-

100% built in the USA

-

American tech support Monday – Friday

-

Built to last and work non-stop

-

Fully welded hopper to prevent spillage

-

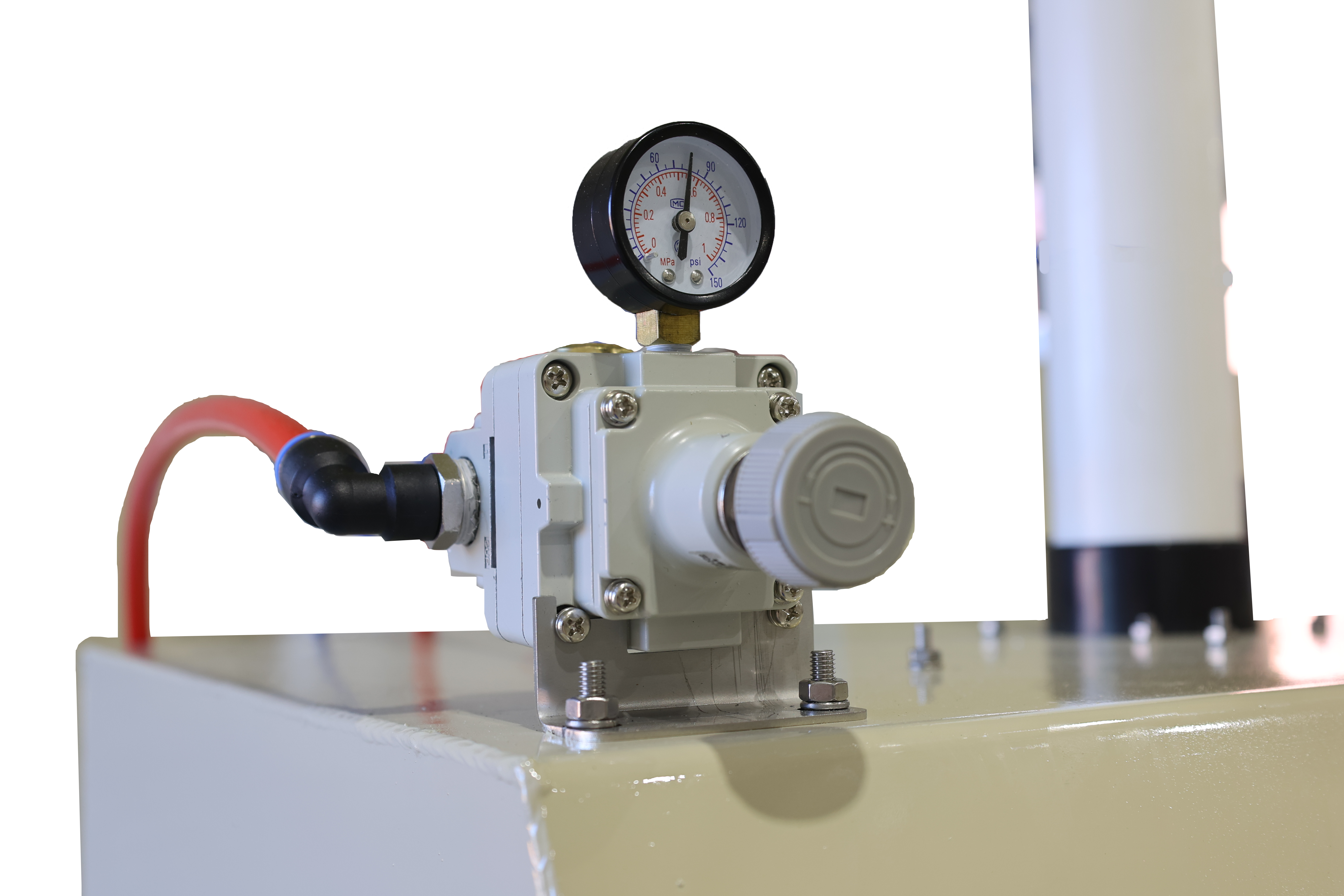

Includes precision regulator

-

GFCI plug is standard

-

Machine exterior is painted Desert Tan

-

Constructed of robust mild steel

-

Powder coated for longevity

-

Large loading doors on both sides

-

Dual operation upgrade available

-

Foot pedal operated for ease of use

-

Large LED light bars for excellent visibility

| Internal Working Dimension | 60″ W x 48″ D x 38″ H |

| Power | 110V Single Phase |

| Abrasives Amount | 42 lbs. |

| Abrasive Delivery | Suction or Pressure Pot |

| Gun Tips | Boron Carbide |

| Collection System | Reclamation System |

| CFM | 20-30 Per Blast Gun |

| PSI | 60-100 PSI |

| Assembly | No Assembly Required |

Great Add-Ons for Your VH4000 Dry Blast

Dust Collector

A dust collector is designed to remove airborne dust and fine particles generated during the sandblasting process. Sandblasting produces a significant amount of dust from the abrasive media and the material being removed from the surface. Using a dust collector helps maintain a cleaner work environment by reducing airborne dust levels. It also minimizes the risk of operators inhaling harmful particles, improves visibility inside the blasting cabinet, and prevents dust from settling on surrounding surfaces.

Reclamation System

The reclamation system is focused on recycling and reusing the abrasive media used in the sandblasting process. Its primary function is to collect, separate, and reintroduce the reusable abrasive media back into the blasting operation. This helps reduce material costs by recycling abrasive media, maintains consistent blasting performance, and minimizes waste disposal requirements.

Machine works amazing

It has increased revenue by 50% on used parts and components

We have the weekend warrior machine

I would recommend this for anyone wanting to renew anything corroded or rusted to absolutely renew

Thank you Vapor Hone, JB

It has increased revenue by 50% on used parts and components

We have the weekend warrior machine

I would recommend this for anyone wanting to renew anything corroded or rusted to absolutely renew

Thank you Vapor Hone, JB

It is not often that you deal with a company that checks of all the boxes.

Great product, fantastic customer service, quick turnaround and constant upgrades to the product line.

Since the purchase of my machine many years back, it has been the absolute best purchase I have ever made as an addition to my motorcycle restoration and rebuild shop. The quality construction and high caliber components totally changed the way my motorcycles came out. I noticed and so did my customers!

Over the years, I have needed some spare parts and consumables. Anytime I placed and order my requests were answered very quickly. Communication was never an issue and all orders were shipped out promptly and tracking info was always provided.

My machine has been used extensively over the years, and with Vapor Honing Technologies constant innovation, it has allowed me to retrofit my machine with some of the newest upgrades.

It continues to make my machine the most useful tool in my shop.

Overall, the buying experience and the ownership experience has made this a game changer for the overall quality of my restorations.

I consider it the best tool purchase I have ever made!

David Crandall

Birmingham, Alabama

Great product, fantastic customer service, quick turnaround and constant upgrades to the product line.

Since the purchase of my machine many years back, it has been the absolute best purchase I have ever made as an addition to my motorcycle restoration and rebuild shop. The quality construction and high caliber components totally changed the way my motorcycles came out. I noticed and so did my customers!

Over the years, I have needed some spare parts and consumables. Anytime I placed and order my requests were answered very quickly. Communication was never an issue and all orders were shipped out promptly and tracking info was always provided.

My machine has been used extensively over the years, and with Vapor Honing Technologies constant innovation, it has allowed me to retrofit my machine with some of the newest upgrades.

It continues to make my machine the most useful tool in my shop.

Overall, the buying experience and the ownership experience has made this a game changer for the overall quality of my restorations.

I consider it the best tool purchase I have ever made!

David Crandall

Birmingham, Alabama

Amazing machine, we use it on re furnishing cylinder heads to cylinder blocks and every engine part part in between. Anything that is old and corroded, it makes them look like they are brand new again!

I purchased my Vh800 Closed Loop cabinet a couple years ago and I love it. Customer service was excellent and setup of the machine was easy. I have had zero issues with my cabinet and it provides phenomenal results! Would highly recommend.

Bought a VH800 Base, great system, easy to set up and much cleaner than dry blasting. Very helpful customer support with quick responses. Ask for Rick, genuinely nice guy. Thanks from Forge Automation.

I'd like to remain professional in my response, but I see this mess everyday as a constant reminder. Do your research before buying a vapor blasting machine.

Sand Blasting FAQs

- What is sandblasting?

- What are the primary applications of sandblasting?

- Is sand always used in sandblasting?

- Is sandblasting safe for operators and the environment?

- Can sandblasting be used on all surfaces?

- Sandblasting is a surface preparation technique used to remove paint, rust, corrosion, and other contaminants from various surfaces. It involves propelling abrasive materials, such as sand, at high speeds using compressed air or other methods to clean or prepare a surface for further treatment, like painting or coating.

- Sandblasting is commonly used in various industries, including automotive, construction, manufacturing, and shipbuilding. Some common applications include removing old paint or coatings, cleaning metal and concrete surfaces, etching glass or stone, and preparing surfaces for painting or welding.

- Sand was historically a common abrasive material in sandblasting. Today, safety and environmental concerns have led to the use of alternative abrasive materials like garnet, aluminum oxide, glass beads, and plastic media. The choice of abrasive material depends on the specific application and the surface being treated.

- Sandblasting can be hazardous if proper safety precautions are not followed. Operators should wear personal protective equipment, such as respirators, goggles, and protective clothing, to prevent exposure to airborne abrasive particles. Additionally, proper containment and dust collection systems are essential to minimize environmental impact and protect workers from harmful dust and contaminants.

- Sandblasting may not be suitable for all surfaces, as it can be too aggressive and potentially damage delicate materials like wood or thin metal. The choice of abrasive material, blasting pressure, and technique must be carefully selected based on the surface type and the desired outcome. In some cases, alternative methods like Vapor Honing, soda blasting, or dry ice blasting may be more appropriate for sensitive materials.