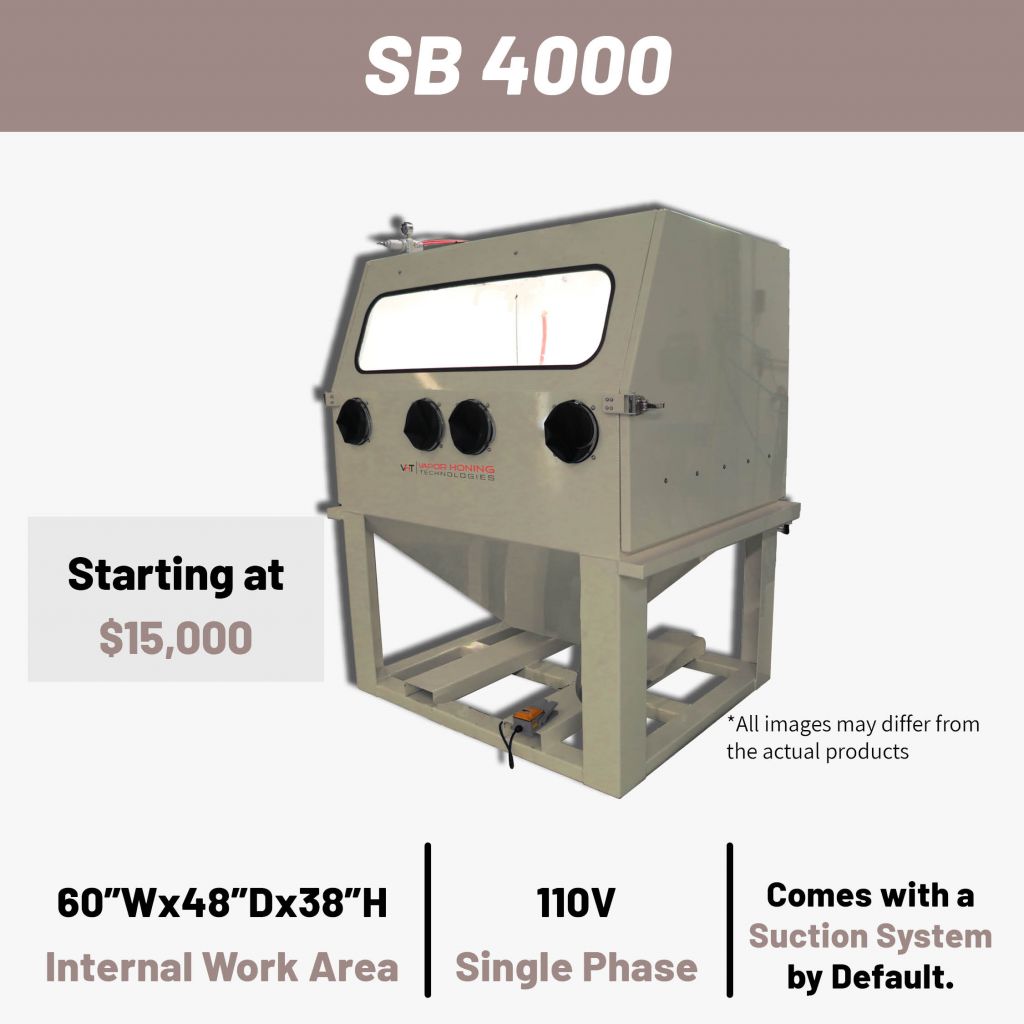

| Internal Working Dimension | 60″ W x 48″ D x 38″ H |

| Power | 110V Single Phase |

| Abrasives Amount | 40 lbs. |

| Abrasive Delivery | Metering Valve |

| Gun Tips | Ceramic Tips |

| Collection System | Reclamation System |

| CFM | 20-30 Per Blast Gun |

| PSI | 60-100 PSI |

| Assembly | No Assembly Required |

-

100% built in the USA

-

American tech support Monday – Friday

-

Built to last and work non-stop

-

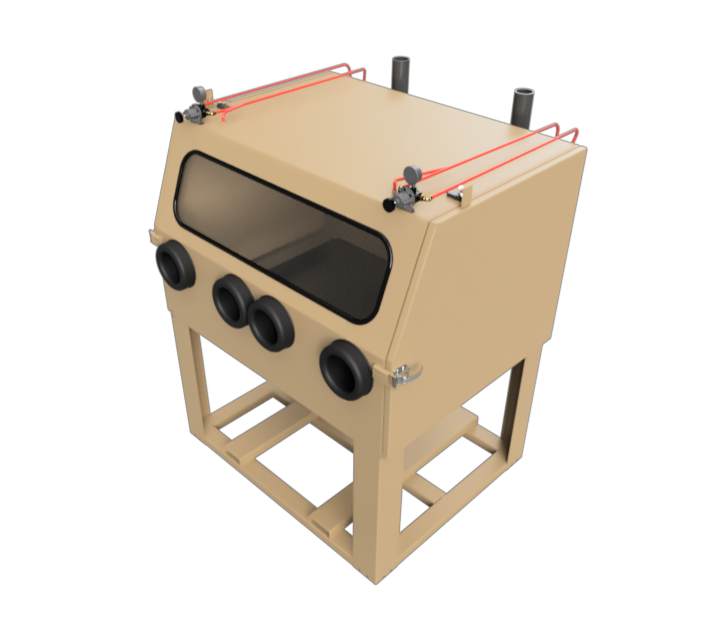

Fully welded hopper to prevent spillage

-

Constructed of robust mild steel

-

Powder coated for longevity

-

Large loading doors on both sides

-

Dual operation upgrade available

-

Includes precision regulator

-

GFCI plug is standard

-

Foot pedal operated for ease of use

-

Large LED light bars for excellent visibility

-

Advanced reclamation system for safety and visibility

-

Reclamation system is necessary for tight process control

-

Simple control box for quick control

-

Heavy duty floor supports for large parts

-

Multiple turntable configuration

-

Door switches added for safety

Discover the SB4000, a Sandblasting Cabinet by Vapor Honing Technologies – a revolution in surface treatment.

With dimensions measuring 60″ W x 48″ D x 38″ H and boasting dual large loading doors on both sides, this cutting-edge cabinet offers unmatched versatility and convenience. But it doesn’t stop there. The SB4000 can also come equipped with the dual-man station upgrade, enabling two operators to work together. Whether you’re working with intricate parts or large components, this powerhouse can accommodate them all. From automotive restoration to industrial cleaning, the SB4000 elevates your surface treatment capabilities and dramatically enhances efficiency. Don’t just meet industry standards; set new benchmarks with Vapor Honing Technologies’ latest offering.

- What is sandblasting?

- What are the primary applications of sandblasting?

- Is sand always used in sandblasting?

- Is sandblasting safe for operators and the environment?

- Can sandblasting be used on all surfaces?

- Sandblasting is a surface preparation technique used to remove paint, rust, corrosion, and other contaminants from various surfaces. It involves propelling abrasive materials, such as sand, at high speeds using compressed air or other methods to clean or prepare a surface for further treatment, like painting or coating.

- Sandblasting is commonly used in various industries, including automotive, construction, manufacturing, and shipbuilding. Some common applications include removing old paint or coatings, cleaning metal and concrete surfaces, etching glass or stone, and preparing surfaces for painting or welding.

- Sand was historically a common abrasive material in sandblasting. Today, safety and environmental concerns have led to the use of alternative abrasive materials like garnet, aluminum oxide, glass beads, and plastic media. The choice of abrasive material depends on the specific application and the surface being treated.

- Sandblasting can be hazardous if proper safety precautions are not followed. Operators should wear personal protective equipment, such as respirators, goggles, and protective clothing, to prevent exposure to airborne abrasive particles. Additionally, proper containment and dust collection systems are essential to minimize environmental impact and protect workers from harmful dust and contaminants.

- Sandblasting may not be suitable for all surfaces, as it can be too aggressive and potentially damage delicate materials like wood or thin metal. The choice of abrasive material, blasting pressure, and technique must be carefully selected based on the surface type and the desired outcome. In some cases, alternative methods like Vapor Honing, soda blasting, or dry ice blasting may be more appropriate for sensitive materials.