Vapor Blasting – Restoring History

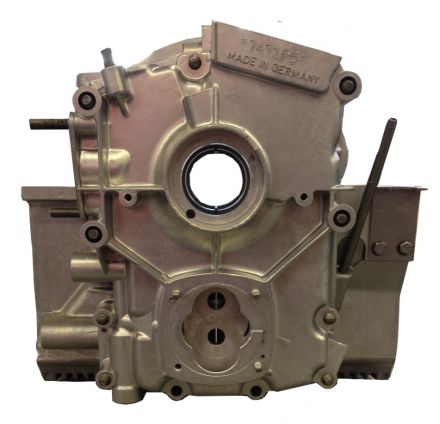

Vapor blasting is becoming a top priority for many automotive restoration shops. Why? With wet blasting you can clean restore and protect history with one simple step using wet blasting. With the flow based topography following nature of the wet slurry you can clean corrosion rust and years of grime and tarnish out of the tightest places in record time. Vapor blasting can even get into the valleys’ of most tough to reach area. Sooner or later this process will be the best way to go.

With vapor honing you do not have to worry about wearing a mask just to breath. No mask is required to vapor blast. No other process compares when it comes to not only cleaning but surface finishing parts for a rebuild. Dry blasting will remove precious marks and traits on engine and other components that add value to any restored car and wet blasting will simply clean over top of these marks of history. Contact us today to talk over your application and find a machine suitable for you.

- Provides an even and satin surface finish

- Can clean and restore most plastic and rubber parts

- Doesn’t remove casting marks or important identifiers

- Can prep surfaces for coatings

- Eliminates dust in your shop

- Low decibel operating levels makes part cleaning pleasant

- No chemicals or disposal needed

- Reduces abrasive consumption compared to dry blasting

- Can tailor surface finishes between customers