Micro Vapor Hone

| Internal Working Dimensions | 17″ W x 13″ D x 13″ H |

| Power | No Power Needed |

| Abrasive Amount | 5 lbs. of Abrasives |

| Water Amount | 2 Gallons |

| Compressor Specs | Small Shop Compressor |

| CFM | 10-15 CFM |

| PSI | 60-70 PSI |

| Assembly | No Assembly Required |

-

Our Micro Vapor Hone is 100% built in the USA

-

American tech support Monday – Friday

-

Easy to handle wet blast nozzle provides maximum comfort and optimum performance

-

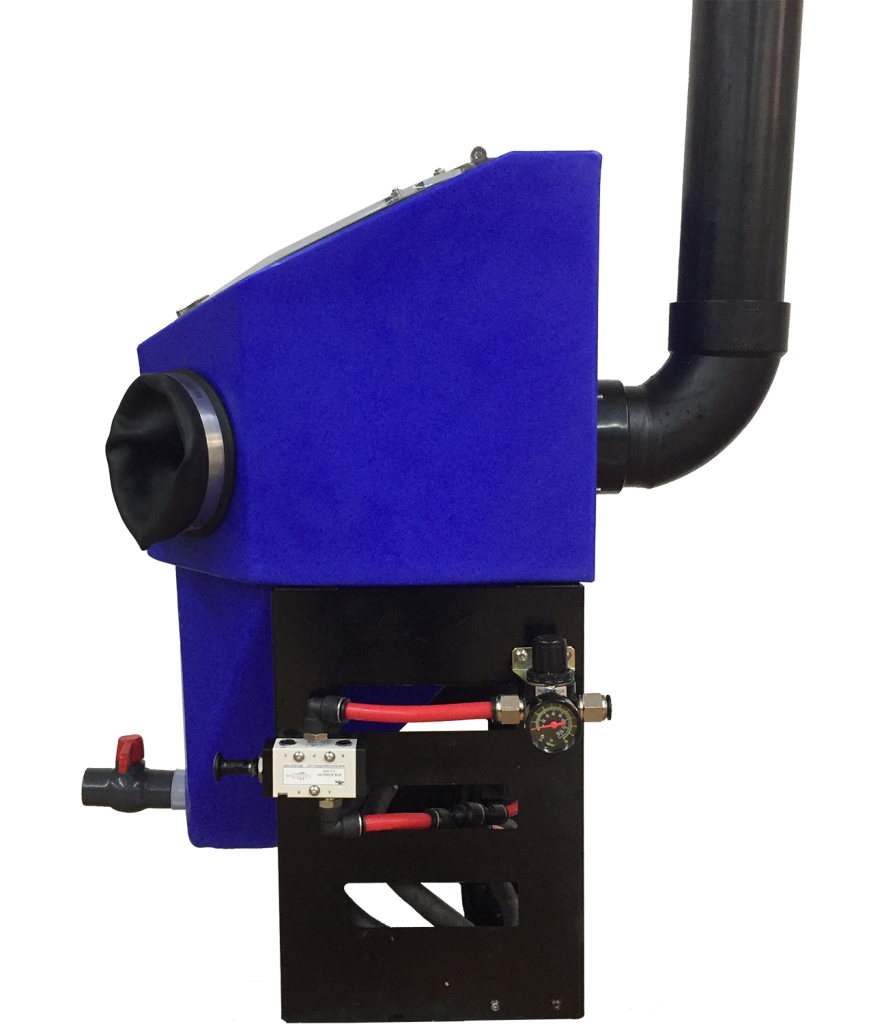

Tough and rugged HDPE designed cabinet will last a lifetime

-

14 Gauge metal powder coated base for great machine support and long life

-

Front 3/4″ NPT hopper drain valve for easy abrasive change out

-

Pull/ Push air switch for easy blast gun operation

-

Space saving design allows for easy location on your workbench or roll cart

-

Small machine footprint for easy placement in your busy workshop

-

Fully factory tested and assembled

-

Service connections all located on one side for easy hookup

-

Comes with standard regulator

-

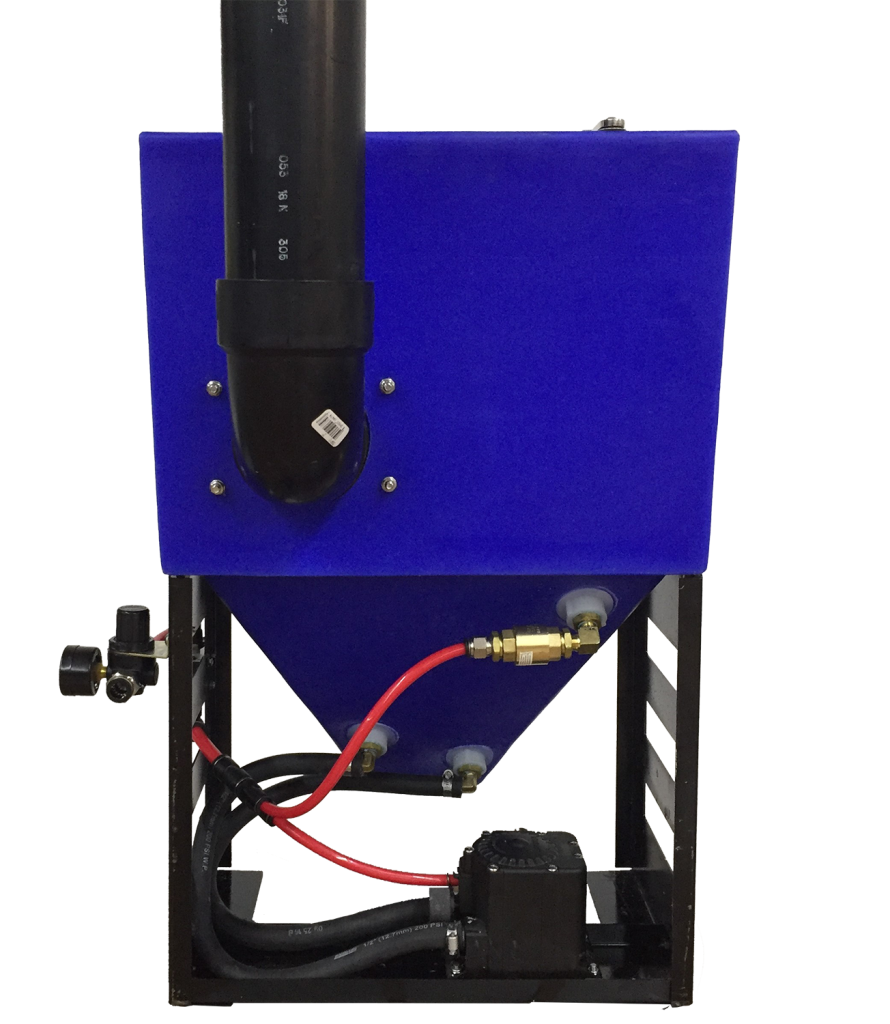

High performance pneumatic pump is fitted in the back for easy maintenance

-

All service supplies are located on the back of the cabinet for easy access

-

Tough and rugged HDPE designed cabinet will last a lifetime

-

Machine is designed to run completely off of compressed air no power needed

-

Machine is fitted with one main air supply regulator to regulate your cleaning process

-

Low maintenance hinges and latches for lifetime durability

-

Clear visibility of the entire blasting chamber for easier processing

-

Durable 40 mm thick seamless rubber gloves

-

Durable Lexan Window for easy replacement

Nothing hobby or weekend about this machine very well built product.

Seth H,

Florida

Budget friendly machine for all of us hobbyist while still getting a high level of customer support when needed.

Harry G,

Canada

1. What’s the regular maintenance on vapor blasters as a whole?

2. How often do I change media and water?

3. Can I mix in something to stop freezing in the winter if I don’t have the unit in a place with heating?

4. What abrasives can I run in the vapor hone?

5. Does vapor honing take a lot of CFM?

1. Really just changing the water and abrasive that’s it. Consumables will last much longer in the wet systems due to the cushioning effect.

2. If you use it every other day I would change every month. If its occasional use you might go 2-3 months.

3. One of the most frequent questions that I don’t have a good solution for other than draining the machine if you know it will be sitting for more than a week in the cold weather. I personally try to minimize mixing any thing other than water and abrasive because it can create bad finishes if it throws out the PH of the slurry.

4. Any abrasive that you run in a dry blasting cabinet will run in a vapor hone machine.

5. It depends on what you define as a lot any wet cabinet can need 15-45 CFM to operate just depends on what machine model you choose.

If you like to see other machines in action or our before and after results, please visit our YouTube channel and subscribe

Click Below