Excellent Surface Preparation

When it comes to cleaning and surface preparation, wet soda blasting is one of the most effective and environmentally friendly methods available. This technique combines the power of abrasive blasting with the gentleness of water, offering several advantages over traditional dry blasting methods. If you’re looking for an effective way to clean delicate parts, such as carburetors, or remove stubborn coatings, wet soda blasting with baking soda is a great choice.

What is Wet Soda Blasting?

Wet soda blasting is a process where baking soda (also known as sodium bicarbonate) is used as an abrasive, combined with water and compressed air to clean surfaces. Unlike dry blasting, where the soda is used in its dry form, wet blasting adds water to the mix, which significantly reduces airborne particles and prevents the accumulation of residual material on the surface being cleaned.

Key Benefits of Wet Soda Blasting

- No Residuals: One of the standout advantages of using wet soda blasting is that it doesn’t leave any residual on the surface. Traditional dry blasting, especially with abrasives like sand, can leave behind debris and residue that must be cleaned off, potentially affecting the finish and functionality of the part. Since baking soda is water-soluble, it dissolves easily during the wet blasting process, ensuring that no abrasive particles remain to interfere with post-cleaning processes or cause damage.

- Gentle Cleaning: Wet soda blasting is particularly effective on delicate parts that need cleaning without causing damage. Carburetors, for example, are intricate and can be sensitive to abrasive damage. The gentle nature of baking soda as an abrasive ensures that parts like these can be cleaned thoroughly without altering their structure or surface. The water also helps to keep the blasting process cool, reducing the risk of heat-related damage.

- Environmentally Friendly: Since baking soda is non-toxic and biodegradable, wet soda blasting is an environmentally friendly option. Great for companies concerned with their carbon footprint. Additionally, the water used in the process helps to trap and contain any dust or contaminants, preventing them from being released into the environment.

- Surface Preparation: Wet soda blasting is highly effective at cleaning and preparing surfaces for coatings, painting, or further processing. The process gently removes contaminants, grease, dirt, and old coatings, leaving a clean, slightly roughened surface that enhances the adhesion of subsequent treatments. This makes it particularly valuable in industries like automotive, aerospace, and manufacturing, where high-quality finishes are essential.

- Reduced Dust and Mess: In contrast to dry blasting, wet soda blasting dramatically reduces the amount of airborne dust. This not only helps to create a safer and cleaner working environment but also eliminates the need for extensive cleanup afterward. The water in the mixture captures the dust, allowing it to be safely contained, preventing it from spreading around your workspace.

- Application: Whether you’re cleaning rust, old paint, or carbon buildup, wet soda blasting offers a versatile solution for a wide range of applications. It’s used extensively in industries such as automotive, marine, and aerospace, but it’s also useful for cleaning industrial equipment, removing graffiti, or restoring historical buildings. Its adaptability and gentle cleaning power make it an indispensable tool in many industries.

A Note on Supersaturation

When using wet soda blasting, it’s important to supersaturate the water with baking soda. This ensures that the abrasive is properly carried through the system and efficiently impacts the surface without excessive clogging or loss of effectiveness. Supersaturating the water creates a consistent flow of soda particles that maximizes the cleaning power of the process, while also preventing uneven distribution and enhancing the overall cleaning efficiency.

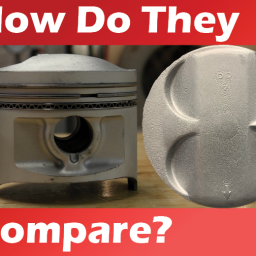

See Wet Soda Blasting in Action

Want to see wet soda blasting in action? Watch our video below, where one of our skilled technicians is demonstrating the soda blasting process on a carburetor. You’ll get a firsthand look at how effective and gentle this cleaning method is.

About Vapor Honing Technologies

Vapor Honing Technologies builds industry-leading wet blasting machines, delivering surface finishes as refined as a Lamborghini’s performance in the automotive world. By combining water, air, and abrasive, our machines simultaneously clean and polish, achieving surface roughness values unachievable by similar processes. This flow-based method is safe for delicate materials and saves both time and money. Proudly manufactured in Lincolnton, NC, our machines are built for durability and backed by a lifetime warranty on non-consumable components. Plus, our trade-up program lets you upgrade without losing value. Customer satisfaction drives our success, and we’re here to help.

Contact a member of our sales team today at (828)202-5563. We are here to answer all your questions, as you investigate the surface finishing industry. Have a nice day!