-

100 % built in the USA

-

American tech support Monday – Friday

-

Industrial machine built to last a lifetime

-

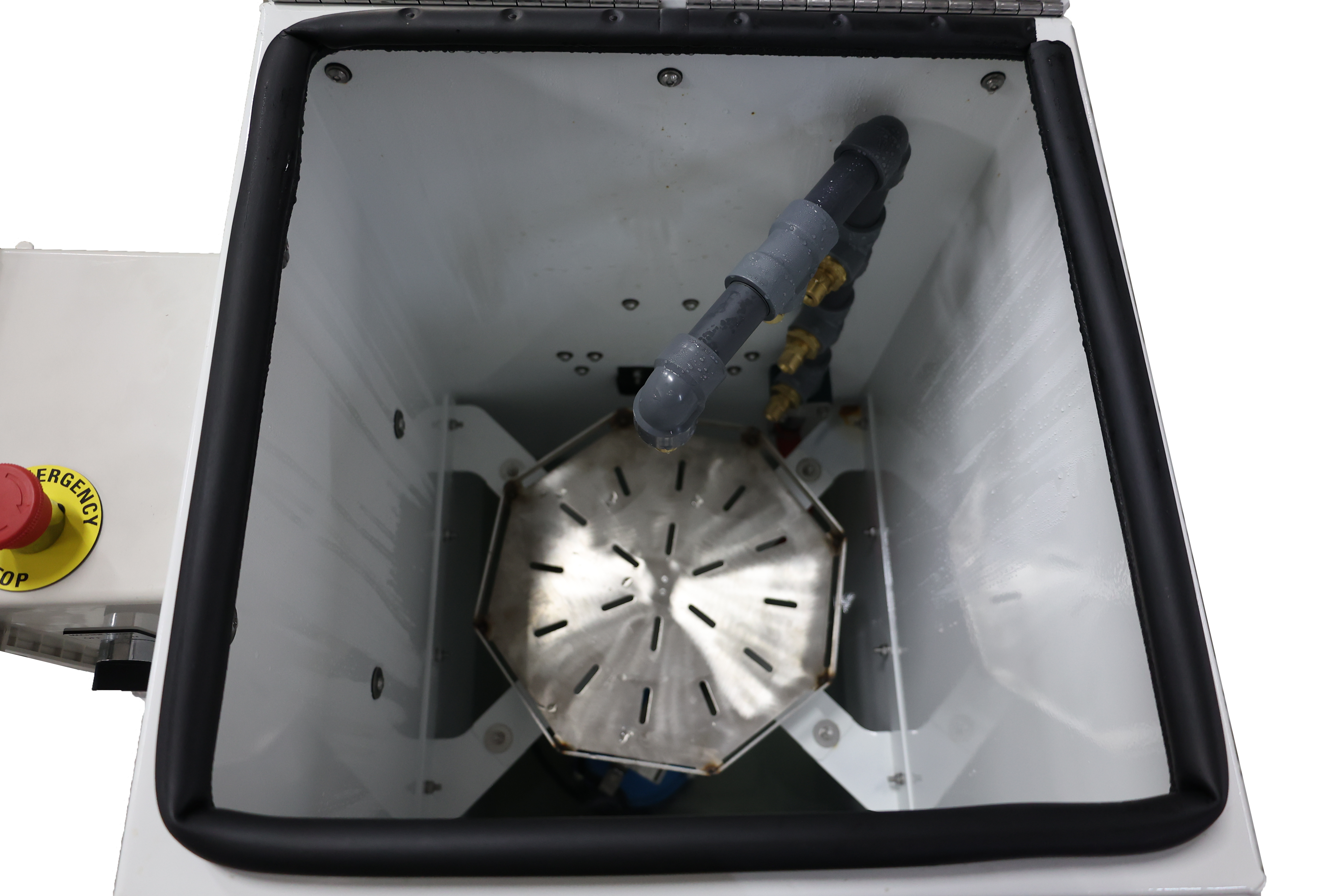

Automatic parts washing cabinet

-

12″ Turntable

-

Top load cabinet

-

Constructed of carbon steel

-

High volume pump

-

Simple timer control

-

110V Power, GFCI Connection

-

Machine exterior is painted Gunmetal Gray

-

Compact design for placement anywhere

| Overall Dimension | 17″ W x 17″ D x 40″ H |

| Power | 110 V Single Phase |

| Pump | High Volume Pump |

| Material | Mild Steel |

| System | Automatic |

| Assembly | No Assembly Required |

Company Reviews

Ben Angerstein.

515 Vapor Honing, LLC

Vapor Honing Questions

1. What are the primary components of a parts washing machine?

2. How does a parts washing machine operate?

3. What are the benefits of using a parts washing machine in industrial settings?

4. How does parts washing differ from Vapor Honing methods?

5. What factors should be considered when selecting a parts washing machine for specific applications?

1.The primary components of a parts washing machine typically include a cleaning chamber, a pump or agitation system, a filtration system, heating elements (if applicable), and controls for managing temperature, pressure, and cycle times.

2. Parts washing machines operate by spraying or immersing parts in a cleaning solution to remove contaminants such as oil, grease, dirt, and grime.

3. The benefits of using a parts washing machine in industrial settings include increased efficiency and productivity, improved cleaning effectiveness, reduced labor costs, better environmental compliance through proper waste management.

4. Vapor honing, also known as vapor blasting or wet blasting, differs from parts washing methods by combining abrasive media with water and compressed air to simultaneously clean and finish parts. Making Vapor Honing important where visual aesthetics come in.

5. Factors to consider include the size and shape of the parts being cleaned, the type and level of contaminants to be removed, the desired cleaning method (e.g., immersion, spraying, ultrasonic), the availability of space and utilities (such as water, electricity, and drainage), and the required throughput and cycle times.