-

Our HB900 is backed up by the industry’s best LIFETIME WARRANTY

-

100% built in the USA

-

American tech support Monday – Friday

-

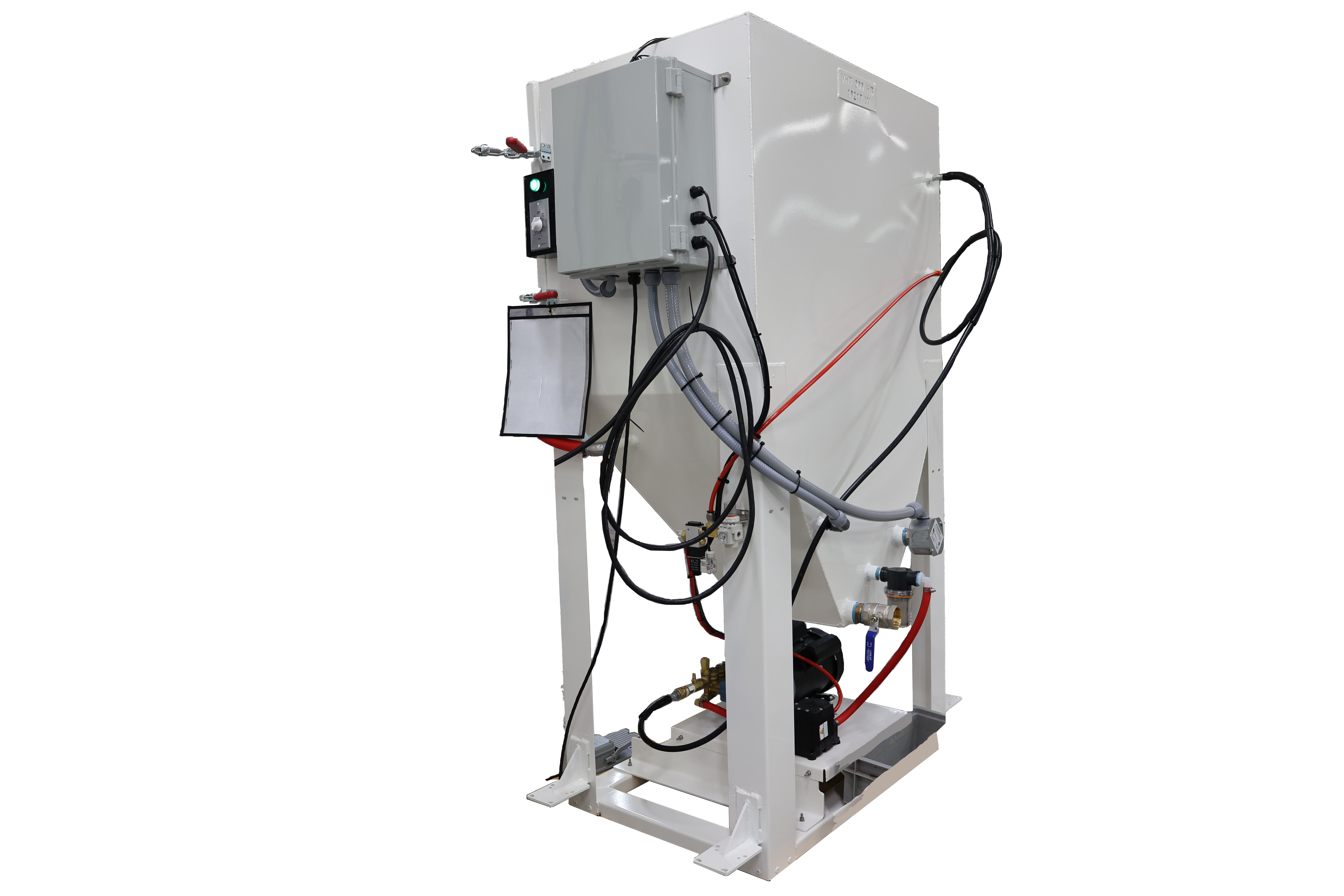

Constructed of carbon steel

-

The HB900 is built to last

-

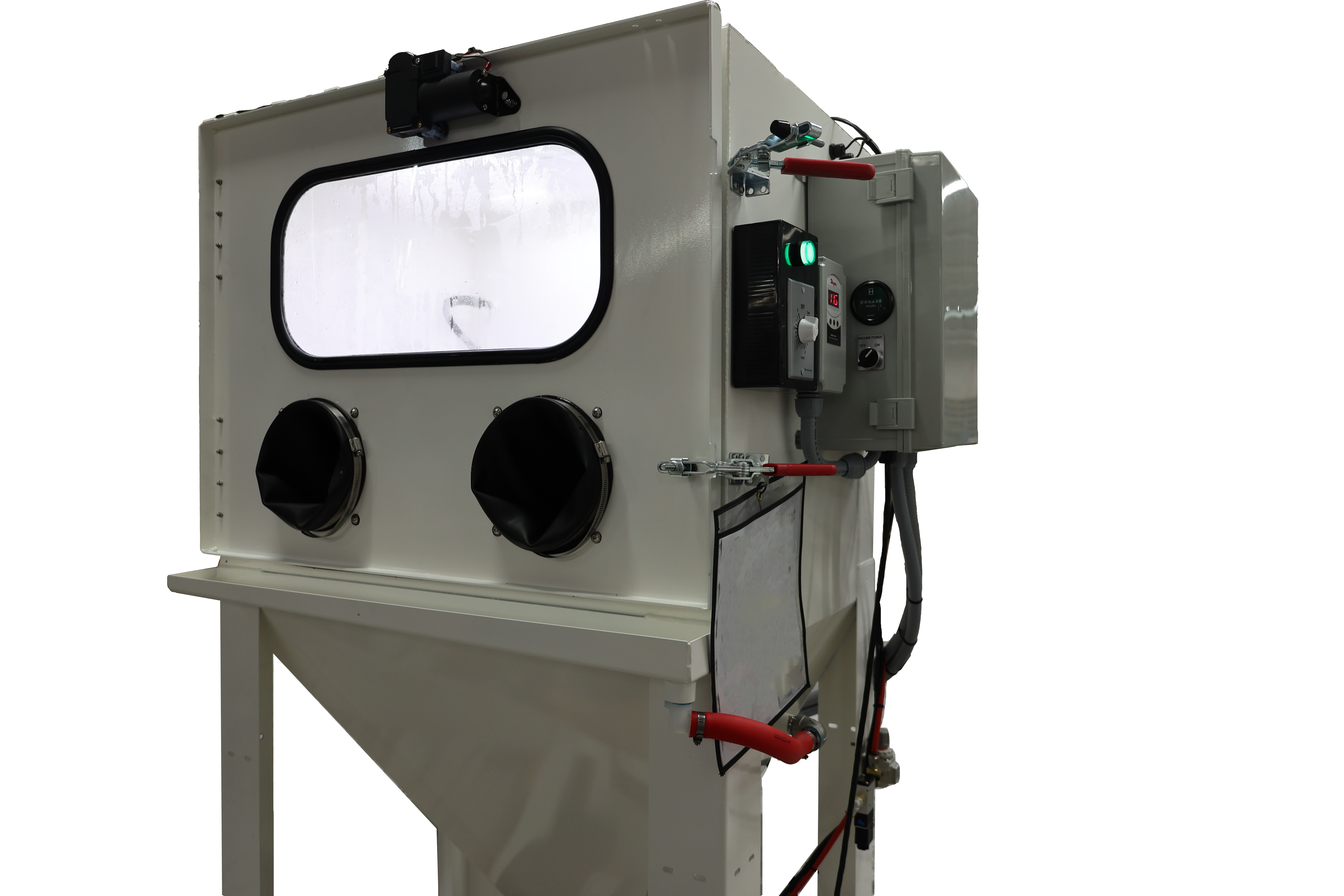

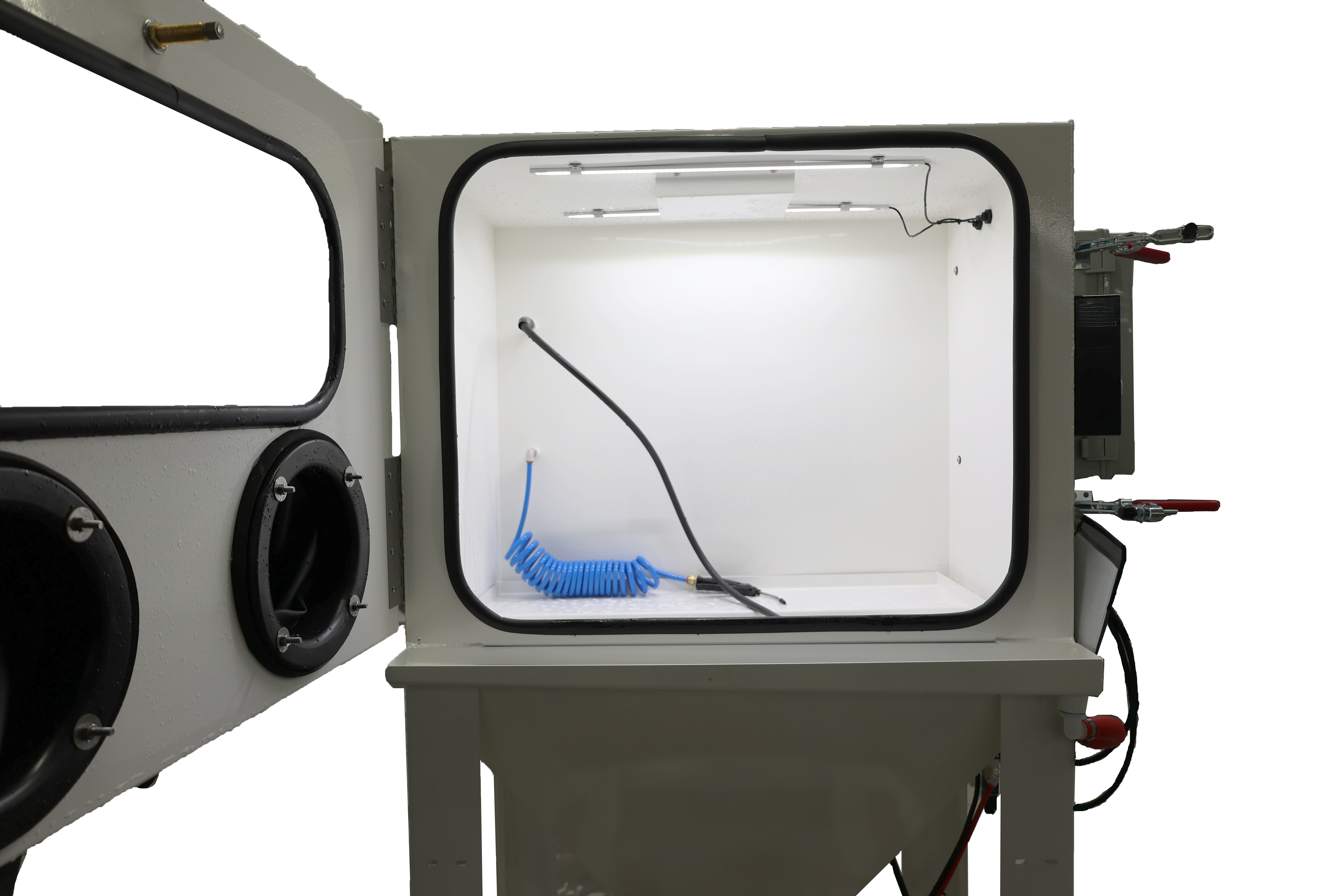

2 (2′) LED light bar for better visibility

-

Front-load door

-

Wiper included

-

Foot pedal control

-

Upgrade option w/o depreciation

-

Adjustable Spray Nozzle

-

Dryer hose inside

-

The HB900 combines the amazing cleaning capability of the Hydro Blast with the great cabinet style the 900 series offers.

-

A heater comes standard with the HB900, which aids in the removal of oil, grease, and grime.

-

Machine exterior is painted Gunmetal Gray

-

The HB900 can be used with an aqueous based detergent to aid in grease and grime removal.

| Internal Working Dimension | 36″ W x 24″ D x 30″ H |

| Power | 220V Single Phase |

| Abrasives Amount | NO ABRASIVE |

| Water Amount | 25 Gallons |

| Pump | High Volume Pressure Pump |

| CFM | 15 CFM |

| PSI | 1200 PSI at The Gun |

| Assembly | No Assembly Required |

Company Reviews

A happy business owner her. Marshall Plumb

It has increased revenue by 50% on used parts and components

We have the weekend warrior machine

I would recommend this for anyone wanting to renew anything corroded or rusted to absolutely renew

Thank you Vapor Hone, JB

Great product, fantastic customer service, quick turnaround and constant upgrades to the product line.

Since the purchase of my machine many years back, it has been the absolute best purchase I have ever made as an addition to my motorcycle restoration and rebuild shop. The quality construction and high caliber components totally changed the way my motorcycles came out. I noticed and so did my customers!

Over the years, I have needed some spare parts and consumables. Anytime I placed and order my requests were answered very quickly. Communication was never an issue and all orders were shipped out promptly and tracking info was always provided.

My machine has been used extensively over the years, and with Vapor Honing Technologies constant innovation, it has allowed me to retrofit my machine with some of the newest upgrades.

It continues to make my machine the most useful tool in my shop.

Overall, the buying experience and the ownership experience has made this a game changer for the overall quality of my restorations.

I consider it the best tool purchase I have ever made!

David Crandall

Birmingham, Alabama

Hydro Blasting Questions

1. What’s the regular maintenance on the Hydro Blast machine?

2. How often do you need to change the water and detergent?

3. Can the Hydro Blast be used for post cleaning after vapor honing?

4. Will a Hydro Blast provide the same results as a Vapor Honing machine?

1. Refreshing and changing the water, as well as cleaning the under floor filters, are the regular maintenance tasks associated with a Hydro Blast.

2. If the water in your machine becomes dirty or begins to smell, it is time to be refreshed. Typically the water and detergent last around a month in the VH900 Hydro Blast.

3. Absoloutley! The high pressure heated water helps dislodge abrasive and other possible parts. Leaving you with the cleanest possible part after Vapor Honing.

4. The VH900 Hydro Blast cannot remove contaminates locked into the substrate of the part due to the lack of an aggregate in the blasting liquid. This is in contrast to Vapor Honing, which does deploy a slurry to effectively strip and clean parts.