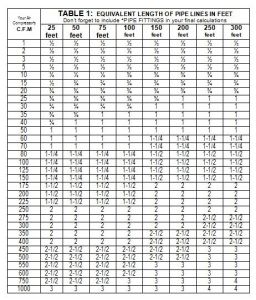

What CFM and PSI do I need?

- This is all adjustable from 10 CFM up to 18 CFM by the nozzle ID size we send to you.

- We have nozzles from 6mm– 12mm ID

- Normal Operating PSI is 80– 100 PSI very rarely will you deviate from this range.

- Most air compressors in good condition generate 3 CFM per motor horsepower.

What slurry pumping system do you use?

- Industry proven high volume submersible systems with polyurethane impellers.

- Impellers are abrasion resistant to withstand the harshest conditions.

- Our heavy industrial pumps come backed with a two year warranty.

- We have yet to have any of our pumping systems fail in the most extreme environments

How to chose the correct abrasive for your job.

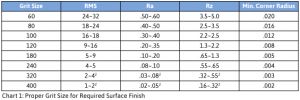

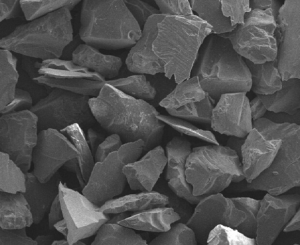

- Finishes are determined by the edge profile of the abrasive.

- Round circular beads such as glass bead and ceramic bead will roll across the substrate creating a lapping or finishing effect.

- Other abrasives such as aluminum oxide, silicon carbide, crushed glass, and ceramic grit have sharp angular edges which will flow across the surface scratching and etching the surface which will not leave the surface shiny but matte and ready for coatings.

| Per 50lbs. | |

| Glass Beads | $45.00 |

| Ceramic Beads | $500.00 |

| Aluminum Oxide | $75.00 |

| Silicon Carbide | $122.00 |

| Crushed Glass | $30.00 |

| Plastic Grit |

$65.00 |

Abrasive Cost Per lb.

Abrasive Applications

| Surface Finishing | Coating Prep | Wet Shot Peening | De Burring | |

| Glass Beads | Yes | Yes | ||

| Ceramic Beads | Yes | Yes | Yes | |

| Aluminum Oxide | Yes | Yes | ||

| Silicon Carbide | Yes | Yes | ||

| Crushed Glass | Yes | Yes | ||

| Plastic Grit | Yes | Yes |