What Is Wet Blasting?

Wet blasting is your new and best way to clean your chosen surface such as aluminum, steel, Stainless Steel and so much more. Some people prefer dry blasting but wet blasting is proven to be safer for you and your chosen surface.

When it comes to efficiency, safety, and overall productivity of a machine, why wouldn’t you go with the best?

Keep reading to find out exactly what wet blasting is and how it can help you.

Does wet blasting make a difference?

Wet blasting is the process of using high-pressure water with abrasive particles to reach the desired cleanliness and finish on a variety of surfaces. This means it is far more effective than a simple spray cleaner and a rag

Since this is most commonly used on items such as automotive parts and cnc machined parts, you can imagine that it needs to be strong enough to remove even the hardest substances.

Although you may wonder what the difference between a wet blaster and a pressure washer is. It all comes down to one thing that shows the quality difference and thats the abrasive particles and pressure differences. Pressure washers just spray water at high forces but the wet blasting is stripping the surface of imperfections and dirt at lower pressures. This means you have a choice of finish on your chosen surface.

You are able to use wet blasting on items as big as car engine components and as small as nuts and bolts. There are different types of machines that handle different size items.

Just to see some amazing results of wet blasting you can view these photos to see what items look like before and after someone uses a wet blaster on them.

Is wet blasting better than dry blasting?

The short answer to this question is: yes. Although many people would disagree, there are many more advantages to wet blasting than there is for dry blasting.

The difference between the two is simple. Both go through the same process and use the same materials except wet blasting has one crucial difference. It adds water to the equation which helps rinse away the blasted surface.

Dry blasting use to be the preferred way of finishing and cleaning a chosen surface because there was no waste and it did the job it was intended to do.

Once wet blasting was created, many people switched to it because it was, and is, considered to be safer than dry blasting. The reason for the creation of wet blasting was the need for a different level of process control and final surface finish.

Even if that need didn’t arise, wet blasting would have still been added to the market as superior to dry blasting.

Why is wet blasting better?

If someone asks you to clean a table but you have the choice between air and water which would you choose? The obvious answer is water because it is a natural cleaning agent.

That is what people were finding when trying out dry blasting versus wet blasting. Although dry blasting will produce a similar effect it produces quite a bit of dust. After working hard to get the desired finish on your chosen surface, why would you want it covered in dust?

Wet blasting is a self-cleaning process that will save you time in the long run. Although there is water waste that is produced in some applications but not all, many shops and places that use wet blasting will have drains or procedures in place to remove the excess water.

The goal of blasting is to get a clean finish on your chosen surface which is why wet blasting is ore superior to dry blasting. You can use wet blasting on a bunch of materials, such as plastics, metals, synthetics, composites. Anything that can be submerged in water can be used in wet blasting.

Additionally, wet blasting is less aggressive. The last thing you want is for your surface to get damaged. Water is a lubricating substance that creates a barrier between the abrasive material and the surface. This means it will leave your surface in perfect condition.

Why is wet blasting safer?

One danger that comes with many professions such as construction and auto body shops is dust. Dust can be very dangerous for people in these professions which is why they wear safety goggles and masks to filter the air around them. Also, dust mixed with powdered metals being blasted away from the surface can also become explosive and dangerous in dry blasting systems.

Dust can get in your eyes and cause vision damage but even worse is it can get into your lungs and cause long-term illness and damages.

By adding water, it solves the dust problem. The dust particles get trapped in the water instead of into the air.

Additionally, wet blasting is more consistent than dry blasting. When it comes to working on machines, any sense of unpredictability can be dangerous. By using wet blasting, it gives a more consistent and controlled version of cleaning.

It is the more environmentally safe version because it doesn’t use any harsh chemicals. Chemicals can damage surfaces and leave them more dangerous to touch. Not to mention the dangerous effects they can have on people and the environment.

Wet blasting doesn’t need any chemicals because the water is the lubricant and the suspended material will clean better than any chemicals. Many machines will even recycle the water so it isn’t wasting water.

What should I use for wet blasting?

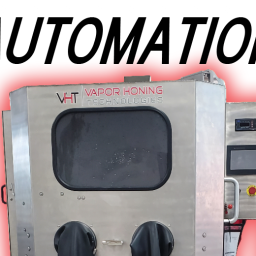

When looking for a wet blasting machine there are three types of machines that people usually buy. Many wet blasting companies use all of these machines because they work on different size items and different materials. There are manual, automatic, and robotic.

If you are looking for a machine to use in a personal shop you should go with the manual machine.

With this machine, you put your hands in a pair of gloves and can manipulate the object you are cleaning. These machines tend to be more user-friendly and less like to need maintenance.

The second is automatic which involves conveyor belts, turntables, and other mechanical components. These are more often used in factory settings because you clean many objects in a row. This means faster and more thorough work being done.

Lastly, you can get a robotic system. This essentially is a set it and leave it type of process. The robotic system does everything you need it to, it is faster and more efficient than the previous two machines.

What should I look for in a machine?

Just like with any other machine, it depends on the project you are working on. They come in different sizes with varying features. Somethings to consider when looking to purchase some equipment are:

- Abrasive Material

- Blast Cabinet

- Air Pressure

The abrasive material

You can choose which material will be suspended in the water which is important because each produces different results on your chosen surface. The abrasive material is also called media.

Some common abrasive materials are silicon glass beads, aluminum oxide, and other plastics. Using these materials can produce polished finishes and cleaning or cutting effects.

Silicon glass beads are often the most popular because they tend to focus on the cleaning aspect of wet blasting. Before creating a finish the surface must be cleaned silicon glass beads are the best option for that.

If you want something with a surface profile for coatings, aluminum oxide is the best option. They are in a hexagonal shape which leaves surfaces etched and it works on all material types that need prepared for coatings or aggressive cleaning.

Lastly, if you want something to be cut you would want a hard abrasive material such as silicon carbide or boron carbide.

Choosing the correct abrasive material is crucial because you don’t want to risk damaging the surface you are trying to clean. Each material produces the desired finish but choosing the wrong material can cause problems in the wet blasting.

The blast cabinet

There are many choices in blast cabinets but it usually falls into two categories: lightweight and heavy-duty. The lightweight tends to be made out of plastic while the heavy-duty is made out of stainless steel.

Choosing the right blast cabinet comes down to what you are using it for as well as the size of the space you will be putting it into.

Air Pressure

To get your desired finish, you must take into consideration how much power your machine has. Not enough power will not make a difference on the surface you are trying to clean and finish.

The PSI (pound per square inch) is important in deciding when you are choosing your material. Softer and more delicate materials can get damaged if there is too much pressure from your machine.

What can wet blasting remove?

When you decide to use wet blasting, you probably either have something you want to clean or something you want to remove.

There are a few common questions that people ask about wet blasting:

Can it remove rust?

It can remove rust! Rust is a large problem when it comes to anything automotive because it damages important parts of the vehicle. If you have dealt with rust, you know how important it is to remove it.

You can use your wet blaster to remove the rust in a more controlled way. As stated before, wet blasting is more controlled which means you can focus on certain areas without needing extensive part masking or highly experienced operator control.

Can it remove paint?

One of the best features of wet blasting is its ability to remove paint. Gone are the days of scraping paint or dry blasting paint and destroying your surfaces.

Wet blasting can remove stubborn paint safely because no particles will be launched into the air or extensive part warping and distortion. It can be used to removed paint off of many materials so you can safely start repainting.

Can it remove grease?

Especially in the automotive industry, grease is a common substance found on surfaces in the engine. Although you can take a rag and spray to clean the surface, it would be much easier to use a wet blaster.

Because the water in the wet blasting is less aggressive than dry blasting. You will be able to see the grease easily run off the surface instead of spraying it around. Also, with the addition of heated sumps and de greasing agents the oily substances literally melt away.

What can I do after the surface is wet blasted?

It is a common misconception that after you wet blast your material is done and you won’t have to do anything to it. That is both right and wrong.

You certainly can just take your material or item and use them right away but not everyone wants to do that.

Wet blasting can be a great prep step to do before you paint or polish an object. It is creating a smooth and clean surface for you to use for your further projects.

Because wet blasting doesn’t use any chemicals, there won’t be a reaction between what is on the surface and whatever you are putting on. The water does most of the work and very few things will react poorly with water.

That is why if you are looking to add paint or polish after something is blasted, you should go with wet blasting rather than dry blasting.

How do I get started?

If you have something you want to get wet blasted, you have two options. Either you can buy a machine yourself and do it at home or you can send your parts to a professional who can do it for you. Either way, you will be able to get the results you are looking for.

Make sure you go back to consult the list above to make sure you are buying the correct machine and abrasive material for your needs.

From there you will be able to buy everything you need to start your wet blasting and start cleaning all your chosen surfaces.