Vapor Blasting Stainless Steel

Stainless Steel is a metal that is used in a multitude of industrial settings and products. Its strength properties make it an ideal candidate for aerospace and industrial settings, and medical and food handling industries require it for its noncorrosive properties. This begs the question, why should you vapor blast stainless steel since it is noncorrosive, strong, and reasonably attractive raw? The answers may be exactly what you need to take your stainless steel parts and pieces to the next level.

Manufacturing

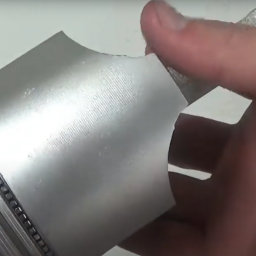

For starters, every stainless steel part must go through some sort of manufacturing before it is sold. If you yourself are a manufacturer, you understand that perceived value is of the utmost importance. Vapor blasting stainless steel will provide attractive finishes that can be tuned to your likings by adjusting the abrasives used. A glass or ceramic bead will provide a brighter finish, whereas an aluminum oxide will create a darker look. An advantage of vapor blasting over sand blasting is the ability to mix abrasives. With traditional sandblasting, the abrasive is not mixed thoroughly enough to provide a mixed finish. This is not a problem with vapor blasting due to our proprietary agitation system. Vapor blasting your stainless steel parts will also leave a uniform finish while removing any manufacturing blemishes. With a better looking product, selling more will be easy!

Surface Roughness

As stated earlier, changing the abrasives used when vapor blasting affects the characteristics of your parts, aka its profile or surface finish. The profile of your part can be measured as surface roughness, and this tells you how smooth or rough the surface is on a microscopic level. For any industry involved with the interactions of metal and another substance, surface roughness is of the utmost importance. Whether that is how two sealing or meshing surfaces will interact in an engine, or how tissue will attach to an implant, surface roughness will dictate it. Our Vapor Honing machines are the tool many companies use to manipulate the surfaces of what they manufacture. We have a vast knowledge of abrasives and can assist you in taking your surface roughness refinement to the next level.

Perceived/Actual Value

Finally, for those that are cleaning or re-manufacturing stainless steel parts, vapor blasting is an outstanding solution. Because water is mixed with abrasive in our machines, cleaning and blasting can be completed at the same time! When vapor blasting old parts, you do not have to worry about data plates or sealing surfaces being affected due to its “clean by flow” nature. Vapor blasting stainless steel will yield OEM like results on any part. Having a part that looks and functions correctly is intuitively worth more. So by increasing your actual and perceived value increase, you make more money, and with the affordability or vapor blasting, its a no-brainer.

Conclusion

So whether you are producing, remanufacturing, or cleaning stainless steel parts, vapor blasting is the perfect solution to increase their value. Vapor blasting can also reduce your processing time. For any questions about vapor blasting or what it can do for you, call our sales team at 828-202-5563. Thank you for reading, to learn more about this technology check out our other blogs here. We hope this blog has been helpful!

Have a great day