What Is Vapor Honing: The Ultimate Guide

Vapor honing is a great way to refinish surfaces without the drawbacks of sandblasting.

You might hear people refer to vapor honing using a variety of names. For instance, someone might call it slurry blasting.

Alternatively, you may hear someone mention liquid abrasive blasting or liquid honing. You might even hear someone use the terms wet honing or wet etching. Either way, all these terms referred to the same highly effective process.

Vapor honing involves mixing abrasive materials with water. Compared to sandblasting, the process is much less erosive to surfaces.

For the ultimate guide to vapor honing, keep reading.

An Emerging Trend in Surface Refinishing

Over the last decade, there’s been a major transformation in the field of abrasive blasting. A growing number of operators are choosing vapor honing over sandblasting.

When comparing the two practices, people will usually refer to vapor honing as wet blasting. Alternatively, they’ll refer to sandblasting as dry blasting.

Reluctantly, you may have heard talk of both wet blasting and dry blasting practices. However, the two procedures are completely different.

Some operators spend hours operating blasting equipment. If this scenario sounds familiar, you’ll easily see the benefits of wet blasting versus dry blasting practices.

For example, wet blasting produces little to no dust. Also, wet blasting operators have increased work area visibility.

Furthermore, wet blasting equipment is much quieter compared to sandblasting equipment. For this reason, long-term operators of wet blasting equipment do not suffer hearing loss as much as dry blasting operators.

There are differences in the wet blasting and dry blasting processes. It’s important to understand how the processes vary.

These differences are the reason why a growing number of operators are choosing vapor honing over sandblasting. With the right information, it’s easier to see why you should make the switch.

What Is Vapor Honing?

Vapor honing is a surface refinishing process. Operators use the process to clean and restore surfaces.

However, operators do not use dry abrasive media when performing wet blasting, as they do with sandblasting. Instead, they use a combination of compressed air and water.

The mix that results is called slurry. The slurry also contains detergent and fine, gentle media. The media help to remove oxidized metal and other forms of corrosion.

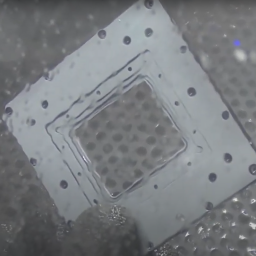

When refinishing aluminum, for instance, vapor honing seals the pores of the metal. As a result, the finished product looks better compared to sandblasting. The process results in a shinier and much smoother surface.

Wet blasting looks just like sandblasting to the untrained eye. The only difference most people will notice is that the process includes the use of water.

However, vapor blasting and sandblasting are two completely different processes. The difference lies in the way that the two practices achieve finishing results.

With vapor honing, you can use a variety of abrasive and nonabrasive materials. These materials might include glass or ceramic beads. They might also include plastic.

The vapor blasting process involves mixing these materials with water. It then propels the materials at a high speed. More importantly, it produces phenomenal results.

Vapor Honing vs Sandblasting

It helps to take a closer look at the differences between vapor honing and sandblasting.

Vapor honing smooths surfaces with the use of abrasive media and water. Sandblasting, on the other hand, restores surfaces with the use of impacts and sheer force. This treatment is typical of a conventional dry blasting procedure.

For this reason, vapor honing eliminates negative characteristics such as media impingement. Also, the process creates a peening effect. Resultantly, surfaces stay cleaner for a longer amount of time.

During vapor blasting, the water used for the process serves as a lubricant. In a way, the water creates a protective barrier. The water shields the surface from the abrasive media.

Nevertheless, vapor blasting enables operators to restore areas that are inaccessible using dry blasting. Furthermore, vapor blasting does not generate heat, as does the sandblasting process.

During the blasting process, excessive heat can distort parts. Even worse, the heat can misshape parts beyond repair. Most importantly, however, vapor eliminates the need to use toxic chemicals to refinish a surface.

Different Processes, Different Results

Because vapor honing and sandblasting are two very different processes, they produce very different results. When using vapor blasting, there are a few process deviations that you can expect during the blasting process. Here is where the difference between vapor honing and sandblasting starts to come to light.

Vapor blasting results in much lower levels of substrate erosion. This benefit is due to the cushioning effect of wet blasting. With sandblasting, abrasive media contacts the refinishing surface directly.

Furthermore, vapor blasting allows for a much more consistent surface finish. What’s more, you can accomplish this uniform finish over a much larger surface area.

The nature of vapor honing creates a different flow compared to sandblasting. For this reason, you can create a larger blast pattern with vapor honing.

Also, vapor honing enables you to apply an equal abrasive action to an entire surface. For this reason, you’ll experience much less smudging and moving of surface material. Again, this benefit is due to the barrier effect created by the water used for vapor honing.

Vapor blasting also results in a cleaner surface. In a sense, the process is like applying two treatments at once. When using vapor blasting, you’re refinishing a surface with both high-speed water and abrasive materials.

Finally, vapor honing enables you to achieve an unparalleled level of minimal surface roughness. Mesh is a measurement of particle size. With abrasive media of a mesh of 400 to 1,200 or higher, you can create remarkable surface smoothness.

Advantages of Vapor Honing

The nonabrasive effect of vapor honing is one of the top benefits of the wet blasting process. You can even use the vapor honing process for delicate surfaces and substrates. In this case, you’d use a very fine abrasive medium.

Vapor honing is a very versatile process. It offers much more flexibility compared to sandblasting. For this reason, there’s a growing demand for wet blasting cabinets.

In addition to flexibility, vapor honing is also healthier and safer for operators. Furthermore, the process offers increased comfort—especially for operators who use blasting equipment regularly.

With sandblasting, there’s a great deal of dust exposure involved in the process. The dust used for sandblasting can make the process quite miserable.

With vapor honing, there’s no need for a dust collector system. For this reason, vapor honing equipment also takes up less space.

Furthermore, wet blasting is quieter compared to sandblasting. It also offers improved visibility when working on projects. For this reason, more operators and shops are choosing vapor blasting for refinishing.

Why Does It Work Better

Vapor blasting works better because it uses water to polish the finished product. The water creates a flushing action. As a result, it can produce a finer finish.

With sandblasting, the media can get buried in the surface of refinished materials. Vapor blasting, however, eliminates this problem.

Sandblasting also creates dust when the media used for the process breaks apart. However, vapor blasting eliminates this problem as well.

Vapor blasting equipment makes use of a special glandless polyurethane pump. The pump agitates the water and media. This agitation creates an abrasive slurry.

Next, the system delivers the slurry to the blast nozzle. The slurry travels through the pump using a series of hoses in the machine.

It takes approximately two bars of pressure to pump the slurry to the nozzle. At the blast nozzle, the system introduces compressed air to the mix.

This action accelerates the slurry. The acceleration gives the slurry the force needed to impact with enough force to refinish surfaces.

After contacting a surface, the slurry will drain into a sump. The sump will then recycle the slurry for reuse.

It will prepare the slurry for reuse by routing it through filters. The filters will remove any additional sediment. This circuitous travel creates a recirculating blasting system.

Vapor Honing Media

There are different types of abrasive media that you can use for various projects. For example, you could use round media for a refinishing project.

It’s available and stainless-steel shot, glass beads, and ceramic. Ceramic and metal beads, however, last much longer compared to glass beads.

Operators use round media for a variety of applications. Round beads leave surfaces clean and bright. They also descale.

Alternatively, you might use plastic angular media. Plastic angular media works well for stripping paint. It’s also ideal for deflashing plastic parts and removing other types of flash.

Next, there’s angular grit. Angular grit media is a very abrasive compound.

Among angular grit media, you might choose steel grit or crushed glass. You might also select aluminum oxide or silicon carbide materials.

Typically, operators will use angular grit media for blasting hardened services. This media works well for removing rust. It’s also ideal for removing grease and heavily scaled surfaces.

Finally, you may use fine angular grit. Fine angular grit works well for cleaning deep into the pores of surfaces. It’s also ideal for prepping for coatings.

Who Can Benefit From Vapor Honing?

You might wonder if vapor blasting will work well for your purposes. If you use equipment designed for power washing or any form of abrasive blasting, you will find that vapor blasting is very beneficial. In fact, anyone who regularly builds or works with equipment that needs cleaning can benefit from the process.

You may choose vapor honing to increase your output. Alternatively, you may want a washing system that results in cleaner parts.

Also, you may have grown tired of cleaning up a dusty mess in your shop. Vapor honing can provide you with these kinds of benefits.

The biggest benefit of vapor honing is that it’s a dual process. It combines both abrasive blasting and power washing in a single operation.

By performing these two functions at once, you can increase your performance. You can also reduce the cost of refinishing surfaces.

For these reasons, vapor honing has become a top choice across many industries. The process helps to speed up parts cleaning in a range of applications.

It’s difficult to match the speed and effectiveness of vapor honing using any other blasting process. Furthermore, companies are continually improving the equipment used for vapor honing.

Choosing a Supplier for Vapor Honing Equipment

You may want to save on wet cabinet cost. For this reason, you may have considered building an inexpensive DIY vapor blasting system.

However, it takes years to develop an effective vapor system. Instead, you’ll achieve much better results by finding the right vapor blasting equipment supplier. If you only use vapor honing occasionally, you’re much better off hiring out vapor honing services.

When searching for vapor honing equipment suppliers, it’s helpful to look for a leader in the field. You should look for someone with experience in supplying degreasing and blasting equipment.

You’ll also want a supplier that provides high-quality equipment. Accordingly, it’s important to choose a supplier with a reputation for selling reliable vapor honing equipment.

You should also purchase a vapor honing system that’s easy to install. Furthermore, the equipment should prove easy to maintain.

Also, you’ll want to choose a supplier that provides ongoing support. Your supplier should also offer a range of delivery options. Finally, the ideal supplier will provide a range of payment options.

A Leader in Vapor Honing Supplies

Now you know a great deal more about vapor honing. What you need now is a vapor honing equipment supplier that can help you to meet your needs.

Vapor Honing Technologies has served the refinishing industry for nearly a decade. During that time, we’ve helped companies across all major markets achieve their refinishing goals. Resultantly, we’ve developed an exceptionally loyal customer base.

It’s our mission to offer competitive wet cabinet equipment. What’s more, we proudly offer blasting equipment made in the USA. Furthermore, we back our vapor honing equipment with a lifetime warranty.

Contact Vapor Honing Technologies today at (828) 202-5563 or connect with us online to learn more about increasing efficiency and cutting operating costs with the right vapor honing equipment.