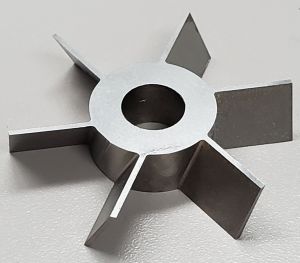

Beadblasting parts after wire EDM

Beadblasting after wire EDM has been the traditional means to post processing these types of parts.

Most CNC centers have historically used beadblasting as a post process means to either finishing, coating preparation or lightly de burring machined parts. The problems associated with traditional dry blasting are many.

Not only is beadblasting aggressive on the part surface itself but it is more harmful to the operators running these dusty death traps as well.

Listed in the next paragraph we will identify a few areas of concern on the parts being processed through beadblasting vs vapor honing.

Over the years at Vapor Honing Technologies we have been able to identify a few major points of discussion when comparing dry blasting with vapor honing on machined parts. The points of concern are listed below.

- Edge rolling occurs when dry beadblasting ( vapor honing allows for a better flow across the part decreasing edge rolling on all metals or plastics due to the decreased impact.)

- Heightened surface roughness figures ( vapor honing decreases the surface impact due to the water cushion between the part and the abrasive.)

- Dry blasting impacts the surface harder increasing the chances of abrasive impregnation into the substrate ( vapor honing uses water with abrasive suspended decreasing surface impact and lessening the chance of abrasive impregnation into the substrate)

We at Vapor Honing Technologies take our job very seriously when helping you find the right equipment for your processing needs. Let us take a moment to help you spec out a process for your next application and we promise you’ll be glad you did.

Call our office: (828)202-5563

Email Us: info@vaporhoningtechnologies.com

Subscribe to our Youtube Chanel: https://www.youtube.com/user/RiceRelics?sub_confirmation=1