-

100 % built in the USA

-

American tech support Monday – Friday

-

Industrial machine built to last

-

Hands free cleaning

-

High volume pump

-

Adjustable heater, max 120°F

-

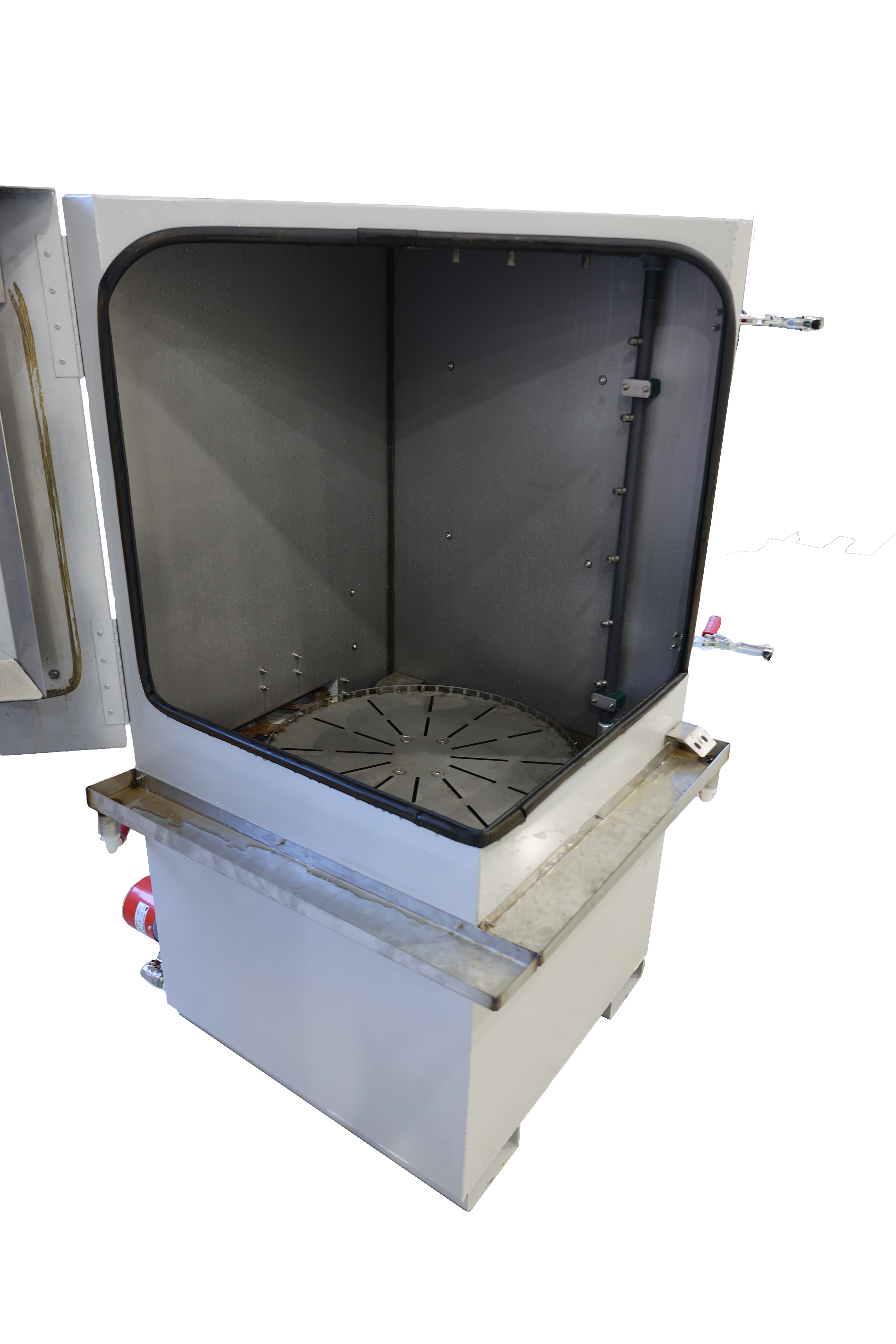

Large front swing door

-

Space saving self contained design

-

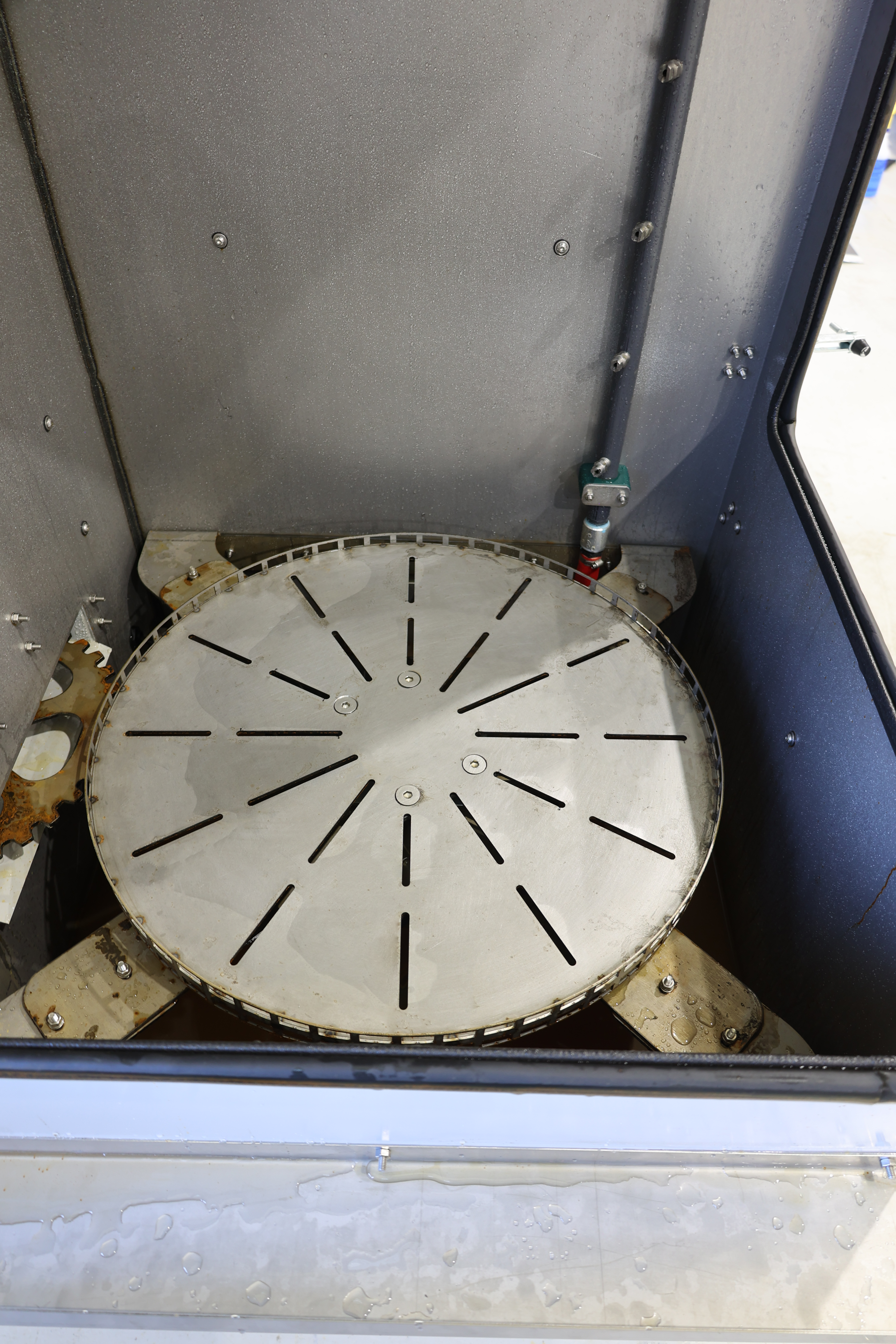

Large 24″ turntable

-

Multiple spray jets for maximum coverage

-

Aqueous based detergents can be used

-

Machine exterior is painted Gunmetal Gray

-

220V single phase for easy hookup

-

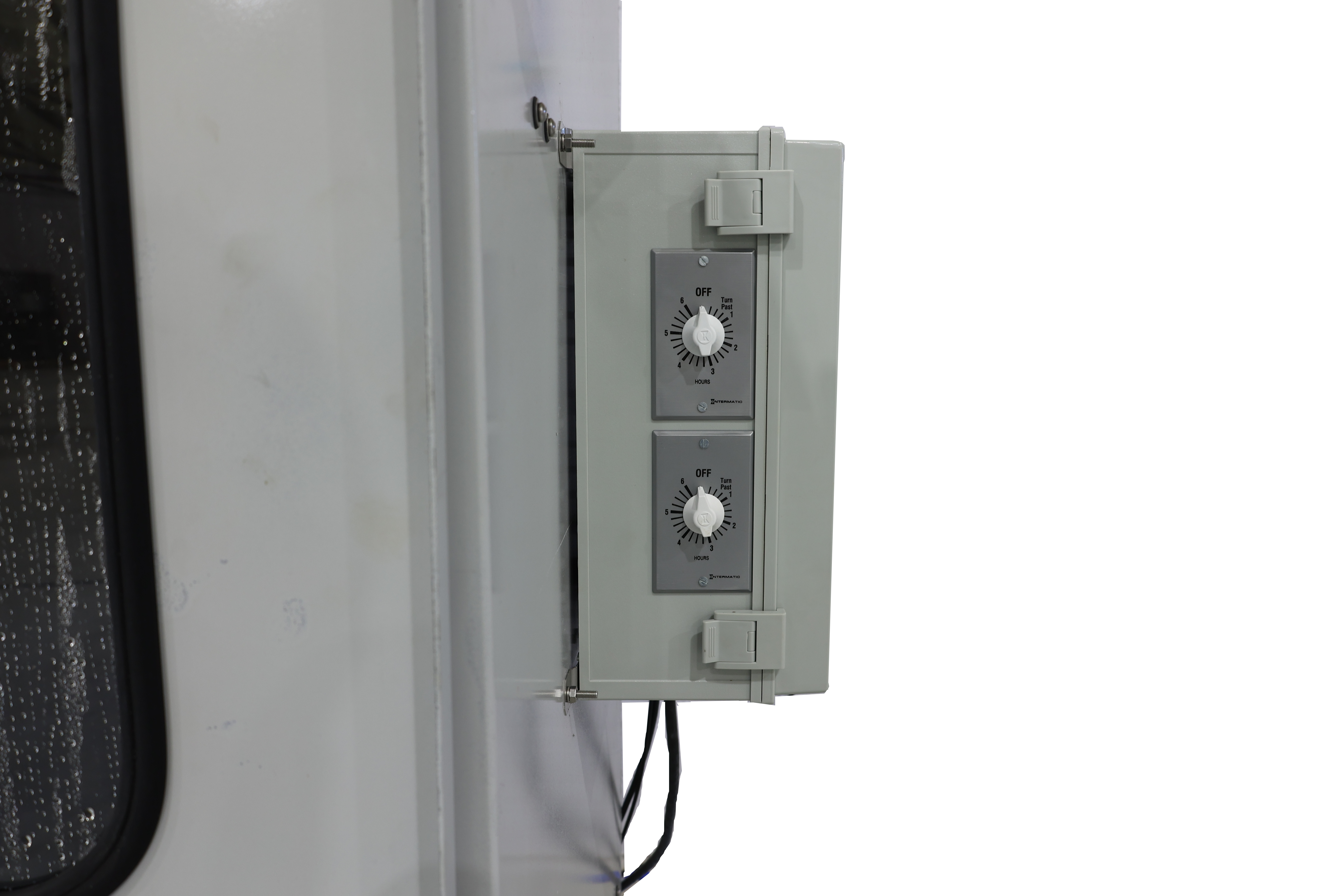

Simple timer controls

-

Temperature adjustment on heater

-

Made of carbon steel

-

Main drain located on rear

-

Forklift runners for easy maintenance

-

Large viewing window

| Internal Working Dimension | 24″ TT x 30″ H |

| Power | 220V Single Phase |

| Optional Consumables | Aqueous Detergent, Corrosion Inhibitor, Anti-Microbial |

| Water Amount | 18 Gallons |

| Pump | High Volume Pump |

| Gun Tips | Boron Carbide Blasting Gun Tips |

| Compressor Air Requirement | No Air Required |

| Assembly | No Assembly Required |

Optional Features

Rubber Blasting Mat

1. What are the primary components of a parts washing machine?

2. How does a parts washing machine operate?

3. What are the benefits of using a parts washing machine in industrial settings?

4. How does parts washing differ from Vapor Honing methods?

5. What factors should be considered when selecting a parts washing machine for specific applications?

1.The primary components of a parts washing machine typically include a cleaning chamber, a pump or agitation system, a filtration system, heating elements (if applicable), and controls for managing temperature, pressure, and cycle times.

2. Parts washing machines operate by spraying or immersing parts in a cleaning solution to remove contaminants such as oil, grease, dirt, and grime.

3. The benefits of using a parts washing machine in industrial settings include increased efficiency and productivity, improved cleaning effectiveness, reduced labor costs, better environmental compliance through proper waste management.

4. Vapor honing, also known as vapor blasting or wet blasting, differs from parts washing methods by combining abrasive media with water and compressed air to simultaneously clean and finish parts. Making Vapor Honing important where visual aesthetics come in.

5. Factors to consider include the size and shape of the parts being cleaned, the type and level of contaminants to be removed, the desired cleaning method (e.g., immersion, spraying, ultrasonic), the availability of space and utilities (such as water, electricity, and drainage), and the required throughput and cycle times.

Company Reviews

A happy business owner her. Marshall Plumb

It has increased revenue by 50% on used parts and components

We have the weekend warrior machine

I would recommend this for anyone wanting to renew anything corroded or rusted to absolutely renew

Thank you Vapor Hone, JB

Great product, fantastic customer service, quick turnaround and constant upgrades to the product line.

Since the purchase of my machine many years back, it has been the absolute best purchase I have ever made as an addition to my motorcycle restoration and rebuild shop. The quality construction and high caliber components totally changed the way my motorcycles came out. I noticed and so did my customers!

Over the years, I have needed some spare parts and consumables. Anytime I placed and order my requests were answered very quickly. Communication was never an issue and all orders were shipped out promptly and tracking info was always provided.

My machine has been used extensively over the years, and with Vapor Honing Technologies constant innovation, it has allowed me to retrofit my machine with some of the newest upgrades.

It continues to make my machine the most useful tool in my shop.

Overall, the buying experience and the ownership experience has made this a game changer for the overall quality of my restorations.

I consider it the best tool purchase I have ever made!

David Crandall

Birmingham, Alabama