How to Choose and Buy a High-Quality Vapor Blasting Cabinet

How long does it take you to strip grease off a hub cap? Have you spent hours making sure that motorcycle chrome is perfectly clean? How about all the time and effort you’ve spent getting that satin stainless finish just right?

If this sounds familiar, you can understand the frustration. Scrubbing and cleaning materials by hand is a waste of your time.

There’s a better and faster way to strip unwanted grime, paint, and grease from surfaces. Vapor blasting is the perfect solution for business or hobby projects.

The right vapor blasting cabinet can save your business time and money. Keep reading to find out how to select the right vapor blasting cabinet for you.

View Our Video On How To Choose The Right Machine

What Is Vapor Blasting?

Vapor blasting is a surface preparation process used on various materials throughout many different industries. Vapor blasting is an excellent way to clean large and small objects, like various car parts or machinery pieces. It’s also used to get the desired finish on many different metal types also what we call a surface finish.

Vapor blasting is sometimes referred to as wet blasting, aqua blasting, vapor honing, or liquid honing.

You may be familiar with the dry version of blasting rust or paint off. This method is similar to vapor blasting but differs in a few important ways.

How Does a Wet Blasting Cabinet Work?

Wet blasting cabinets combine the use of water, abrasive media, and pressure to strip unwanted materials from metal surfaces and objects.

A cabinet combines these three elements by providing a nozzle for media blasting and a water hose. The cabinet creates a sealed environment for vapor blasting by enclosing the work area.

Consumers can use the rubber gloves attached to the unit to get their work completed. Wet blasting cabinet users can also view their jobs by a window provided on the top or side of the cabinet.

Once the media and water is added to the unit, the blasting can begin. The nozzle is controlled by the user through the attached rubber gloves. Most cabinets have a foot pedal to control slurry flow from a pump located in the sump during the process as well.

Completing wet blasting jobs in a sealed-off cabinet environment has many advantages. Keep reading to find out more.

A Gentle Clean

Softer materials are safe to clean in a wet blasting cabinet. Because the media is paired with water, its impact is less harmful to materials. From chrome wheels to jewelry, wet blasting media won’t harm softer metals or even plastics.

Less Dust

When paired with abrasive media, water absorbs its dust. There’s much less loose material flying around during the blasting process. Water also washes away any residue left after blasting.

This means your end product will come out cleaner. This eliminates the need to clean after blasting other than a simple rinse with water and dry the part with compressed air.

Efficiency

The media and water solution (also called slurry) create a more efficient process of cleaning or stripping materials. Abrasive media is held to surfaces for a longer period of time when combined with water.

During dry blasting (media without water) abrasive materials bounce off surfaces and take longer to do their job.

Slurry increases the number of materials removed using less time than dry blasting processes.

Another advantage to some vapor blasting cabinet design is the ability to recycle water within the unit. This saves on cost and eliminates unnecessary water waste.

Why Is Vapor Blasting Better Than Sandblasting?

Sandblasting is another common way to remove stubborn materials and refinish products. While sandblasting can be effective, vapor blasting is more efficient and less harmful to both the part being blasted and the person doing the blasting.

Sandblasting uses abrasive media, air pressure, and heat without a water agent. It is a great way to remove paint and other materials but is not as efficient as vapor blasting.

Using a sandblasting cabinet keeps dust and media contained. This saves you the inconvenience of cleaning dust off everything in your shop. It also keeps you and those around you from breathing in toxic dust.

But when you remove that item from a sandblasting cabinet, it needs to be dusted off and cleaned. While it doesn’t necessarily pose a major health risk, it’s another tedious step in the process.

What to Look for in a Vapor Blasting Cabinet?

Choosing the right vapor blasting cabinet isn’t a complicated process. It should, however, be approached with research and thought.

What’s The CFM?

One of the most important factors in deciding which cabinet you need is the CFM, or cubic force per minute. The CFM number tells you how much force is behind the air and media coming out of the blasting hose.

If the CFM isn’t high enough, the job won’t get done. If the CFM is too high for your compressor the machine will not operate effectively.

It’s important to make sure your equipment will work with the existing systems in your shop.

CFM is created by using an external air compressor. If you’re unable to provide the right CFM, the hydro blasting cabinet won’t work as it should.

What Can You See?

You need to have a great view of your projects. Another advantage to vapor blasting over sandblasting is the ability to wipe the windows clean.

A smaller vapor blasting cabinet may not have a window wiper, but it should have a good-sized window. A wet blasting cabinet may also come with a window wiper to clear away water or media blocking your view.

Some high-end vapor blasting cabinets even come with LED lighting for better visibility. The more light you have to see your job, the faster (and better) things get done.

How Much Water Does It Use?

The answer to this question depends on the size of your hydro blasting cabinet. Most hydro-blasting cabinets won’t need a drain nearby. They are set up to either recycle and collect their own water.

Recycled water is often filtered and used to help clear the viewing window.

When you’ve finished your job, you should be able to easily collect used water and media from your wet blasting cabinet. Check with your city or county to find out how and where to dispose of it.

Smaller hydro blasting cabinets only take about two gallons of water. Large hydro blasting cabinets require 25 gallons of water to operate. If you’re looking for something in between the two extremes, many wet blasting cabinets take 15 gallons of water to get the job done.

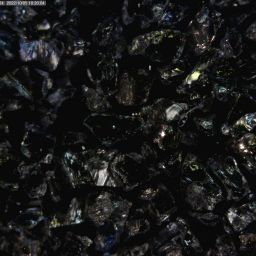

How Much Media Does It Use?

Similar to the amount of water used, this answer depends on the wet blasting cabinet design and size. If the water requirements are smaller, so is the amount of media.

The smallest hydro blasting cabinets take 4-5lbs of abrasive media. Medium ranged wet blasting cabinets require 10 to 20lbs of abrasive. A large wet blasting cabinet takes about 25lbs of abrasive to work. This abrasive is however reused so its not a one and done process saving you thousands of dollars over a year.

Is Assembly Required?

Assembling a vapor blasting cabinet isn’t like furniture. Missing one small assembly step could result in harm to the machine or its users.

Unless you want to spend additional time piecing together your wet blasting cabinet, it should come to you already assembled.

When a company assembles a blasting cabinet, they use an assembly line and trained professionals to do the job. This ensures the best seal for the unit, doors, and viewing windows and an overall better operating machine.

Where Was It Made?

When you support businesses that manufacture products in the United States, you’re supporting the economy. You’re investing in the future of the United States by buying made in America products.

American-made products are held to American standards of production. They are also subject to U.S. working standards for employers. This means your hydro blasting cabinet was made in an ethical way.

A vapor blasting cabinet made in the United States lessens your carbon footprint. The United States adheres to certain environmental manufacturing guidelines. Buying machines made in the USA means you can feel good about your purchase.

Vapor Blasting Cabinet Options and Specs

Still not sure which wet blasting cabinet is best for you? Here’s a look at some different types of vapor blasting cabinets to help you decide.

Mirco Vapor Hone

If the vapor blasting cabinet cost has kept you away in the past, check out this small, yet powerful option.

For smaller items, consider the Micro Vapor Hone. This machine’s size is smaller but it can still handle heavy items. From soft, delicate metals to heavy-duty small-in-size projects, the Micro Vapor Hone can get the job done.

The Micro Vapor Hone needs 10 – 12 CFM max to operate. A small air shop compressor works just fine for this machine. Other than that there’s not power needed and doesn’t require assembly.

Operators will need two gallons of water and four to five pounds of abrasive media for this machine.

Inside dimensions are 17″ wide x 13″ deep x 13″ high. The Mico Vapor Hone has outside measurements of 20″ wide, 14″ deep, and 22″ high.

The Weekend Warrior

This vapor blasting cabinet is a perfect mid-sized hobbyist option. The Weekend Warrior comes with a right-side loading door.

It has convenient access to the pressure hose connection for ease of access. This open-loop wet blasting cabinet has a freshwater connection located in the back of the unit.

Window wipers and in-box LED lighting come standard with the Weekend Warrior. It also comes with a high-volume slurry pump, polymer pump impeller, boron carbide blasting gun tips, and much more.

Add-on options include rubber-lined walls and a 1,000lbs capacity stainless steel turntable.

Internal dimensions are 33″ wide x 30″ deep x 28″ high. On the outside, the Weekend Warrior takes up 36″ wide x 35″ deep x 5′ 8″ high.

This vapor blasting cabinet takes 15 Gallons of water for operation and 25lbs of abrasive.

CFM measures 15-20 which gives 120 PSI max pressure.

Ecoline 3630

If you want an industrial-grade product without all the expensive bells and whistles, the Ecoline 3630 is a good fit for you.

This vapor blasting cabinet is made from fully welded tubular material. It has great features like internal LED lights, window wiper, and foot pedal operate nozzles. The Ecoline also features high-volume slurry pump and baron carbine blasting gun tips.

The Ecoline 3630 can be closed or open loop with your water source-you decide. Buyers can add on a rubber lining, stainless steel table, and a closed-loop rinsing sediment tank.

Internal Working Dimensions are 36″ wide x 30″ deep x 38″ high with overall dimensions of 40″ wide x 35″ deep x 7’ high.

You’ll need a whopping 25 gallons of water and 25lbs of abrasive to operate the Ecoline 3630. This vapor blasting cabinet requires a 7.5Hp or larger air compressor and gives 120 PSI max air pressure.

The Best Vapor Blasting Cabinet for You

Selecting a vapor blasting cabinet doesn’t have to be complicated or overly expensive. From jewelry to engines, you can find the right fit for your needs.

By deciding which features are most important to you, you can select the best option for your space, budget, and jobs.

If you’re short on space, small yet powerful options make a vapor blasting cabinet a reality for your home or shop. If you need an industrial-grade product without extra features, there’s something for you as well.

At Vapor Honing Technologies, we are here for all your vapor blasting needs. From replacement parts to cabinets, we will provide expert advice and service. All of our products are made and tested in the United States.

Give us a call at 828-202-5563. Check out our website for info about products, testimonials, and our trade-in program.