| Internal Working Dimension | 33″ W x 30″ D x 28″ H |

| Power | 110V Single Phase |

| Abrasives Amount | 25lbs. |

| Abrasive Delivery | Siphon Tube |

| Gun Tips | Ceramic Tips |

| Compressor Specs | 7.5 HP or Larger |

| CFM | 20-30 CFM |

| PSI | 60-100 PSI |

| Assembly | No Assembly Required |

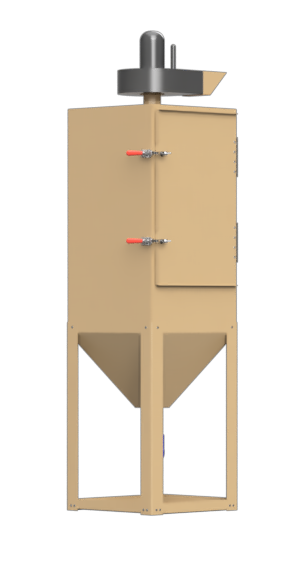

| Dust Collector | Optional Upgrade |

-

100% built in the USA

-

American tech support Monday – Friday

-

Large window for easy viewing

-

Fully welded cabinet prevents any abrasive from slipping through

-

Machine made of robust mild steel

-

Comes with GFCI 110V plug

-

Standard air regulator

-

Foot switch operated blasting gun for simple process control

-

Bright LED lighting for excellent visibility

-

Right-hand side load door

-

Aircraft grade aluminum door for durability

-

Simple electrical box for ease of use

-

Perfect height for sitting or standing

-

Abrasive drain located underneath for easy change out

- What is sandblasting?

- What are the primary applications of sandblasting?

- Is sand always used in sandblasting?

- Is sandblasting safe for operators and the environment?

- Can sandblasting be used on all surfaces?

- Sandblasting is a surface preparation technique used to remove paint, rust, corrosion, and other contaminants from various surfaces. It involves propelling abrasive materials, such as sand, at high speeds using compressed air or other methods to clean or prepare a surface for further treatment, like painting or coating.

- Sandblasting is commonly used in various industries, including automotive, construction, manufacturing, and shipbuilding. Some common applications include removing old paint or coatings, cleaning metal and concrete surfaces, etching glass or stone, and preparing surfaces for painting or welding.

- Sand was historically a common abrasive material in sandblasting. Today, safety and environmental concerns have led to the use of alternative abrasive materials like garnet, aluminum oxide, glass beads, and plastic media. The choice of abrasive material depends on the specific application and the surface being treated.

- Sandblasting can be hazardous if proper safety precautions are not followed. Operators should wear personal protective equipment, such as respirators, goggles, and protective clothing, to prevent exposure to airborne abrasive particles. Additionally, proper containment and dust collection systems are essential to minimize environmental impact and protect workers from harmful dust and contaminants.

- Sandblasting may not be suitable for all surfaces, as it can be too aggressive and potentially damage delicate materials like wood or thin metal. The choice of abrasive material, blasting pressure, and technique must be carefully selected based on the surface type and the desired outcome. In some cases, alternative methods like Vapor Honing, soda blasting, or dry ice blasting may be more appropriate for sensitive materials.