How Automation Improves Workflow

Do you feel like you could improve the efficiency of your manufacturing process? Well, an automated wet blasting unit can help with that. Here is how automation improves workflow in your workshop.

Repeatability Improves Workflow

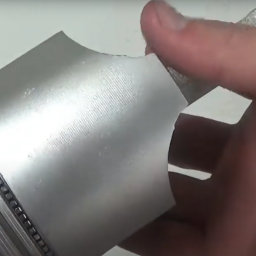

Your workshop’s workflow significantly improves due to the repeatability of automation. All you have to do is program the robot arm once for a particular part and it will blast it that way every time in the same time span. This is great if you are blasting hundreds or thousands of parts each day. With the repeatability factor of automation your parts have a consistent finish. Whereas, with manual blasting we might think we are hitting all angles, but in fact we might be missing some on one part and hitting that area on another. Thus leaving your parts with an inconsistent finish.

You can also get an inconsistent finish if you have multiple people blasting. Everybody blasts differently so your parts can easily come out looking different. Not to mention some people are going to blast quicker than others. When a fast person blast that is great because you can finish your projects sooner. On the other hand, a slow blaster can really slow down production rates in your shop. With automation, it is the same arm every time, and it utilizes the same movements. This leaves you with a consistent finish on all your parts, and a consistent completion rate. This consistent rate of completion will overtime increase the rate of production because you have a general idea of how long the project will take. This eliminates the estimation game when processing parts, meaning you can correctly gauge your work.

Maneuvering Improves Workflow

An added benefit of automation’s maneuvering is that you get a better clean on your parts. Since the robot is programmed to hit all angles, it is more likely to leave your part with a better clean. Whereas, a human might miss the correct angle by a little and, in doing so, miss a small part of the surface. In our Robo IQ blaster, the turntable allows for indexing style blasting of smaller parts, and full access to large parts. This means that no area of your part will be left untouched if that is desired. We also offer custom automated machines. We have accommodated 40 foot pipes, pans, wires, blades, engine parts, and more in the past, so if your process needs it we can build it.

Freeing You Up

While you are using automation on your parts, you can work on other projects improving your workflow. This is incredibly important in current times, as high-quality employees are few and far between. Instead of having employees manually cleaning parts through any process, it makes more sense to free them up and allow automation to handle it!

Conclusion

Automation improves workflow because you can input the same part into your machine and it will blast it the same way every time. It will also smoothly transition to another area of your part once done with a particular section. Thus, leaving your part very clean and allow you to work on other projects while your parts are blasting. Automation is the next step for any company who wants to grow exponentially as it increases workflow, frees up employees, and provides consistent results. For more information on automation, contact us at (828) 202-5563.