-

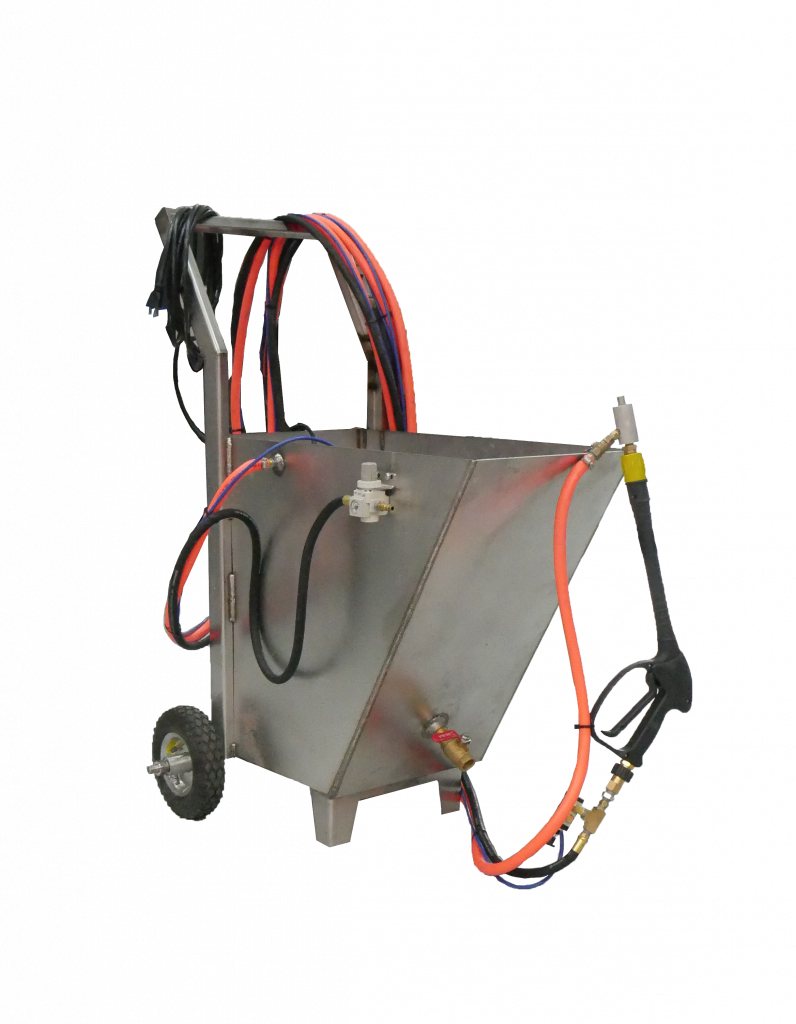

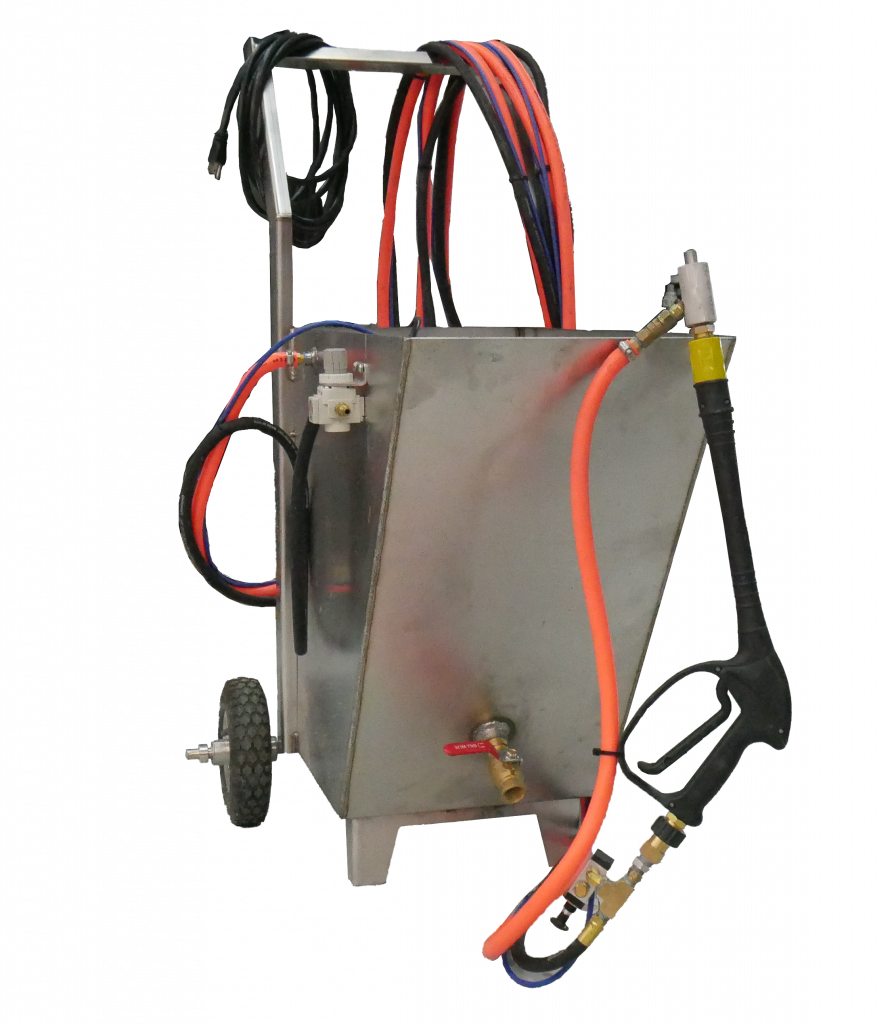

The Mobile Unit from Vapor Honing Technologies is backed up by the industry’s best LIFETIME WARRANTY

-

100% built in the USA

-

American tech support Monday – Friday

-

Model is built to last

-

304 Stainless steel 12 gauge

-

Comes with standard regulator

-

Great for outdoor use

-

Flexibility to travel anywhere and blast

-

A full charge of abrasive allows for 45 minutes to an hour of blasting

| Regulator | Standard |

| Power | 110V Single Phase |

| Abrasives Amount | 25lbs. of Abrasive |

| Water Amount | 18 Gallons |

| Compressor | 30 gallon Gas Compressor |

| CFM | 19 CFM |

| PSI | 100-130 PSI |

| Assembly | No Assembly Required |

Call Us Today!

For more information about the Mobile Vapor Honing Unit, call our sales team today at (828) 202-5563!

Company Reviews

A happy business owner her. Marshall Plumb

It has increased revenue by 50% on used parts and components

We have the weekend warrior machine

I would recommend this for anyone wanting to renew anything corroded or rusted to absolutely renew

Thank you Vapor Hone, JB

Great product, fantastic customer service, quick turnaround and constant upgrades to the product line.

Since the purchase of my machine many years back, it has been the absolute best purchase I have ever made as an addition to my motorcycle restoration and rebuild shop. The quality construction and high caliber components totally changed the way my motorcycles came out. I noticed and so did my customers!

Over the years, I have needed some spare parts and consumables. Anytime I placed and order my requests were answered very quickly. Communication was never an issue and all orders were shipped out promptly and tracking info was always provided.

My machine has been used extensively over the years, and with Vapor Honing Technologies constant innovation, it has allowed me to retrofit my machine with some of the newest upgrades.

It continues to make my machine the most useful tool in my shop.

Overall, the buying experience and the ownership experience has made this a game changer for the overall quality of my restorations.

I consider it the best tool purchase I have ever made!

David Crandall

Birmingham, Alabama

Vapor Honing Questions

1. What’s the regular maintenance on vapor blasters as a whole?

2. How often do I change media and water?

3. Can I mix in something to stop freezing in the winter if I don’t have the unit in a place with heating?

4. What abrasives can I run in the vapor hone?

5. Does vapor honing take a lot of CFM?

1. Really just changing the water and abrasive that’s it. Consumables will last much longer in the wet systems due to the cushioning effect.

2. If you use it every other day I would change every month. If its occasional use you might go 2-3 months.

3. One of the most frequent questions that I don’t have a good solution for other than draining the machine if you know it will be sitting for more than a week in the cold weather. I personally try to minimize mixing any thing other than water and abrasive because it can create bad finishes if it throws out the PH of the slurry.

4. Any abrasive that you run in a dry blasting cabinet will run in a vapor hone machine.

5. It depends on what you define as a lot any wet cabinet can need 15-45 CFM to operate just depends on what machine model you choose.