is one of the most aggressive media. It has a MOH scale hardness of 9, which is right below diamond. This abrasive is great for removing paint and or coated surfaces.

Auto Parts Washer –

A 16″W x 16″D x 10″H parts washing cabinet. Uses only water to clean parts, Not compatible with abrasive. This cabinet will wash your parts automatically once you have it set up. Currently Not Available.

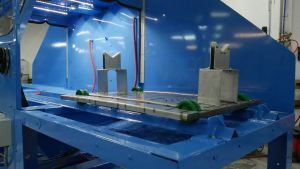

Automated Indexing Station –

A 60″W x 60″D x 48″ H industrial/commercial wet blast cabinet. Fully automated and has a large HMI user interface. To learn more click the name above.

Aqua Blasting –

Is a process that propels pressurized air mixed with dry abrasive and water at a surface to clean or prep for paint. Also known as wet blasting, vapor blasting, hydro blasting, vapour blasting, liquid honing, slurry blasting, and vapor honing.

B

Baking Soda –

A soft consumable material that can be used to clean and cook. This kind of baking soda is in crystalline small powder form.

Base –

Meaning minimal features

Basin –

A rectangle container that holds water for a closed loop wet blast cabinet.

Basin Caster –

A free-flowing wheel attached at the bottom of a basin making it mobile. Caster makes mobility easy.

Bead Blast –

Is when you shoot pressurized air mixed with dry abrasive or with the combination of pressurized air, abrasive, and water to shape a part or clean the surface. There are many terms used within the industry to describe beat blast such as; sandblast, grit blast, wet blast, dry blast, or media blast.

Bench Top Blast Cabinet –

Wet blast cabinets that are made to sit upon a tabletop.

Bench Top Vapor Hone 450 –

A 20″W x 15″D x 28″H stainless steel front load vapor honing machine that sits comfortably on any benchtop. This machine can either be stainless steel, aluminum, or carbon steel. To learn more click the name above.

Bench Top Vapor Hone 650 –

25″W x 25″D x 23″H stainless steel vapor honing machine that sits comfortably on any benchtop. This machine can either be stainless steel, aluminum, or carbon steel. To learn more click the name above.

Blasting Cabinet –

A term that uses compressed air to propel abrasive to clean or shape an object’s surface. Can mean a sandblast cabinet or wet blast cabinet.

C

Carbon Steel Cabinet –

A vapor honing cabinet that is built with carbon steel sheet metal.

Caster –

A free-flowing wheel that is designed to be attached at the bottom of a large object, making mobility easy for a large object.

CFM

CFM stands for cubic feet per minute. It is the measurement of airflow exhausting out and is the most common way to measure airflow. The higher the CFM number means the greater the airflow.

Clean by Flow –

Due to the addition of water, the slurry mixture tends to follow the contour of the part, rather than bouncing off. Additionally, the water lessens the impact of the abrasive on the part, allowing for a less damaging and smoother finish creating blasting process.

Closed Loop System –

A closed loop system does not use an external water source as it recycles the water through its system. Two external sedimentation basins allow the abrasive to settle before it is re-introduced into the system while using the internal rinse. The water used for blasting is stored in the hopper of the machine, and that is where the abrasive and water are mixed.

Crushed Glass –

Is a type of abrasive that is used in both dry and wet blast systems. Crushed glass is angular shaped and is a fairly aggressive media that is great for paint removal and etching. MOHs hardness scale of crushed glass is between 5-6.

D

Drip Tray –

A tray that is located below the door of a wet blasting cabinet. Its purpose is to catch dripping water from the door and route it back into the hopper.

Dry Blasting –

Is a process where compressed air and abrasives are used to treat or shape a surface.

Dry Blast Cabinet –

A workstation that contains the dry blasting process. Also known as a sand blast cabinet.

Dustless Blasting Machine –

A work station that propels pressurized air mixed with dry abrasive and water at a surface to clean or prep for paint. Also known as vapor honing machine/wet blast machine.

E

Econoline 3630 –

A 36″ W x 30″ D x 38″ H stainless steel or carbon steel, side load vapor honing cabinet. To learn more click the name above.

F

Fully Loaded (FL) –

Meaning maximum/best features for a type of wet blast cabinet.

Foot Pedal Control –

Simply an on/off pedal switched by the foot.

Footprint –

The overall dimension of our vapor blasting machine.

Front Load –

An accessing point, where you load and unload parts through the front of a vapor honing machine.

G

Garnet –

A type of abrasive used in both dry and wet blasting. Garnet has an angular shape and has a hardness of 8 MOH. Great for removing paints fast and etching can be done with this media.

Gladiator –

A 36″W x 30″D x 30″H stainless steel, front load automated vapor honing cabinet. Graded for commercial use. Only available in stainless steel. To learn more click the name above.

Glass Bead –

A type of abrasive used in both dry and wet blasting. Glass bead is spherical shape and has a hardness of 5.5 MOH. Great for removing contaminants without damaging the surface.

Guillotine Doors –

Pneumatic sliding door that opens and closes in a linear motion.

H

High Density Polyethylene (HDPE) –

A thermoplastic polymer made from petroleum. HDPE is a type of plastic that is lightweight and rugged. It is also high impact resistance. HDPE applies to these types of machines; Weekend Warrior, VH800, VH1200, Micro Vapor Hone, and Hydro Blast.

Hopper –

The taper bottom section of a cabinet, where the abrasive and water are pumped from.

Hydro Blast –

A 33″W x 30″D x 28″H side load, HDPE plastic parts washer. Uses only water to clean parts, Not compatible with abrasive. To learn more click the name above.

Hydro Blast Max –

A 36″W x 30″D x 38″H side load, stainless steel parts washer. Uses only water to clean parts, Not compatible with abrasive. To learn more click the name above.

Hydro Blasting –

Is a process that propels pressurized air mixed with dry abrasive and water at a surface to clean or prep for paint. Also known as wet blasting, vapor blasting, liquid honing, aqua blasting, vapour blasting, vapor honing and slurry blasting.

High Volume Pressure Pump –

A high-pressure water pump that puts out more gallons per minute. Also has a polyurethane impeller.

L

Light Bar –

LED light bar that is mounted inside, at the top of a wet blast machine for better visibility.

Locking Caster –

A free-flowing wheel that is built with a locking mechanism designed to be attached at the bottom of large objects. This allows mobility and a stable locking position.

Liquid Honing –

Is a process that propels pressurized air mixed with dry abrasive and water at a surface to clean or prep for paint. Also known as wet blasting, vapor honing, aqua blasting, hydro blasting, slurry blasting, and vapour blasting.

Lifetime Warranty –

A warranty against defects in materials made by Vapor Honing Technologies and the execution of quality work that has no time limit to make a claim.

M

Micro Vapor Hone –

A 17″W x 13″D x 13″H front load, HDPE plastic vapor honing machine. To learn more click the name above.

Manual Touch Up –

Manual touch-up is an option that allows the user to switch from automated blasting to manual blasting on spots that did not turn out too well.

Media –

Is a consumable material such as abrasive.

Mobile Vapor Honing Unit –

A stainless steel mobile vapor honing unit that uses the same wet blasting process for outdoor. To learn more click the name above.

Mix Media –

When talking about mix media, it is when you mix two different types of abrasive together in a wet blast machine to perform the vapor honing process.

MOH –

A rough measurement of hardness used in mineralogy.

P

Peaks –

Are the areas of the substrate around the valley that push upwards upon impact.

Precision Regulator –

The highest level of accurately controlled airflow in order to keep a constant output of air. The precision regulator comes with 1/2″ NPT fittings.

Pinch Valve –

Regulate water and also keep the correct ratio of water and media.

PLC –

Also known as Programmable Logic Controller. This allows communication between each device and is great for industrial automation.

S

Silica –

A type of mineral that is colorless and is one of the main elements for most rocks. Silica is also a type of abrasive.

Silicosis –

A type of lung disease caused by inhaling small particles of silica. There are 3 types of silicosis; Chronic silicosis, Accelerated silicosis, and Acute silicosis. These 3 types of silicosis are determined by how much exposure you have to silica.

Stainless Steel Cabinet –

Wet blast machines that are built with stainless steel sheet metal. Rust resistant.

Standard Regulator –

A standard miniature airflow control that keeps a constant output of air.

Servo Driven Motion System –

An electronically controlled linear motion that is operated by a PLC.

Slurry Blasting –

Is a process that propels pressurized air mixed with abrasive and water at a surface to clean or prep for paint. Also known as wet blasting, hydro blasting, aqua blasting, vapor honing, liquid honing, and vapor blasting

Soda –

A type of abrasive also known as sodium bicarbonate is used in both wet and dry blasting. It is considered the softest type of abrasive in the abrasive blasting process. It has a MOH scale hardness of 2.5.

Silicon Carbide –

A type of abrasive used in both wet and dry blasting. Silicon carbide is angular shaped and is also an aggressive type of media. It has a MOH scale hardness of 9, which is right below diamond. Great for deep etching.

Steel Shot –

A type of abrasive used in abrasive blasting. The steel shot is spherical shaped and creates no etching.

Steel Grit –

A type of abrasive used in abrasive blasting. Steel grit is angular shaped and is also an aggressive type of media. This abrasive is great for removing paint fast.

Sandblasting –

A process that shoots pressurized air mixed with abrasive to shape a part or clean a surface. Sandblastings are also known as abrasive blasting and dry blasting.

Sandblast Cabinet –

A workstation that contains the dry blasting process. Also known as a dry blast cabinet.

Side Loading –

An accessing point, where you load and unload parts through the side of a vapor honing machine.

T

Tumbler –

A basket that sits inside a vapor honing machine whose purpose is to hold small parts as they are vapor hone. Manually and autonomously rotating tumble baskets are available.

Track and Cart System –

An add-on feature for our wet blast cabinet. A mobile piece where you can put heavy parts on the cart and is easily moved on the track.

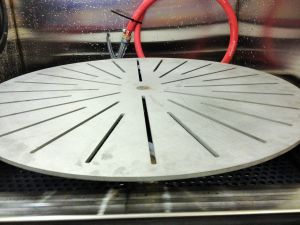

Turntable –

A round 1/4″ thick stainless steel sheet metal that sits inside a vapor honing machine. Its purpose is to have parts sit on top and easy turning.

V

Valleys –

The indentations in the substrate where the particles hits.

Vapor Honing –

Is a process that propels pressurized air mixed with abrasive and water at a surface to clean or prep for paint. Also known as hydro blasting, wet blasting, aqua blasting, slurry blasting, liquid honing, and vapor blasting.

Vapor Blasting –

Is a process that propels pressurized air mixed with abrasive and water at a surface to clean or prep for paint. Also known as hydro blasting, wet blasting, aqua blasting, vapor honing, slurry blasting, liquid honing, and vapour blasting.

Vapor Finish –

The term “vapor finish” refers to the finish achieved through vapor honing.

VH800P Base –

A 33″W x 30″D x 28″H HDPE light industrial plastic vapor honing machine. (Base Model) To learn more click the name above.

VH800P FL –

A 33″W x 30″D x 28″H HDPE industrial plastic vapor honing machine. (Fully Loaded Model) To learn more click the name above.

VH900 –

A 36″W x 24″D x 30″H industrial vapor honing machine. This machine can either be stainless steel, aluminum, or carbon steel. To learn more click the name above.

VH1000 –

A 36″W x 30″D x 38″H industrial vapor honing machine. This machine can either be stainless steel, aluminum, or carbon steel. To learn more click the name above.

VH1000 HD –

A 36″W x 30″D x 38″H commercial vapor honing machine. (Fully Loaded Heavy Duty) This machine can either be stainless steel, aluminum, or carbon steel. To learn more click the name above.

VH1200 OP –

A 40″W x 40″D x 40″H HDPE light industrial plastic vapor honing machine. To learn more click the name above.

VH2000 –

A 40″W x 40″D x 40″H industrial side load vapor honing machine. This machine can either be stainless steel, aluminum, or carbon still. To learn more click the name above.

VH3500 –

A 60″W x 30″D x 38″H industrial front load vapor honing machine. This machine can either be stainless steel, aluminum, or carbon still. To learn more click the name above.

VH4000 –

A 60″W x 48″D x 38″H industrial side load vapor honing machine. This machine has a guillotine door and can either be stainless steel, aluminum, or carbon still. To learn more click the name above.

VH900 Tumbler –

A 36″W x 24″D x 30″H stainless steel parts washer. This machine is only available as stainless steel with a tumble basket. To learn more click the name above.

W

Weekend Warrior –

A 33″W x 30″ x 28″H HDPE side load, hobbyist, plastic wet blast machine. To learn more click the name above.

Wet Blasting –

Is a process that propels pressurized air mixed with dry abrasive and water at a surface to clean or prep for paint. Also known as vapor blasting, hydro blasting, vapour blasting, liquid honing, vapor honing, and slurry blasting.