- Auto Parts Washer is backed up by the industry’s best LIFETIME WARRANTY

- 100 % built in the USA

- American tech support Monday – Friday

- Industrial machine built to last a lifetime

- Automatic parts washing cabinet

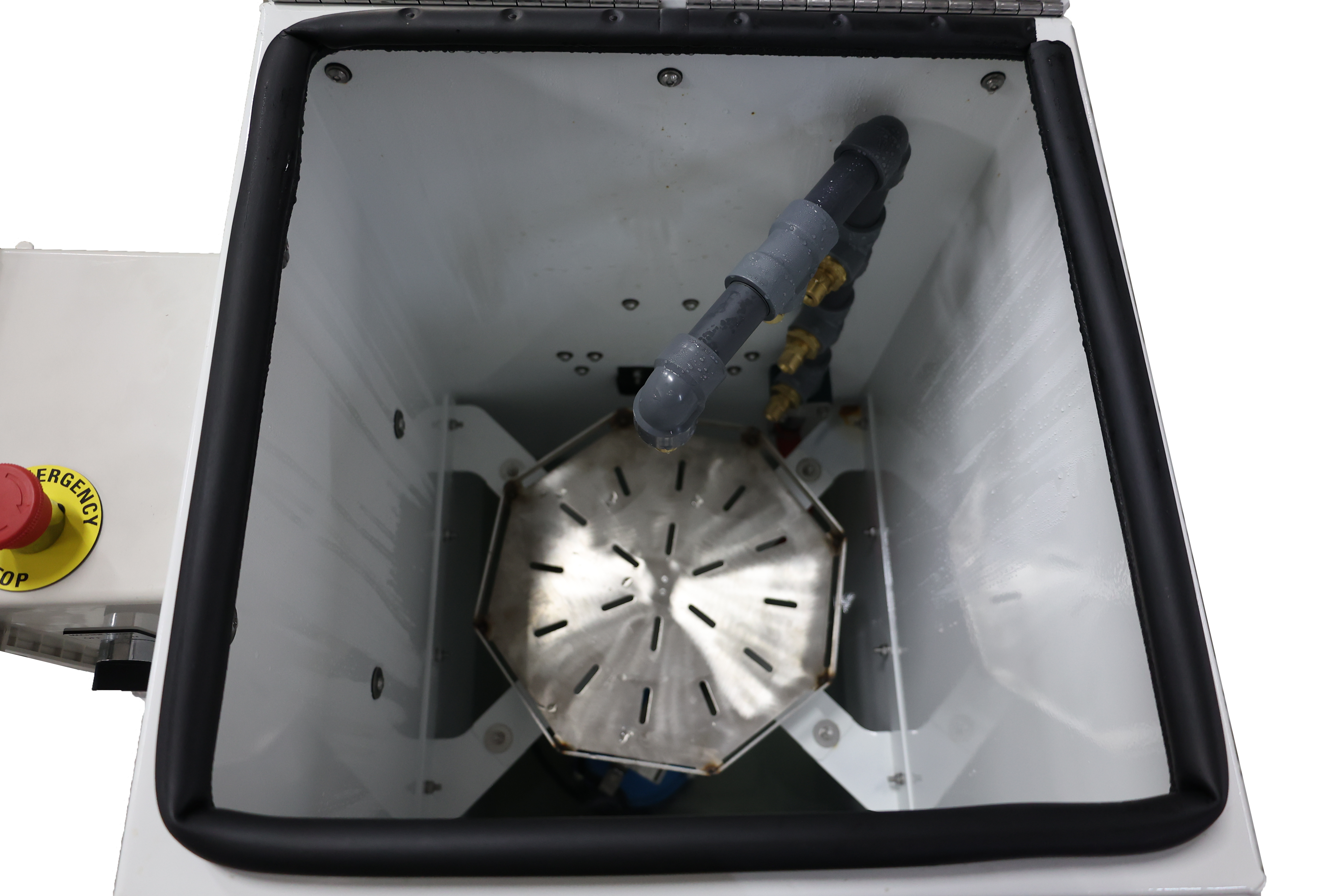

- High pressure pump

- Heater

- Turntable

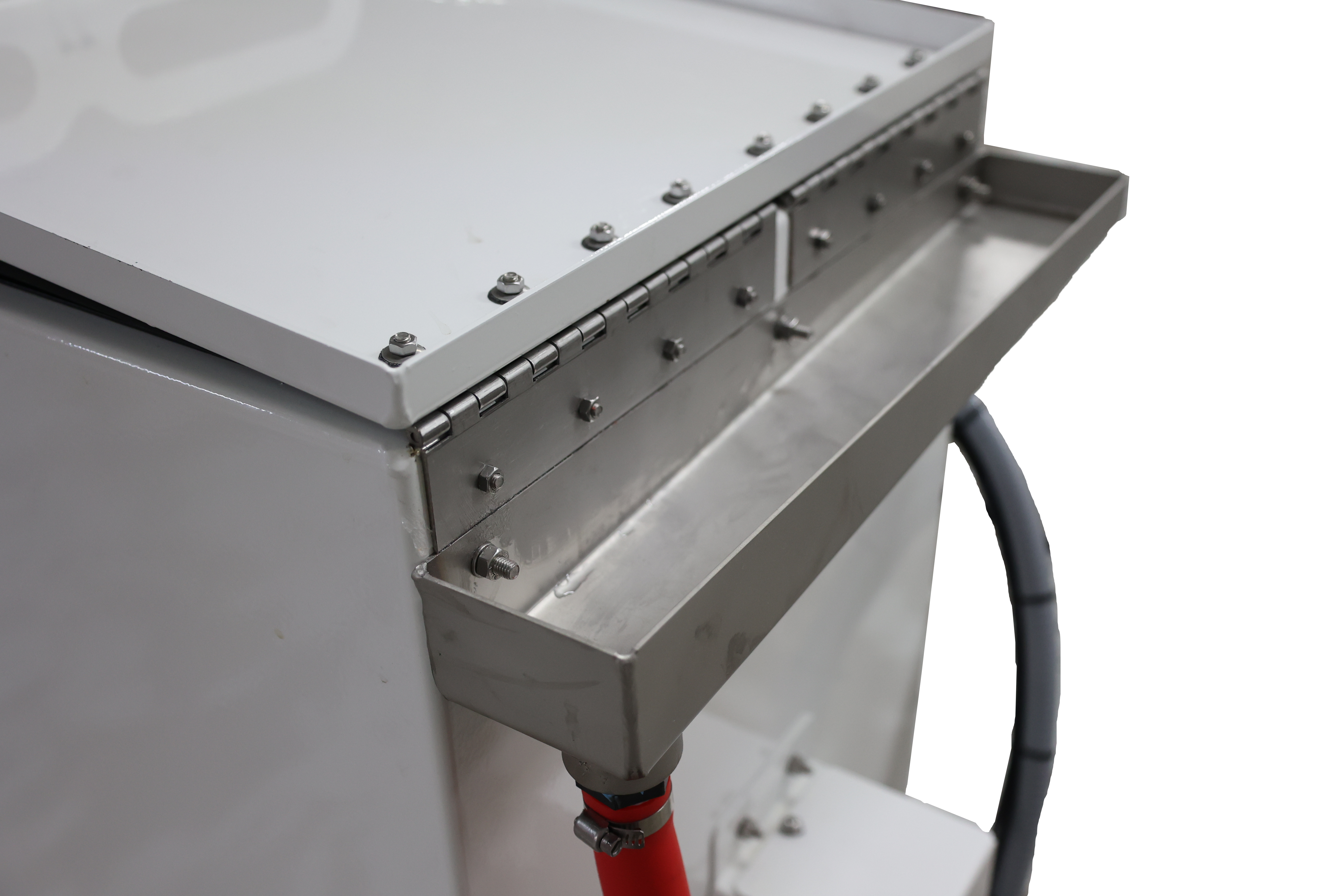

- Top load cabinet

- Designed to sit nicely on workbench

- 110 V single phase or 220V 3 phase optional

- Mild steel

| Overall Dimension | 17″ W x 17″ D x 40″ H |

| Power | 110 V Single Phase |

| Pump | High Volume Slurry Pump |

| Material | Mild Steel |

| System | Automatic |

| Assembly | No Assembly Required |

Optional Features

220V 3 phase

1. What’s the regular maintenance on vapor blasters as a whole?

2. How often do I change media and water?

3. Can I mix in something to stop freezing in the winter if I don’t have the unit in a place with heating?

4. What abrasives can I run in the vapor hone?

5. Does vapor honing take a lot of CFM?

1. Really just changing the water and abrasive that’s it. Consumables will last much longer in the wet systems due to the cushioning effect.

2. If you use it every other day I would change every month. If its occasional use you might go 2-3 months.

3. One of the most frequent questions that I don’t have a good solution for other than draining the machine if you know it will be sitting for more than a week in the cold weather. I personally try to minimize mixing any thing other than water and abrasive because it can create bad finishes if it throws out the PH of the slurry.

4. Any abrasive that you run in a dry blasting cabinet will run in a vapor hone machine.

5. It depends on what you define as a lot any wet cabinet can need 15-45 CFM to operate just depends on what machine model you choose.

If you like to see other machines in action or our before and after results, please visit our YouTube channel and subscribe

Click Below