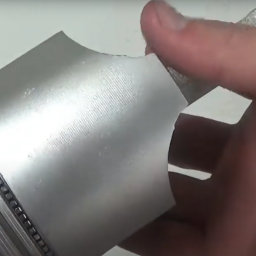

Weld Cleaning Stainless Steel

Have you been welding and finishing stainless steel trying to find an alternative to cleaning the welds? Weld cleaning stainless steel can be very challenging at times depending on the look your trying to achieve. We have been welding stainless steel for many years and have used many methods in the past some of them are below.

- Hand buffing with scotch brite pads

- Passivization compounds

- Tig brush cleaning

- Multi stage/grit sanding

- Dry abrasive blasting

Better to Vapor Blast

Each of the above, we have found their place but not all are equal or even practical at times. However, some methods do not work and some are just downright harmful to the operator and environment. One method we’ve found when weld cleaning stainless steel is to abrasive blast using a vapor honing system. If you have parts that can fit within an abrasive blast cabinet then we encourage you to try the process and see the results for yourself.

If you have larger items that will not fit within a blasting cabinet then we have larger platform blast system designed specifically to blast larger items. In fact, the two systems discussed above are both recirculating systems. Meaning the abrasive and water is reused lowering your cost of operation and weld cleaning.

What we’ve found when weld cleaning stainless steel parts in the vapor honing system is that there is minimal disturbance to the surrounding areas around the welds. Also, if you need to blend in light scratches this is also an option with the vapor honing system. The last and final point and finding is that if a consistent finish is needed across the entire part this is also achievable as well using the vapor honing system being that the wet slurry travels more consistently across the surface of the part.