What Is The Best Way To Remove Rust

Rust is a common problem that occurs when metals come into contact with water, oxygen, and other elements. If left untreated, rust can weaken the metal and cause it to deteriorate over time. Fortunately, there are several ways to remove rust and restore the metal to its original condition. In this article, we’ll explore some of the most effective methods for removing rust, including wet blasting, which is widely considered to be the best method available.

Mechanical Removal

Mechanical removal involves using tools like sandpaper, wire brushes, and grinders to physically remove the rust from the metal surface. This method is best for light to moderate rust and is effective for small areas or objects that can be easily handled. While it is a relatively simple and inexpensive method, it can be time-consuming and requires a lot of physical effort. Additionally, this method is also known to remove small amounts of surface material, which can damage sealing surfaces.

Chemical Rust Removers

Chemical rust removers are specially formulated products that dissolve rust without damaging the metal surface. These products are available in spray or liquid form and can be found at hardware stores or online. They work by breaking down the rust, making it easy to wipe away with a cloth or sponge. While they are effective for removing rust, they can be harsh chemicals that can cause skin and eye irritation, and should be handled with care. While chemical rust removers do remove rust without damaging the part, they are an expensive solution.

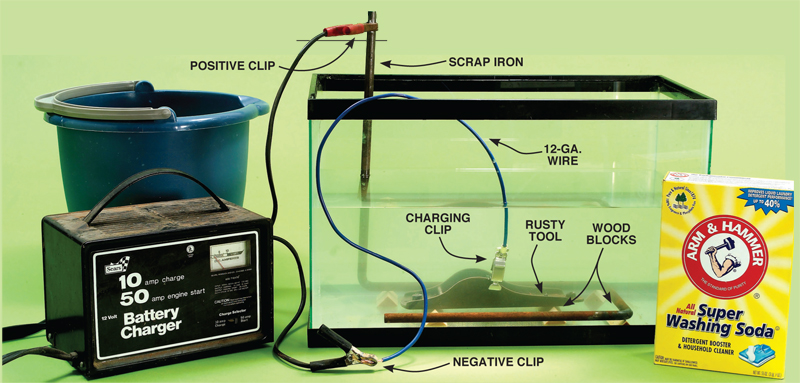

Electrolysis

Electrolysis is a process that involves passing an electrical current through a solution of water and a rust remover. This causes the rust to detach from the metal and collect on a sacrificial electrode. This method is effective for heavily rusted metal objects and requires some specialized equipment. While it is an effective method, it can be expensive and time-consuming, and should be used with caution as hydrogen gas can be produced.

Vinegar and Baking Soda

A mixture of vinegar and baking soda can also be used to remove rust. Mix equal parts of vinegar and baking soda to form a paste, then apply it to the rusted area and let it sit for several hours. This method is effective for light to moderate rust and can be done using household items. While it is an inexpensive and environmentally friendly method, it may not be as effective as other methods and may require multiple applications.

Coca-Cola

Coca-Cola contains phosphoric acid, which can dissolve rust. Pour Coca-Cola onto the rusted area and let it sit for several hours before scrubbing the area with a brush or sponge. This method is effective for light to moderate rust and can also be done using household items. While it is an inexpensive and easy-to-find solution, it may not be as effective as other methods and may require multiple applications.

Wet Blasting – The Best Option

Wet blasting, also known as slurry blasting or vapor blasting, is widely considered to be the best method for removing rust from metal. This method involves using a high-pressure stream of water mixed with an abrasive material, such as glass beads or garnet, to remove rust and other contaminants from the metal surface. The water acts as a lubricant, preventing damage to the metal surface, while the abrasive material removes the rust and other contaminants. This is in contrast to sandblasting, which is another rust removal process that only uses abrasive particles to strip parts.

Wet blasting is incredibly effective at removing rust and corrosion from all types of metal, including steel, aluminum, brass, and copper. It is also an environmentally friendly method, as it uses water as the primary cleaning agent and does not generate harmful dust or debris. The amount of waste generated is also less, as the abrasive in a wet blast cabinet can be reused for over a month. In comparison, the media involved with sandblasting may only last a few cycles.

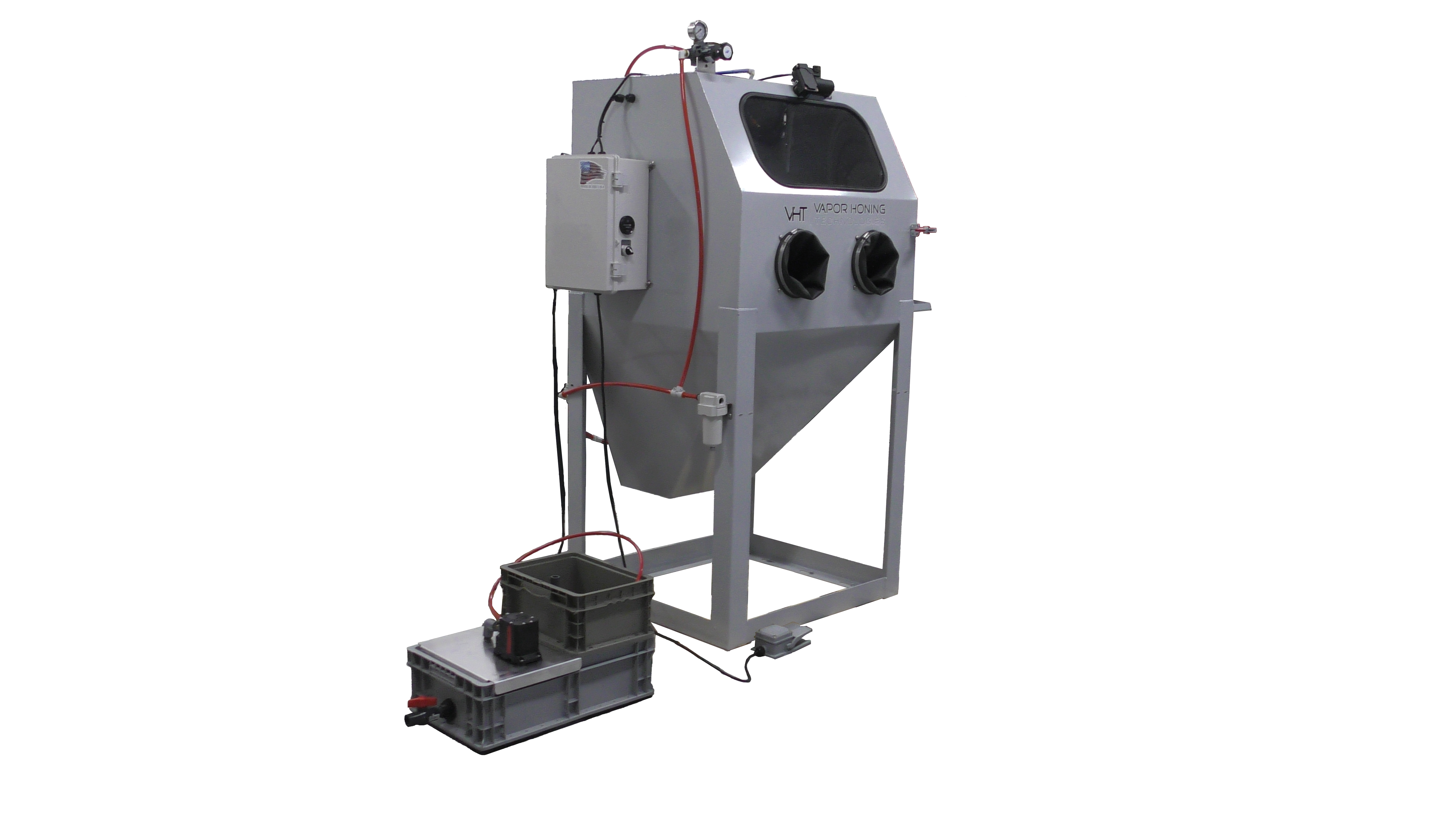

Pictured to the right is the VH800FL Pro

Wet blasting is also a relatively quick method that can clean even heavily rusted surfaces in just a few minutes. This process is also safe on materials such as rubber and plastic, meaning intricate parts can be processed easily. The ability to clean dirty and greasy parts is also a benefit of a wet blasting machine, as the water acts as a natural cleaning agent. This will save you loads of time if you are processing dirtier parts, as they require no pre-cleaning.

Wet blasting and sand blasting are the only two rust removal options that allow you to affect the surface finish on your part. Due to sand blastings high impact force, only rough surfaces can be created through its process. This is alright if you plan on coating the part. Wet blasting can also be used to create the perfect prepped surface for powder coating, Cerakote, and anodizing depending on your spec. Smooth, visually appealing surfaces can also be created using wet blasting, which is magnified with softer metals.

To learn the correct abrasive to use for your click here.

Conclusion

Removing rust from metal can be a daunting task, but there are several effective methods available. Mechanical removal, chemical rust removers, electrolysis, vinegar and baking soda, and Coca-Cola are all viable options. However, wet blasting is widely considered to be the best method, as it is effective for all types of metal, it will not damage soft materials, it requires no pre-cleaning, and it is environmentally friendly. No matter which method you choose, it is important to understand your end purpose when choosing your preferred method of removing rust. If you are looking to remove the rust off of a singular piece, then a chemical approach will suffice. For an antique part that just needs the rust removed, electrolysis becomes a good solution.

If you are looking to do all the above and much, much, more, a wet blasting machine is the perfect solution. There is no need to worry about pre-cleaning the parts you are processing beforehand, and no need to worry about their safety. Additionally, you can custom tailor the finish on your parts through your abrasive choice while not damaging the softer materials on the part!

If you are ready to get the results, you deserve by getting the best wet blasting equipment on the market today into your home, shop, or business, we can be reached at 828-202-5563. Additionally, please call us if you have any questions regarding wet blasting, as we are happy to help.