What is Abrasive Blasting?

What is abrasive blasting? This is a term that’s used very loosely in the industry that could be explaining many different forms of blasting.

In general abrasive blasting is when you shoot pressurized air mixed with dry abrasive or abrasive mixed with water at a part or surface.

There are other terms used within the industry to describe abrasive blastings such as sandblasting, gritblasting, wet blasting, dry blasting, or media blasting. These processes have many different outcomes such as:

- Smoothing surfaces

- Deburring parts

- General cleaning

- Rust removal

- Coating prep

- Finishing surfaces

- Descaling or degreasing

- Bonding Prep

There are many different types of abrasives being used to complete the above jobs. Usually, there is no one size fits all solution and results can be tailored depending on the abrasive and pressures used. Below are some examples.

Types Of Abrasive Media Used

- Dry Ice

- Walnut Shells

- Pumice

- Corn Cobs

- Ceramic Grit

- Ceramic Bead

- Stainless Steel Shot

- Steel Shot

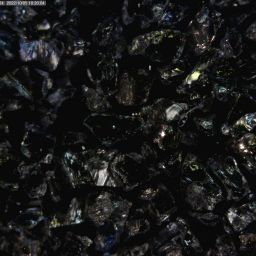

- Steel Grit

- Wire Grit

- Coal Slag

- Crushed Glass

- Copper Slag

- Plastic Grit

- Aluminum Oxide

- Glass Beads

- Garnet

While each abrasive above is chosen based on the size of abrasive and hardness or the abrasive needed for the job. The job will often need to be tested before the final selection is made. At Vapor Honing Technologies we have free application testing to help with your selection of abrasive.

How does abrasive blasting work?

Abrasive blasting can be accomplished using three main components such as:

- The blasting cabinet or blasting pot

- Air compressor to force the abrasive mixture

- Blasting Gun for directional control of the blast

In a controlled environment such as a blasting cabinet or a blasting room, this is the main abrasive blasting process used. There are external machines or pressure pots used for larger outdoor projects such as bridge blasting, boat blasting, or graffiti removal.

Difference between dry blast vs wet blast

Dry blasting is propelling dry abrasive at a part surface to clean or prepare a part or surface. Dry blasting was the first blasting process ever invented. However many years later wet blasting was discovered for a few different reasons to be superior in many cases.

Dry blasting machines can be built two different ways. Direct pressure using a pressure pot to force abrasive to the blasting nozzle. Or often cheaper options such as a suction system. In a suction cabinet, the blasting nozzle creates a venturi effect when compressed air is added creating the suction pulling the abrasive up to the blasting gun to be shot at the part.

Normally direct pressure machines are more expensive than suction blast cabinets. Direct pressure machines have an easier time pushing larger heavier abrasives through to the blasting gun whereas suction machines would struggle to provide adequate abrasive flow to the blasting gun causing major inefficiencies.

Often times in the industry the suction vs direct pressure conversation is also in the wet blast side. However, all wet blast machines are considered to be direct pressure machines due to the slurry pump system pushing the abrasive and water mix to the blasting gun. There are many benefits to this setup but mainly the equal mixing of the water and air and the consistent delivery to the blasting gun are the main reasons.

Wet Blast Benefits

In a wet blasting system, the biggest advantages over dry blasting are the ability to blast with smaller abrasives into the 1200 mesh range. Therefore, dry blasting machines cannot feed this fine material.

Other benefits from wet blasting are the lack of dust when blasting, and the flow base nature of the blast cleaning even the smallest and tightest of part surfaces. Also, when the smoothest surfaces are needed wet blasting can achieve those better than any dry blasting process. One final benefit is also the lifespan of all consumables in a wet blasting system.

Abrasive Blasting Types

Bead Blasting-

Using glass bead abrasive this process is used to create smooth finishes. Oftentimes operators also use glass beads to do general cleaning of parts as well.

Shot Blasting-

Round steel or stainless steel shot are used to create compressive strength on a surface to help eliminate surface cracking increasing overall part strength. Shot blasting can also be used for a quick cleaning in the remanufacturing industry where speed is of utmost importance. In addition, this method can be performed in a blasting cabinet or in special shot blasting machines which used wheels to sling the abrasive at the part.

Wheel Blasting-

These machines used spinning wheels at high RPM’s to sling abrasive at the part. This process uses no compressed air to propel abrasive at the part. Wheel blasting is commonly used in the remanufacturing industry for its speed of cleaning.

Soda Blasting-

Using Armex blasting soda is a cleaning process in which blasting soda is only used once and then disposed of. Due to its higher cost, it is not a common option for cleaning applications. The main attraction to soda blasting is the fact that the soda dissolves in water or oil leaving no abrasive behind for extra cleanup. It is also used in other restoration projects such as automotive, fire or smoke removal, and rust removal.

Wet Blasting –

The finest finishes all while creating no dust can be achieve. Wet blast also extends the consumable lifespan decreasing the overall operating cost of blasting. I have found no process in which wet blast isn’t good. There are hundreds of applications for this process and the lifespan of the equipment increases allowing the higher cost of the machines to be disperse over a longer period making the machines cheaper than conventional dry blasters.

Dry Ice Blasting-

Blasting dry ice pellets at a part removing greases or another surface contaminates. This process is useful when abrasives cannot be left behind after the blasting process.

Industries Using Abrasive Blasting

- Shipbuilding and hull cleaning

- Automotive repair and restoration

- Construction and contracting

- Metal finishing

- Welding

- Metal casting and foundry work

- Powder coating

- Wet Painting Prep

- Surface preparation

- Glass Engraving/ Etching

- Concrete

- Monument engraving

If you have questions on the different blasting processes and how they might be able to help you just give the sales team a call or shoot us an email. We have more than 20 combined years of abrasive blasting experience and thousands of companies that we’ve helped with the most challenging projects. Whether you need dry blasting help or wet blasting help we can support your next project. We strive for success by offering a lifetime warranty on all equipment and the highest level of customer satisfaction/ support.

Contact us today

(828)202-5563

info@vaporhoningtechnologies.com

To watch more content like this visit our YouTube channel below