- The VH900 Tumbler is backed by the Industry’s Best LIFETIME WARRANTY

- 100% Built in the USA

- UPGRADE OPTION WITHOUT DEPRECIATION

- American Tech Support Monday-Friday

- Industrial Machine Built to Last a Lifetime

- Stainless Steel

- Precision Air Regulator

- Open Loop System (Closed Loop +$650)

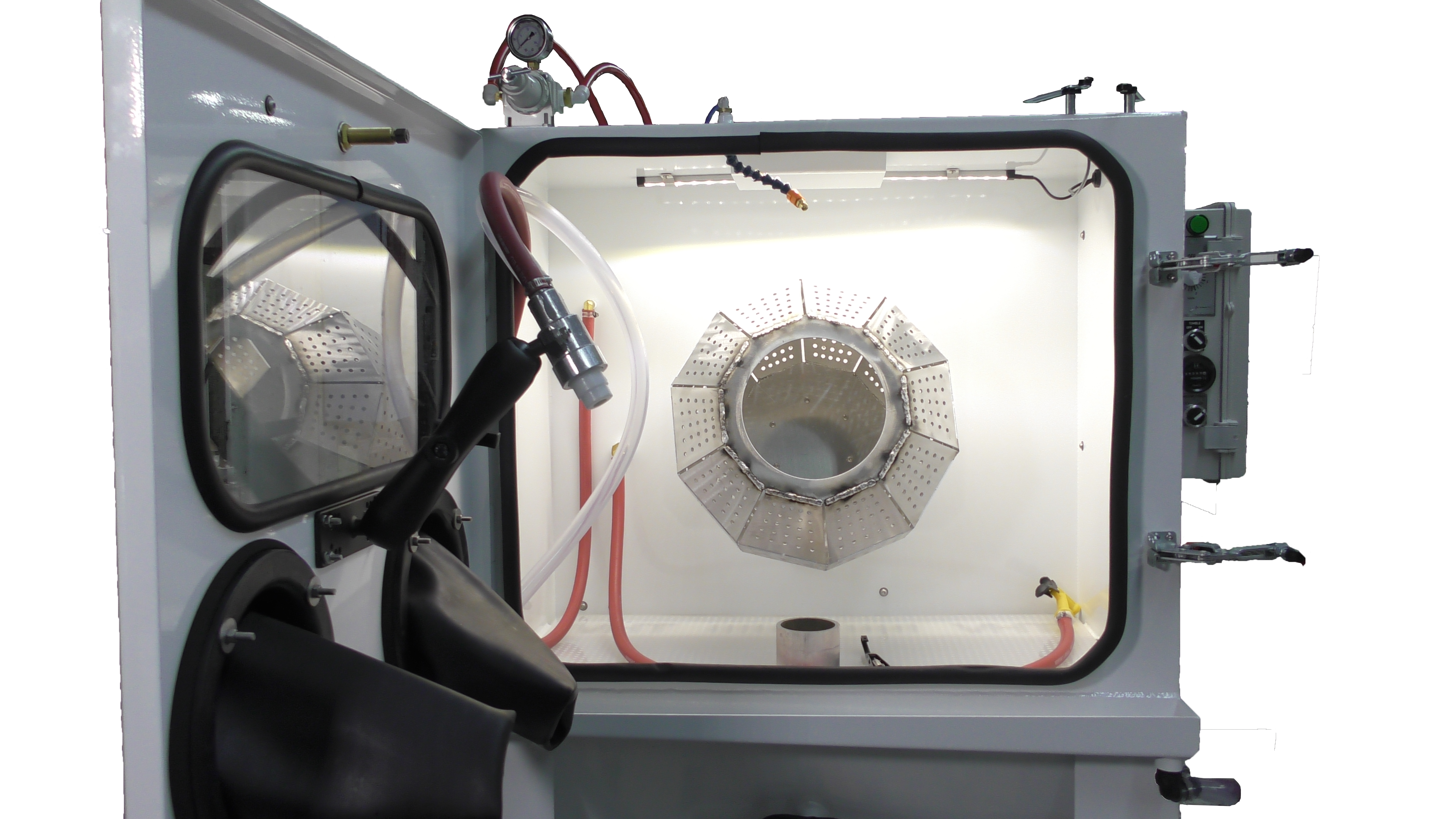

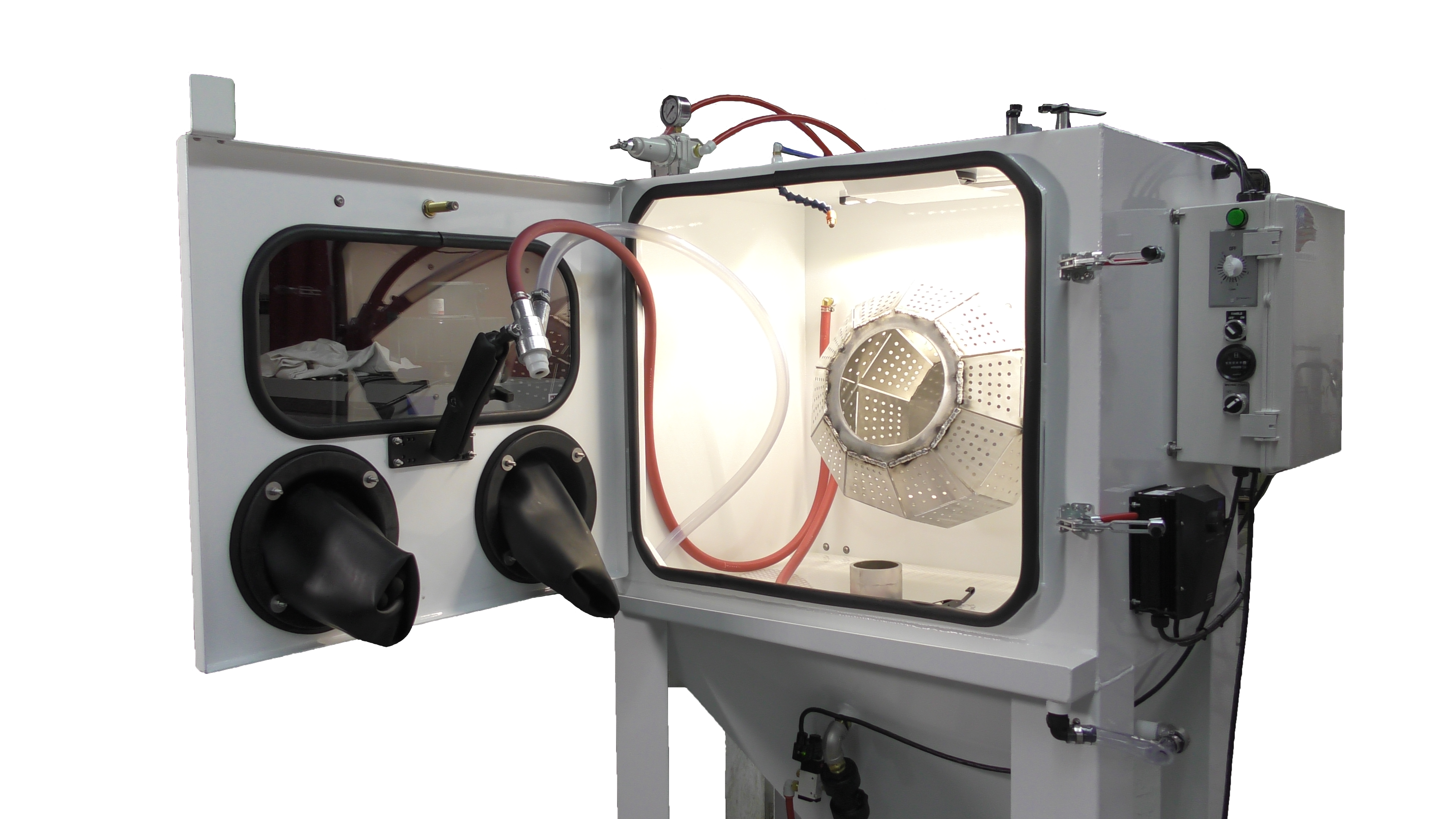

- 2 LED Light Bars for Better Visibility

- 1/2″ NPT Air Connection

- Front Load Door for Convenience

- Automated Tumble Basket

- Removable Tumble Basket for Manual Touch Up

- Basket Controlled with Timer

- Immersion Heater (+$800. Makes Machine 220V Single Phase)

- Small Enough to Fit Through Doors

- Comes With Casters for Ease of Mobility

- High Volume Pump

- Window Wiper for Better Visibility

- Fully Factory Tested and Assembled Before Shipping

| Internal Working Dimensions | 36″ W x 24″ D x 30″ H |

| Power | 110v Single Phase |

| Abrasive Amount | 35 LBS |

| Water Amount | 24 Gallons |

| Nozzle | Standard Rinse Nozzle |

| Pump | High Volume Pump |

| CFM | 20-30 CFM |

| PSI | 60-100 PSI |

| Assembly | No Assembly Required |

Optional Add-Ons

Blasting Mat

22″ Turntable

Rubber Lined Walls (Protects Powder Coating)

Immersion Heater

Closed Loop

- What’s the regular maintenance on vapor blasters as a whole?

- How often do I change media and water?

- Can I mix in something to stop freezing in the winter if I don’t have the unit in a place with heater?

- What abrasive can I run in the vapor hone?

- Does vapor honing take a lot of CFM?

- Really just changing the water and abrasive that’s it. Consumables will last much longer in the wet systems due to the cushioning effect.

- If you use it every other day I would change every month. If its occasional use you might go 2-3 months.

- One of the most frequent questions that I don’t have a good solution for other than draining the machine if you know it will be sitting for more than a week in the cold weather. I personally try to minimize mixing any thing other than water and abrasive because it can create bad finishes if it throws out the PH of the slurry.

- Any abrasive that you run in a dry blasting cabinet will run in a vapor honing machine.

- It depends on what you define as a lot any wet cabinet need 15-45 CFM to operate just depends on what machine model you choose.

To learn more about Vapor Honing, visit our YouTube channel and subscribe to see more.

Click below