How Does a Bead Blaster Work?

Scientists and ecologists have predicted it for as long as you can remember. Every year, global warming and environmental decline seem to become more visible in our daily lives.

The production of raw materials into goods for manufacturing is taking its toll on the environment.

You might need a bead blaster and you know you should recycle what you can by any means necessary. You know you should be repurposing the waste you create.

Bead blasting and other refinishing methods can help your business conduct its practices more sustainably and responsibly. How your business conserves its waste can say a lot about what you hold to a high level of importance.

This is the message you are sending out to the world.

Besides your environmental practices, different types of blasting media can provide your customer base’s necessary services.

So how does a bead blasting machine work, and what can it do for my services?

Get answers to all these questions and more in this definitive guide. Take your methods and services to the next level.

Is a Blasting Machined Right for Your Work?

A bead blaster is a machine used in metalworking, automotive repair, and many other industries. Bead blasting works with the process of launching “beads” or other abrasives with high powered air toward a surface to strip or refinish it. Bead blasting is also called sandblasting.

Many times this type of resurfacing can save a delicate or rare part or help you in the process of making new parts.

The difference between bead blasting and wet blasting is one is propelling dry abrasive and the other is mixing dry abrasive with water. However the two processes yield similar but different results but, a few components are the same across the board.

Compressed air, a cabinet, a blasting gun, and the preferred form of abrasive will all be in use. These components would be all you need for a resurfacing or stripping project using bead blasting.

Only, you should know, the bigger and more coarse the “bead,” the more abrasive the impact.

When you consider if you should include bead blasting in your menu of services you offer, you should consider the size and scale of your operation. Weigh the amount of money you will spend as a business owner. Also, do you want to send parts out for finishing or do this process in-house.

Do you have someone on staff who is trained in bead blasting? Is this person familiar with the process and how to use different abrasives to get different results? Can you afford to provide training?

You should also think about if you own or can afford the required machinery for this type of work.

Yes, the equipment needed for bead blasting is much more affordable and sustainable than other refinishing, but it does require specific equipment and skill to operate correctly.

The Difference in Materials

Say you’d like to refinish a dense metal alloy. Maybe a softer metal? How about plastic?

If you are working with metal ideally you need to be more aggressive for coating prep or surface smoothing. Because the material you’d be stripping or refinishing is tightly compact. It can handle a considerable about of surface erosion compared to softer items such as plastic.

Suppose you were planning to refinish plastic or softer material. In that case smaller or softer abrasives need to be used depending on the desired results.

Keep in mind selecting the right abrasive determines how much erosion on the surface of the part and this could compromise its structural integrity. Proper training is essential here. Your employees will need to know what to look for when in the process of bead blasting. The need to understand blasting pressures and abrasive types and sizes.

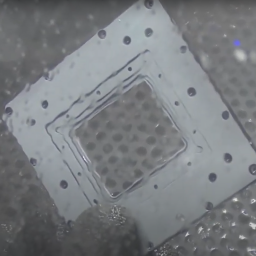

Bead blasters are versatile machines when used with the appropriate blasting abrasive. They help to make an otherwise wasteful business sustainable. In automotive shops, blasting can remove rust before painting. In cnc machining they have been used for coating prep of parts.

Specialists perform the process on many surfaces without core damage because they use the appropriate beads and air pressures for blasting. Bead blasting can even add a decorative etching on glass or stone.

Determine what type of materials you’d like to refinish. Then you can consider the level of abrasion you’d need to be using in your work only after this should you make your selection for the type and size of beads you will use.

What Is a Bead Blaster and How Does It Work?

Many different types of “blasting” can be utilized to refinish all different kinds of surfaces. Basically, if it is manufactured or assembled into a product—you can likely refinish it. Vapor honing can refinish plastic and metal as well but you have to decide if this process is right for you.

Bead blasting is defined as a propelled stream of air containing abrasive particles that refinish, clean, or strip the surface of natural or human-made materials.

Wet blasting and bead blasting are a similar process. In OEM manufacturing, titanium alloy and other metals become strengthened using a process called “peening.” This process can be done either in a dry blast or wet blast.

The practice increases affordability by prolonging the life of a material used in manufacturing of the part. Wet shot peening is an upgrade in the process of dry-shot peening. Wet-shot peening or bead-blasting uses ceramic beads, stainless steel shot and a lubricant—usually water or another liquid—to strengthen surfaces and wash them simultaneously.

Dry-shot blasting uses the same technique but without any sort of barrier or cleaning agent and water. The dry process can yield similar or different results sometimes more intense peening of the surface but it can’t wash the part at the same time like wet blasting.

Environmental Sustainability

The vapor blaster uses a liquid barrier on the materials it processes. This operation effectively reduces surface friction and heat resulting from normal wear and tear or stress on the material. The friction decreases because the metal has a smooth surface after a bead blasting treatment.

Less friction means fewer repairs. Bead blasting is an effective method for your materials where preservation in durability is a concern. Keeping things intact contributes to the reduction of unnecessary waste.

Abrasive blasting aims to increase the grain refinement of the surface layer of most materials. When the grain shape of metal has altered, the material bond grows more robust on a molecular level.

To illustrate this point, Think of this like the weave of a finger trap getting tighter as you pull. The more pressure you apply to the weave of the trap, the tighter it becomes.

Think of this like the surface of your metal or medium.

The more pressure you use, in general, the greater the peening effect. It can, nevertheless, also make harmful changes to the surface of the material if misused.

Starting at a low blast pressure and increasing progressively to test your process is often a good idea.

Fatigue tests performed on alloys after abrasive blasting show fracturing at a vastly decreased rate compared to materials left untreated.

Bead Blasting Or Vapor Blasting?

Bead blasting has advantages over wet blasting when it comes to surface peening and intensity needed. Also, there are times when the toughest of coatings need to be remove and bead blasting is perfect for this since it can be very aggressive.

If you need a more refined and cleaner process then you should look into vapor blasting and see how it can help your process.

Associated Costs for Your Business

Make sure you are estimating the cost of offering bead blasting services to your customers. The cost of the beads themselves are not the worry here but rather the cost of labor. The cost of this type of work can depend on the size of the surface you plan to refinish.

Different materials will need different sizes or grittiness of beads. You will want to have many different sizes of beads in stock to accommodate requests from your customers. Consider this when you are estimating the costs of providing abrasive blasting services.

Glass beads are generally a low-cost material and are ideal for businesses that will often perform refinishing surfaces. Glass beads can be reused and depending on what’s being blasted can be used for sometime.

Overall, if you’re involved in abrasive blasting in your facility, glass bead is a pretty lousy investment. The equipment, staff, and climate are managed much more effectively with bead blasting.

Often, sand is not reusable, making it more costly in the long term and more expensive and dangerous overall.

If you can only offer to sandblast, make sure you convey this to your customers. Some people coming to you for services need a little education on exactly what types of refinishing bead blasting offers.

Use Better Business Practices

Aside from training and materials, the cost associated with bead blasting and refinishing can be an instrumental investment for your company’s success. If you provide any services to cars or trucks, metal fabrication or manufacturing, refinishing worn metal can end up being your most viable recycling method.

Before, you may have just discarded parts of cars or other machine parts that have seen better days—but now things can be different. You are thinking about your impact and your company’s future.

Developing a method for bead blasting equipment is your best bet at acing the ability to be more self-sufficient. Instead of contacting a manufacturer and ordering expensive parts brand new; you can simply refurbish old parts and give them new life.

This is great for your business practices as well as something practical to do for the environment.

You will be shocked at how often removing dirt, rust and debris can revitalize the entire inner workings of machines. Take the stress of having a stock and inventory off of yourself and your coworkers. Be a more perceptive business and adapt to a changing world.

How a Bead Blaster Can Help Your Business

Being the most sustainable and comprehensive repair shop or manufacturing center should be a priority for your business.

You have realized that a bead blaster can do much more than you ever thought possible.

Imagine that you didn’t have to buy any new metal for your business, and you could use the materials you have refinished and reused. The process alone could pay for itself with all the inventory cost you might save.

Join us and visit our site. While you are there, explore what bead blasting and blasting machine equipment can do for your business.