How to Choose the Right Vapour Blasting Machine

Learn about the many different features of vapour blasting equipment and how to buy the correct machine for your needs and still within your budget.

Benefits of Vapour Blasting

- Eliminate the hazardous dust mess in your factory or workshop.

- Replace chemical processes used for cleaning, stripping, & etching.

- Eliminate expensive hazardous waste disposal fees.

- Improve worker safety with lower decibel levels compared to dry blasting machines.

- Improve operator productivity with better machine ergonomics.

Our Customers

[supsystic-price-table id=28]

What is Machine Filtration For?

- Uses water from this external basin system to rinse your parts internally reducing fresh water consumption and helps eliminate abrasive lost from the machine.

- Filter oils, contaminates, broken down abrasive, and other solid particles that overflow from your machine hopper. Oil absorption cloth absorb oils and solvents while solids settle in the basins to be disposed of at a later date.

- Added convenience factor if your budget allows.

What slurry pumping system do you use?

Industry proven high volume submersible systems with polyurethane impellers. Impellers are abrasion resistant to withstand the harshest conditions. Our heavy industrial pumps come backed with a two year warranty. We have yet to have any of our pumping systems fail in the most extreme environments.

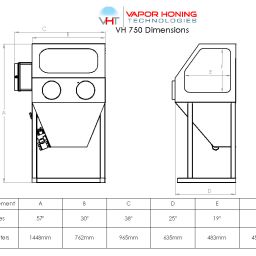

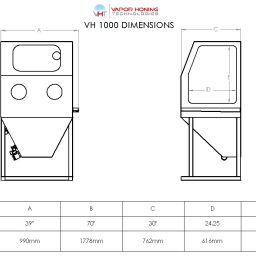

Determine machine size ?

- Ergonomically you need plenty of room to spin your part internally to work efficiently. If parts are large and heavy turntables are highly recommended.

- Keep in mind large spaces can also work against the operator as well especially when parts slip from the grip of the operator and travel to the back of the machine.