Vapor Honing Cabinet for Sale: Here’s Why You Need One

Have you considered a vapor honing cabinet in the past but didn’t know enough about them to make a decision. Or did you think a vapor honing cabinet was too expensive for your workshop? In this article you will see how a vapor honing cabinet from Vapor Honing Technologies can help.

From hubcaps to carburetors, vapor honing is a convenient way to clean dirty parts. It’s the ideal blasting solution whether you work on cars, motorcycles, boats, or heavy machinery.

And that’s just the beginning. With DIY vapor honing, you can safely clean gaskets, nuts and bolts, and tools. Even delicate materials, like plastics and wooden objects, can be like new again.

Whether you’re starting an auto body shop or tinkering at home, a vapor honing cabinet could be your new best friend. If you aren’t convinced yet, keep reading, because you’re about to be.

What Is Vapor Honing?

Vapor honing is a type of abrasive blasting. Abrasive blasting involves spraying fine particles at high pressures, such as sand or crushed glass, to clean and prepare hard surfaces.

There are several different materials used for blasting, called media. Some of these media are hard, for cleaning stubborn buildup off of durable objects. Other media are soft, for more delicate tasks.

You may have heard people refer to abrasive blasting as sandblasting, which has become a catch-all term to describe the process. However, people rarely use sand anymore, as it breaks down into a powder upon impact. This makes it less effective at cleaning surfaces, and less suitable for abrasive blasting as a result.

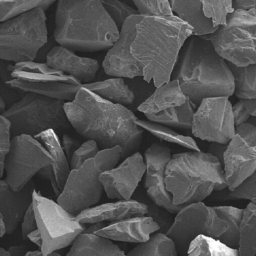

Hard blasting media include aluminum oxide, silicon carbide, glass beads, and steel shot. Soft abrasives include things like plastic beads and walnut shells. Depending on the media used, you can clean rust, old paint, and contaminants of all kinds off of metal objects.

Because sandblasting involves spraying hard particles at very high pressures, users must wear special protective gear. Sometimes sandblasting is done in a specially prepared room, called a blast room.

Usually sandblasting will take place inside a metal cabinet, with heavy-duty gloves fastened on one side, allowing the user to handle the object being cleaned. This only works for cleaning relatively small parts, but it’s sufficient for most tasks.

While normal abrasive blasting has many applications, it also has several downsides. That’s where wet blasting, or vapor honing, comes in.

Vapor Honing vs. Sandblasting

As you’ve probably picked up on, sandblasting is a heavy-duty surface preparation process. Even when using soft media, it is highly abrasive and can damage certain surfaces. You can only clean very durable surfaces with this method, and even then you have to be careful.

Vapor honing, on the other hand, is a non-aggressive surface preparation technique. It’s specifically designed for surfaces with finer finishes, and it’s more versatile than regular sandblasting.

While sandblasting uses pressurized air to spray dry particles, vapor honing combines a thin stream of high-pressured water with fine blasting media. It’s somewhat like a pressure washer, only it uses an air compressor and is much more powerful.

The water prevents sparks and protects the surface that’s being cleaned. Meanwhile, the blasting media removes any dirt, rust, corrosion, or other contaminants.

Sandblasting creates the same type of finish you would get from hand sanding, just more evenly and efficiently. Besides being very aggressive, it leaves a rough, coarse finish on the surface. This rough finish is essentially primed to pick up more dirt in the future, as contaminants will stick to rough surfaces.

Instead of leaving a rough finish, vapor honing smooths the surfaces. Not only does this perfectly clean surfaces, but it also makes them more resistant to collecting dirt and grime in the future.

Dust Comparison

Another common problem with sandblasting is that the media used is often highly toxic. Chemicals are often used in the sandblasting process, and this can be bad for the environment as well as the user. Sandblasting also creates lots of dust, which can cause respiratory problems.

Since it uses water as its primary material, vapor honing is very environmentally friendly by comparison. It also doesn’t require the use of toxic media or dangerous chemicals. And because vapor blasting is wet by definition, excessive dust is never an issue.

It’s not hard to see why a vapor honing cabinet would be more useful for most tasks than a sandblasting system. But there’s one more abrasive blasting method we need to compare: soda blasting.

Vapor Honing vs. Soda Blasting

Along with sandblasting, soda blasting is one of the primary ways to clean or prepare surfaces for industrial coatings. Soda blasting is similar to sandblasting in terms of its processes and equipment. But when it comes to materials and applications, they’re very different.

The main difference between soda blasting and sandblasting is the media. Sandblasting typically uses coarse, aggressive media to attack stubborn grime and contagions. Soda blasting uses sodium bicarbonate or household baking soda.

Naturally, baking soda is relatively gentle on soft surfaces, even at very high air pressures. Because of this, soda blasting is usually only for cleaning purposes. However, you can also use it for coating preparation and to remove rust.

While sandblasting is used almost exclusively on metal, soda blasting is particularly effective on softer surfaces. This includes things like wood, chrome, and plastic. It is often used for automotive restoration as well.

One considerable advantage soda blasting has over sandblasting is its nontoxic media. Again, sandblasting often involves the use of chemicals, but baking soda is perfectly safe. Humans can even ingest baking soda safely. This makes soda blasting a more environmentally friendly option.

However, for many applications, soda blasting is far from the ideal option. Although soda blasting and vapor honing may seem to perform the same functions, they still have some critical differences.

Dust Comparison

One major concern with soda blasting is the dust factor. Since you’re spraying high-pressured powder instead of hard media, airborne dust is an even bigger problem than it is with sandblasting.

While it’s probably better to breathe in baking soda than abrasive sandblasting media, it isn’t perfectly safe. Because of this, proper protective gear is a must to avoid painful respiratory problems.

Another drawback for soda blasting is that it can’t use the same high pressures as sandblasting and vapor honing. While sandblasting and vapor honing can both exceed pressures of 120psi, soda blasting reaches its limit at around 20psi of force.

Ultimately, vapor honing is superior to soda blasting simply because it’s more flexible. It combines the high-pressure firmness of sandblasting with the gentle versatility of soda blasting.

Vapor honing is not just the middle ground between two extremes for most needs, it’s ideal.

Why You Need a Vapor Honing Cabinet

Since its introduction in the United States not long ago, vapor honing has become increasingly popular. In fact, an episode of Jay Leno’s Garage once featured a vapor honing cabinet from Vapor Honing Technologies.

You can already see why vapor honing is a superior alternative to sandblasting and soda blasting. Still not impress yet, here are even more reasons a vapor honing cabinet belongs in your workshop.

Finer Finish

Perhaps the greatest advantage of vapor honing over sandblasting is the smooth, fine finish it produces.

Although vapor honing uses abrasive media just like sandblasting does, the water involved always flushes it out. This means there’s no impregnation of abrasive on the surface. The result is a cleaner, smoother surface with more shine.

Besides helping flush away the abrasive, vapor honing allows for use of much finer media. This helps the abrasive to get into tight cracks, so everything is pristine.

Gentler Approach

In traditional sandblasting, you literally blow particles of sand or other media against a surface. Think of it like tiny bullets shooting into objects, ricocheting off of metal. Obviously, that’s going to leave a mark on many softer materials.

In vapor honing, the water acts as a cushion between the abrasive and the surface. It acts as a dampener, allowing the media to do its work without damaging the surface in any way.

When dry abrasive hits a hard surface, it bounces off and breaks into finer particles. This is why sand will turn into powder when it’s being blast. But with the addition of water, the abrasive doesn’t break apart as easily. This makes it even more effective.

And as if that wasn’t enough, the water in vapor honing keeps the entire mixture together, preventing dust. When you consider all these benefits together, you can see why a vapor honing cabinet is the obvious choice.

Multiple Media Abrasives Available

When you use vapor honing, you aren’t limited to a single type of abrasive media, like you would be with soda blasting. In fact, you can combine practically any type of blast media with water.

For wet blasting inside a honing cabinet, people will often use a mix of sodium bicarbonate and fine glass beads. Pumice, steel shot, steel grit, copper slag, and even crushed glass are also viable options.

The media you choose will depend on the application you need it for. The important thing is, you have a wide range of options available to you with vapor honing.

Versatile Applications

You can use vapor blasting in so many ways it’s impossible to know where to begin. Dozens of industries uses it, from auto repair to construction.

Vapor honing is a logical choice for cleaning rust, grease, factory coatings, and other contaminants from auto and motorcycle parts. Professionals who restore old bikes and vehicles will use vapor honing to make antique parts look brand new.

It’s only natural that vapor honing would appeal to auto restorers. It gives aluminum, chrome, and steel surfaces a beautiful satin-like finish.

Vapor blasting is the ideal choice in industries where multiple fire hazards exist. Sandblasting can create sparks as dry media slams into surfaces. But for dustless vapor honing, this is a non-issue.

Thanks to the water holding the media together, there’s practically no risk of fire.

Unlike sandblasting, you can use vapor honing on more than just metal surfaces. Because of this, it’s widely used for historical and antique restoration. This can include wood restoration, graffiti removal, and cleaning up fire damage.

You will also find vapor honing in aerospace and engineering facilities. It’s highly effective for removing carbon deposits, old paint, oxidation, and many other contaminants familiar in engineering.

Sometimes construction regulations have rules against airborne dust, particularly in residential areas. Once again, vapor honing comes to the rescue with its unique dustless operation.

There are countless more applications for vapor honing, some of which probably have yet to be discover. Vapor honing is relatively new in the United States. When you purchase a cabinet of your own, you become a part of engineering history.

A Vapor Honing Cabinet Could Be Your Greatest Investment

From its dustless operation to its flexibility, you can now see why you might need a vapor honing cabinet yourself.

You could supplement your workshop or go into business offering vapor honing services. Either way, Vapor Honing Technologies accessories and cabinets are always a fantastic investment.

Maybe you want to go all-out with the Vapor Hone 4000, or perhaps a basic model meets your needs best. Whichever you choose, place your order with Vapor Honing Technologies today.