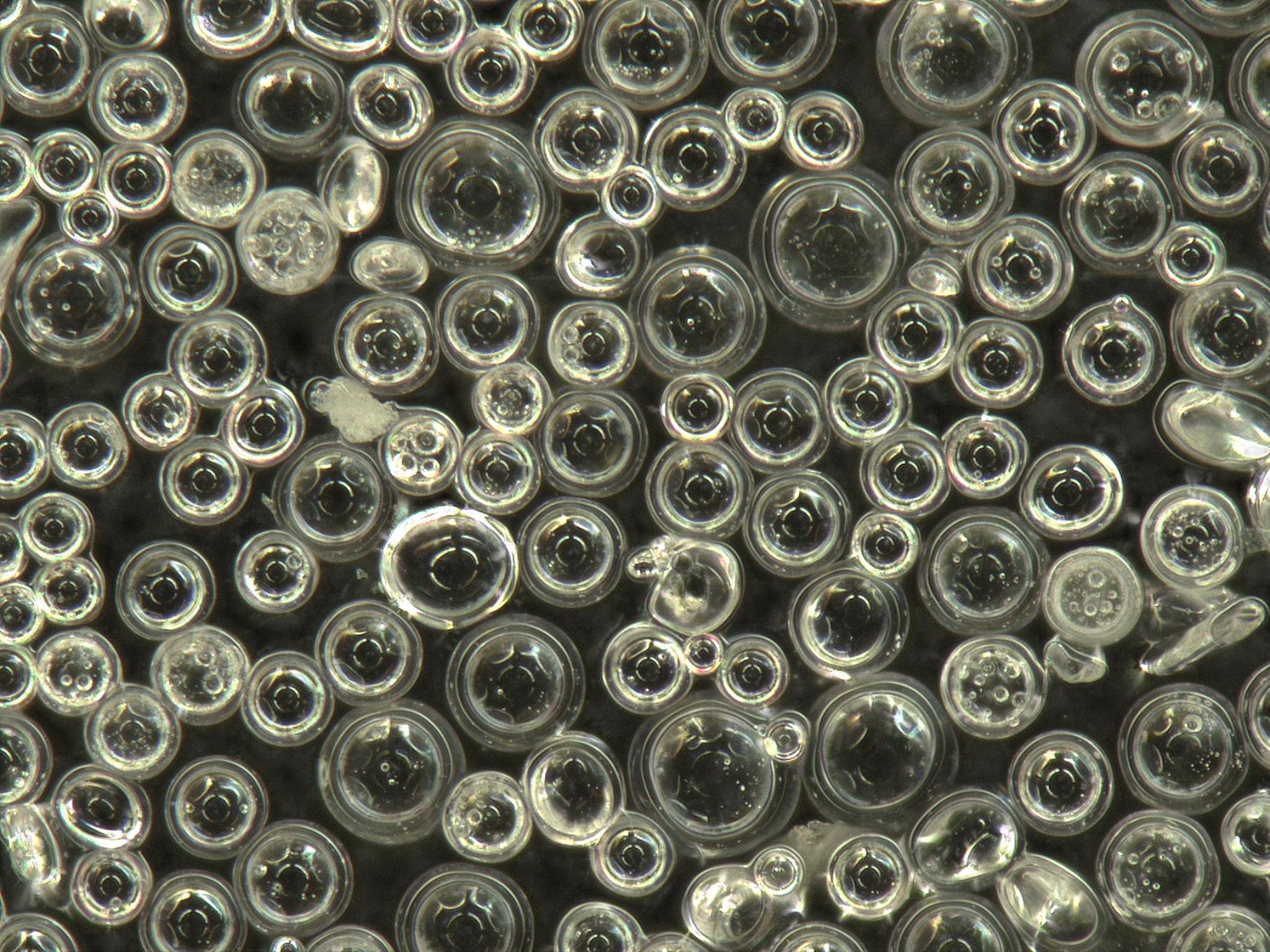

Glass Bead is the Most Popular Abrasive for Wet Blasting

Glass bead (pictured above) is commonly used in vapor honing, also known as wet blasting, for several reasons. Vapor honing is a surface finishing process that involves using a mixture of water, abrasive media, and compressed air to clean, deburr, and finish surfaces. There are many options for abrasives that can be used in this process. Glass Bead, however, remains one of the most common choices. Here are some reasons why glass beads are chosen as an abrasive media in vapor honing:

- Gentle Abrasion: The glass bead’s spherical shape makes the impact of the media far less severe than angular media like Aluminum Oxide. This makes them suitable for applications requiring a gentler abrasive action. Glass beads can remove surface contaminants without causing excessive material removal, making them ideal for delicate parts or surfaces.

- Non-Damaging to Substrates: Glass beads are non-reactive and less likely to cause damage to the substrate being processed. This is particularly important when working with softer materials or components with complex shapes, as it helps maintain the integrity of the part while achieving the desired surface finish.

- Cleaning and Peening: Glass bead blasting not only cleans surfaces but also imparts a peening effect. Peening involves imparting a controlled amount of cold work to the surface, which can improve resistance to fatigue and stress corrosion cracking. This makes glass bead blasting suitable for applications where both cleaning and surface enhancement are desired. However, it’s worth saying that ceramic bead is the superior option for peening surfaces.

- Reusability: Glass beads can be reused multiple times before they break down or wear out, making them a cost-effective option for certain applications. The ability to recycle and reuse the abrasive media contributes to the overall efficiency and economy of the vapor honing process. Glass Bead lasts up to a month of regular use before it needs to be changed out. Regular use is eight hours and five days a week. Also, ceramic bead lasts even longer than glass bead thanks to its denser properties.

- Consistent Finish: Glass beads provide a uniform and consistent surface finish. This is beneficial when aesthetics and precision are critical, such as in the aerospace, medical, or automotive industries, where components need to meet specific visual and dimensional standards.

You Can Learn About Glass Bead & Watch it in Action

You can Buy Glass Bead from Us

VHT is your ultimate source for surface finishing, offering a diverse range of abrasives, including high-quality glass beads. Our glass beads are meticulously selected to meet various industrial needs, providing a versatile and effective solution for gentle abrasion and consistent surface finishes. As your all-in-one destination, VHT not only specializes in glass beads but also offers a comprehensive selection of abrasives to address diverse applications. Count on VHT for reliable and top-notch abrasives, making us the trusted partner for achieving optimal results in your surface finishing processes.