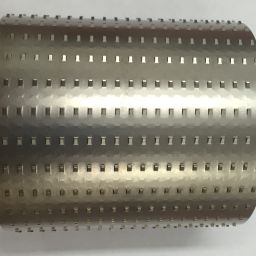

De burring & Finishing CNC Parts with Wet Blasting

The use of the wet blasting process to de burr and or finish CNC parts is becoming a big hit. The reason for this big hit is because of the flow based nature of the slurry. It gently runs across a delicate surface helping retain its form and function. This process helps speed up operations in the de burring department helping remove smaller burrs. It also has been used in heat treat departments removing heat treat scale preparing for a coating. Lastly, wet blasting has been used in providing consistent and repeatable surface finishes on many aesthetic parts.

- Provides an even and satin surface finish

- Can de burr and surface finish parts simultaneously

- Prep surfaces for coatings while holding tight tolerances

- Eliminates dust in your shop

- Low decibel operating levels makes part cleaning pleasant

- Reduces abrasive consumption compared to dry blasting

- Can tailor surface finishes between customers