Sodium Bicarbonate: An in-Depth Look at Soda Blasting Media

Did you know that sodium bicarbonate is an antidote that can save people from poisoning? In some cases, doctors use it to reverse the symptoms of acidosis in patients. In theory, it may even help decrease certain cases of lung injuries.

However, the medical and pharmaceutical sectors aren’t the only users of sodium bicarbonate. It’s also in bio-pesticides, which are pesticides that use natural ingredients.

What’s more, sodium bicarbonate was a key player in the restoration of the Statue of Liberty. This project used more than 100 tons of soda blasting media. Many experts say that this restoration propelled soda blasting to popularity.

What exactly is sodium bicarbonate, though, and how does it work as a blasting media? Why is it ideal for surface cleaning and preparation, and what applications can you use it for?

This guide on soda blasting will answer all these questions and more, so be sure to keep reading!

What Is Sodium Bicarbonate?

Sodium bicarbonate also goes by the name “baking soda” and “sodium hydrogen carbonate.” Its chemical formula is NaHCO₃, wherein “Na” is sodium (salt), “H” is hydrogen, “C,” is carbon, and “O” is oxygen. It’s a type of salt that, when mixed with water, breaks down to form sodium and bicarbonate.

Baking soda has so many uses outside of food that it’s become a $1.73-billion industry. Sodium bicarbonate is in antacids and supplements. You’ll also find it in personal care products, such as mouthwashes and deodorants.

In the surface finishing sector, sodium bicarbonate works as a gentle abrasive medium. The soda used in soda blasting isn’t as aggressive as other abrasive agents, such as sand.

The sodium bicarbonate used in soda blasting isn’t the same “baking soda” used in food, though. Manufacturing companies produce sodium bicarbonate specifically for soda blasting applications.

How Does Sodium Bicarbonate and Soda Blasting Work?

Soda blasting is like traditional sandblasting, except that it’s gentler on surfaces.

Soda is “gentler” as it’s a mild abrasive with a Mohs hardness rating of only 2.5. That’s almost four times gentler than aluminum oxide, which has a Mohs hardness number of 9. This is also why dentists use baking soda in dental treatments.

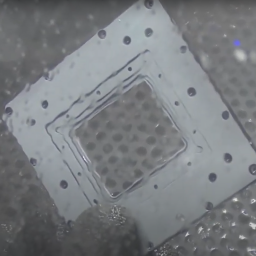

As for blasting applications, you can use soda in both dry and wet blasting equipment. In dry soda blasting, compressed air blasts soda particles against a surface.

By contrast, wet soda blasting uses sodium bicarbonate and pressurized water. Wet blasting, also called “vapor honing,” specifically uses “slurry.” Slurry refers to a mixture of blasting media (such as sodium bicarbonate) and water.

Which Applications Can You Use Soda Blasting Media for?

Soda blasting provides a non-destructive method for surface preparation and cleaning. Soda’s milder abrasive effects allow for a surface’s profile to remain intact. This is one of sodium bicarbonate’s characteristics that help prevent substrate damage.

On that note, let’s take a closer look at some of the most common soda blasting applications.

Surface Cleaning

One of the primary uses of soda blasting is to clean surfaces such as engine parts, engine internals, and plastic. For starters, soda blasting media make it easier to dissolve dirt and grease in water. Soda’s mild abrasiveness also gives it the grit to displace particles from surfaces.

Soda blasting works even better if used with pressurized water. The pressure amplifies the cleaning prowess of the salt. The pressurized water also works as a cleaner itself, as it dislodges stuck particles.

Paint Stripping

Soda’s abrasiveness, combined with pressure, gently strips paint off of surfaces. It’s effective enough that you won’t need extra tools or equipment, such as sanders or grinders. What’s more, sodium bicarbonate’s gentle nature won’t damage or warp underlying surfaces.

For those reasons, soda blasting is ideal for automotive restoration projects. Sodium bicarbonate allows for the safe removal of paint on vehicle panels and bodies. Soda blasting, when done correctly, won’t damage the surface beneath the paint.

All those characteristics also make soda blasting great for graffiti removal.

Cleaning and Stripping Sensitive Materials

Soda blasting is also safe for cleaning aluminum, chrome, glass, metal, and rubber. Sodium bicarbonate is also an ideal cleaner and stripper for fiberglass. By contrast, harder abrasive agents, such as sand, can dent, distort, or warp these surfaces.

Degreasing and Rust Removal

Sodium bicarbonate’s slight abrasiveness makes it efficient for eliminating grease and oil. It can even remove burnt residues, grime, and carbon build-up. This is why soda blasting media has also found use in motorcycle restorations.

Sodium bicarbonate also acts as a mild abrasive that scrapes rust off as it dissolves. It also prevents new rust from forming, as it creates a protective barrier over the surface. With soda blasting, you have more time between surface preparation and coating.

Smoke and Soot Remediation

Baking soda is such an effective deodorizer that it can even decrease the strong odors of kimchi. It can do this as it reacts with both acid and alkaline molecules. From there, it turns the malodorous molecules into neutral-smelling salts.

This smell-neutralizing effect makes soda effective for removing smoky smells and cleaning soot. In fact, remediation companies use soda blasting to clean and deodorize charred surfaces.

Lead Paint Removal

As many as one in four US homes built between 1960 and 1977 may still contain lead-based paint. This goes up to a staggering 69% for homes built from 1940 to 1959 and 87% for those erected prior to 1940.

Now, keep in mind that eight in 10 US homes are at least two decades old. Of these houses, 38% have been around before 1970. This is why experts say that lead-based paint is still in millions of homes around the country.

Exposure to lead paint particles is a health and safety threat as it can cause lead toxicity. Lead poisoning often occurs over many years, but it can also occur within just months. It can cause severe and long-term mental and physical impairment.

Lead toxicity can cause abdominal, sleep, blood pressure, and kidney problems. It can also cause headaches, fatigue, appetite loss, and memory issues. In children, it can result in impaired development, behavioral issues, and hearing problems.

Wet blasting techniques, in which you can use soda, are some of the safest methods for lead paint removal. That’s because the use of slurry, which is wet, helps reduce the rebound rate of particles. The liquid mixture traps not only the abrasive particles but also the removed paint.

The water also weighs down the particles, so they flow down with the water instead of bouncing. Moreover, the use of slurry helps cut back the amount of dust produced by the blasting activity.

Mold Cleanup

Prompt mold clean up is crucial as the spores they emit can trigger allergies and asthma. In the US alone, one in 10 people have mold allergies. What’s more, there are over 80 types of mold associated with lung, nose, and throat problems.

Molds can grow in as little as 24 hours if they have access to oxygen, water, and food. Food, in this case, is an organic material, such as wood or paper. So long as these three things are present, molds can keep growing and eating away at materials.

Fortunately, soda blasting is also very effective for cleaning and removing mold growths. For starters, sodium bicarbonate has antifungal and antibiofilm effects. These properties help make it effective for killing active mold patches and spores.

Of course, soda also scrubs clinging mold off of surfaces. Like with smoke and soot remediation, soda blasting also helps get rid of moldy smells.

Soda blasting is the preferred method for mold clean up as it doesn’t damage fragile surfaces. You can use it to treat mold-ridden wood, PVC, ductwork, or even wiring components.

What Are the Advantages of Using Sodium Bicarbonate as a Blasting Agent?

The soda used in soda blasting is safer than sand and is also easier to clean. Neither does it contain heavy metals or emit dangerous vapors. All these make soda an attractive (and less risky) abrasive agent.

Doesn’t Contain Crystalline Silica

Crystalline silica, also known as quartz, is a common mineral found in sand, granite, and rock. Respirable crystalline silica (RCS) measures less than 10 µ in diameter. It’s these micro-tiny grains that put 2.3 million people in the US at risk of silica-related diseases.

Of the people exposed to RCS, many are those whose work involves abrasive blasting. That’s because sand remains one of the most common forms of blasting media.

RCS is a huge health threat as it can cause an irreversible lung disease called “silicosis.” Silicosis occurs over years of inhaling RCS dust, which causes permanent lung scarring. This leads to inflammation, and eventually, a decrease in lung capacity and functions.

Moreover, RCS is a mineral regarded as a human lung carcinogen. This means that it can cause cancers of the lung.

However, researchers also say that it may raise one’s risks of other cancers. RCS exposure may also be a risk factor in the development of esophageal, stomach, and skin cancers.

RCS exposure also increases a person’s risk of chronic obstructive pulmonary disease (COPD). COPD is a group of lung disorders that can result in breathing difficulties. These include emphysema and chronic bronchitis, both of which are progressive conditions.

There is no RCS in the sodium bicarbonate media used in soda blasting techniques. This is one of the reasons that soda blasting can be much less risky than sandblasting.

Doesn’t Contain Toxic Heavy Metals

Sandblasting media, such as metal slags, can contain trace levels of heavy metals. Some of these include arsenic, beryllium, and cadmium. All three are human carcinogens that can primarily cause lung and skin cancer.

Sodium bicarbonate doesn’t contain any of these heavy metals.

Doesn’t Emit Hazardous Vapors

In many cases, surface cleaning and preparation require the use of solvents. These chemicals remove surface contaminants that can impair finishing products, such as paint. The most common solvents used are acetone, isopropyl alcohol, and methyl ethyl ketone.

As effective as these solvents are, they still emit vapors that can cause health effects. For instance, inhaling high levels of solvent vapors can harm the nervous system. This can also cause confusion, dizziness, headaches, nausea, and even unconsciousness.

Soda blasting doesn’t create the same hazards, but note that the dry technique creates a lot of dust. Inhaling large amounts of sodium bicarbonate can also lead to coughing and sneezing. You can avoid these by donning proper protective equipment, such as dust masks.

A More Eco-Conscious Blasting Medium

Soda blasting is often enough to clean and prep surfaces without the need for other solvents. This alone makes it an eco-friendlier option since you may no longer have to use toxic chemicals. The EPA itself says that sodium bicarbonate has a minimal environmental impact.

Soda blasting media is also easier to clean, thanks to its water solubility. You can then use a filter to separate the liquid from the solids removed by the blasting process. So long as the liquid waste doesn’t have toxic chemicals, you may be able to use direct disposal methods.

By contrast, non-soluble blasting media like sand requires specialized recovery and clean-up methods. Otherwise, the heavy metals they contain may contaminate land and water formations.

Soda Blasting Can Be a Safer Abrasive Blasting Method

There you have it, all the facts you need to know about sodium bicarbonate as soda blasting media. Soda is a gentler, milder abrasive, making it ideal for sensitive surfaces. It also has added deodorizing benefits, which make it an even better choice than sand.

Most importantly, soda blasting isn’t as risky as sandblasting. Plus, you can use it in both dry and wet blasting, so it’s versatile and cost-effective.

If you’re interested in soda and wet blasting, we here at Vapor Honing Technologies can help! Feel free to get in touch with us to inquire about free application testing.