- The Wet Blast Indexing Station is backed up by the industry’s best LIFETIME WARRANTY

- 100% built in the USA

- American tech support Monday-Friday

- This Wet Blast Indexing Station is an industrial machine built to last a lifetime

- Front loading work station

- Fully welded and built from 1/4″ 304 Stainless Steel ( Over 2,000lbs. of Stainless )

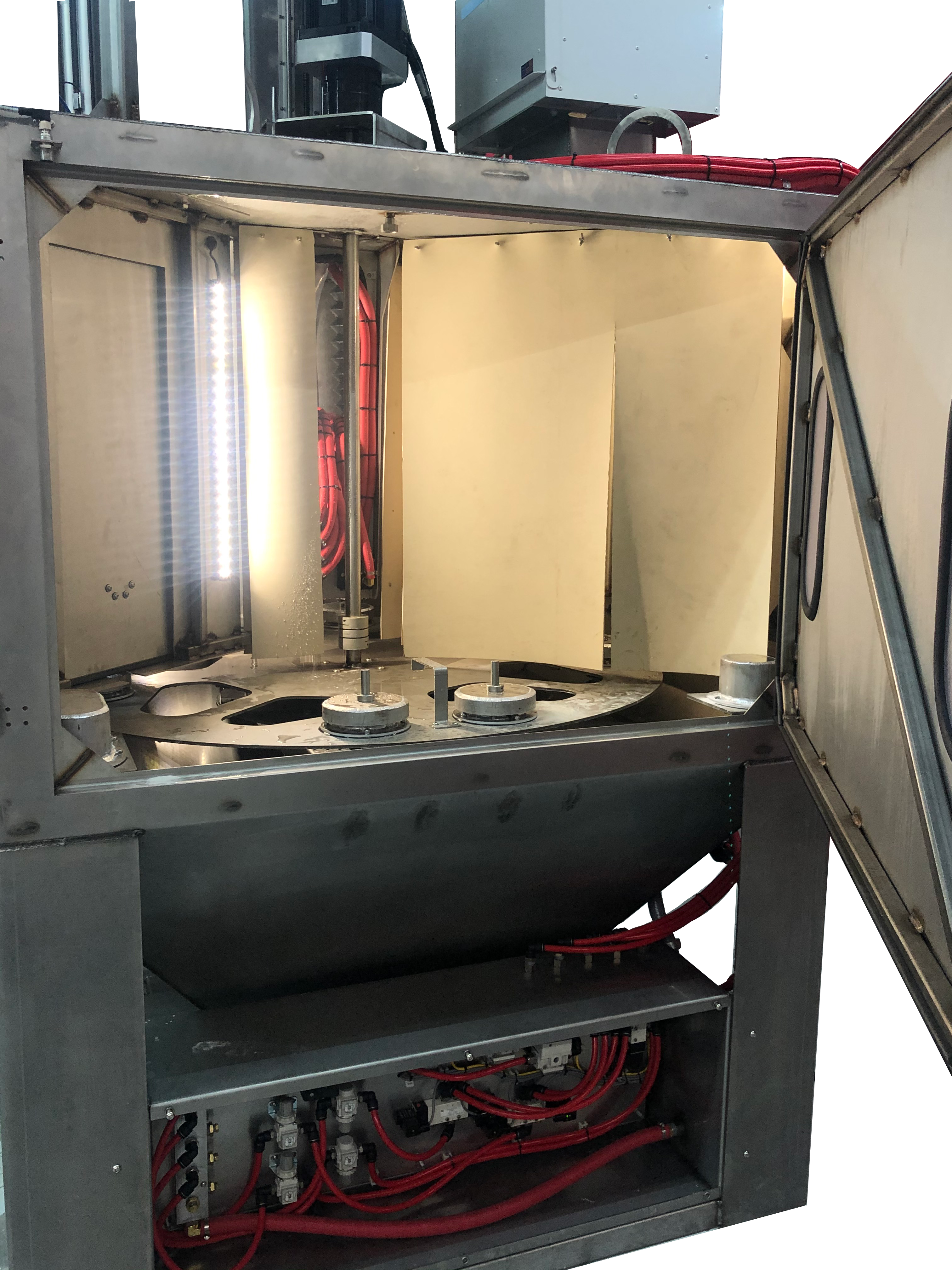

- LED lighting for better visibility

- Side door access the automatic drying chamber

- Pneumatic Panel for easy maintenance and troubleshooting

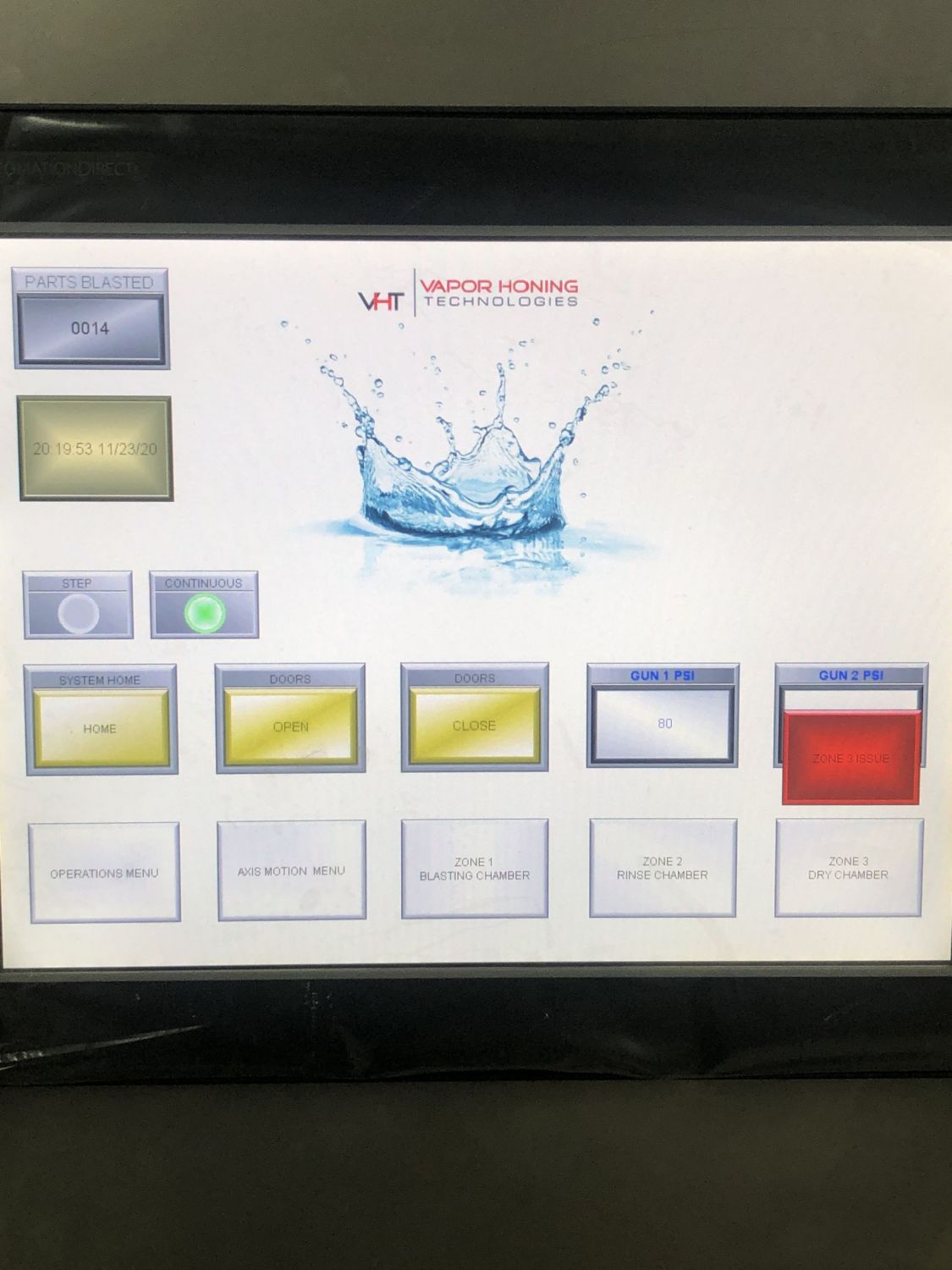

- Fully controlled pneumatics from the HMI Interface for greater process control

- Full built in industrial safety with workstation control pedestal

- Full HMI process control with the click of a button. The highest level of automation and programming all bundled into one machine

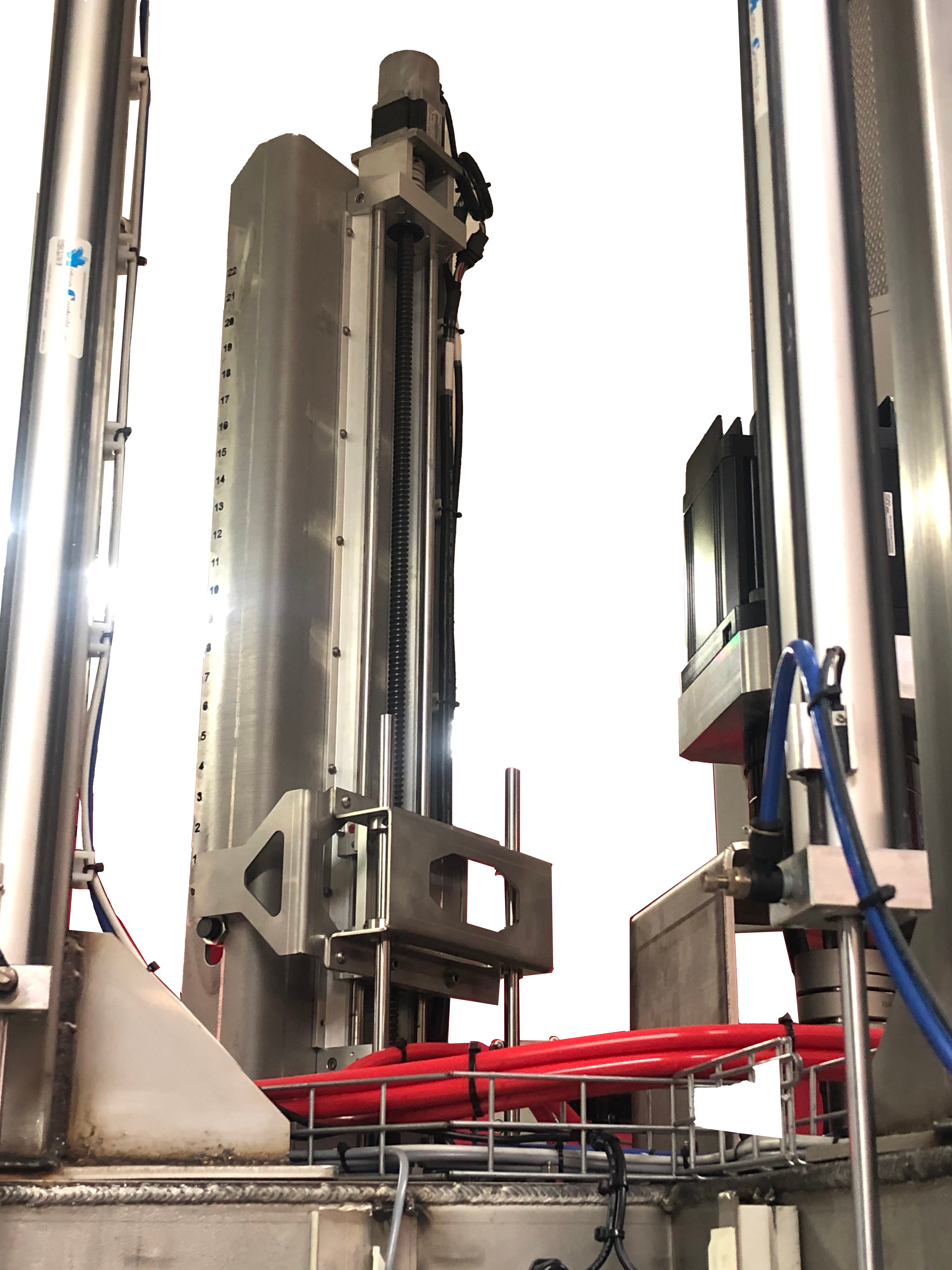

- Vertical motion driven by servos for the blasting gun chamber. Heavy duty linear motion to stand up to the toughest demands

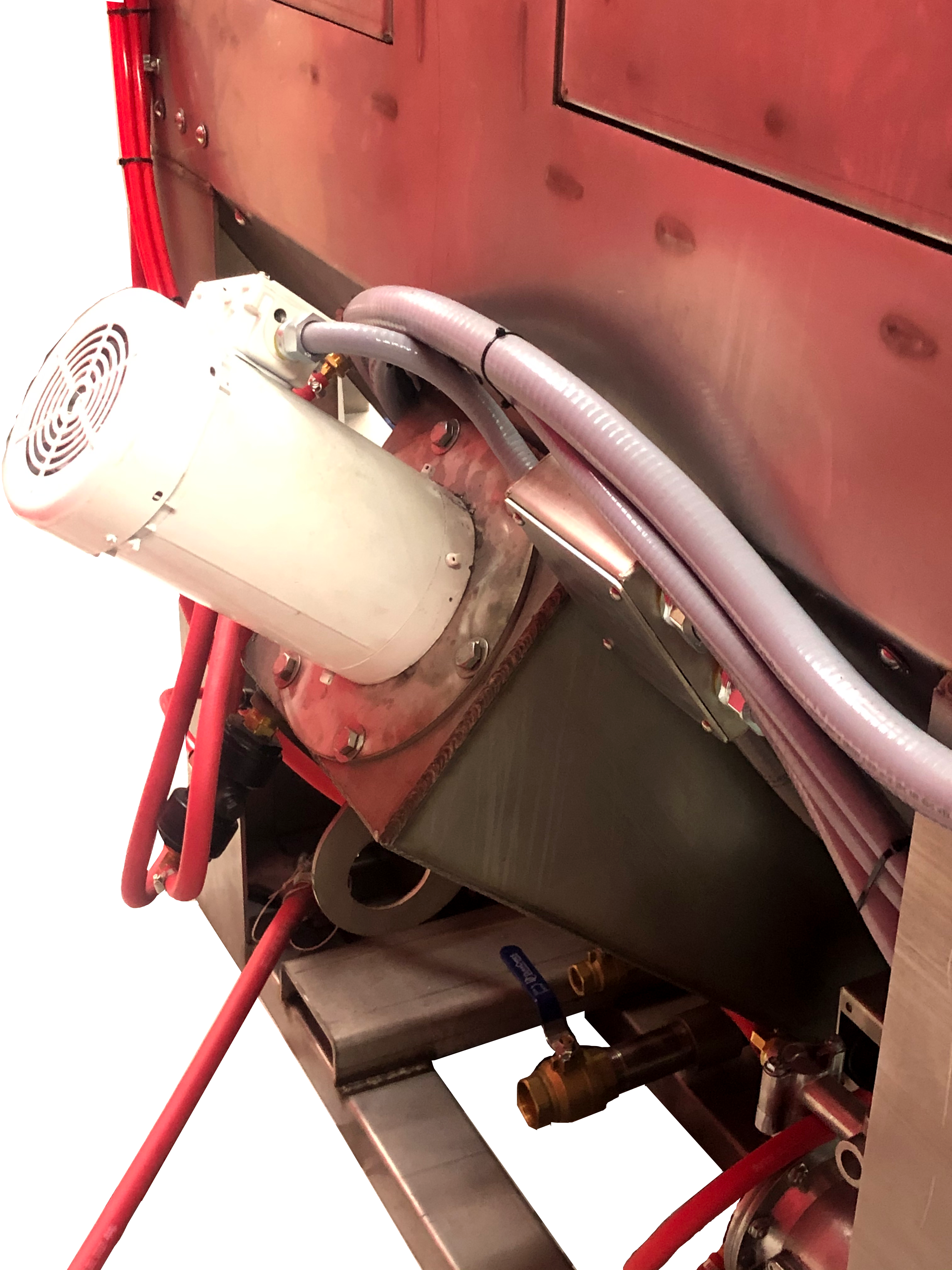

- Custom in house designed slurry pumping systems built specifically for the highest flow rates and duty cycle of this machine

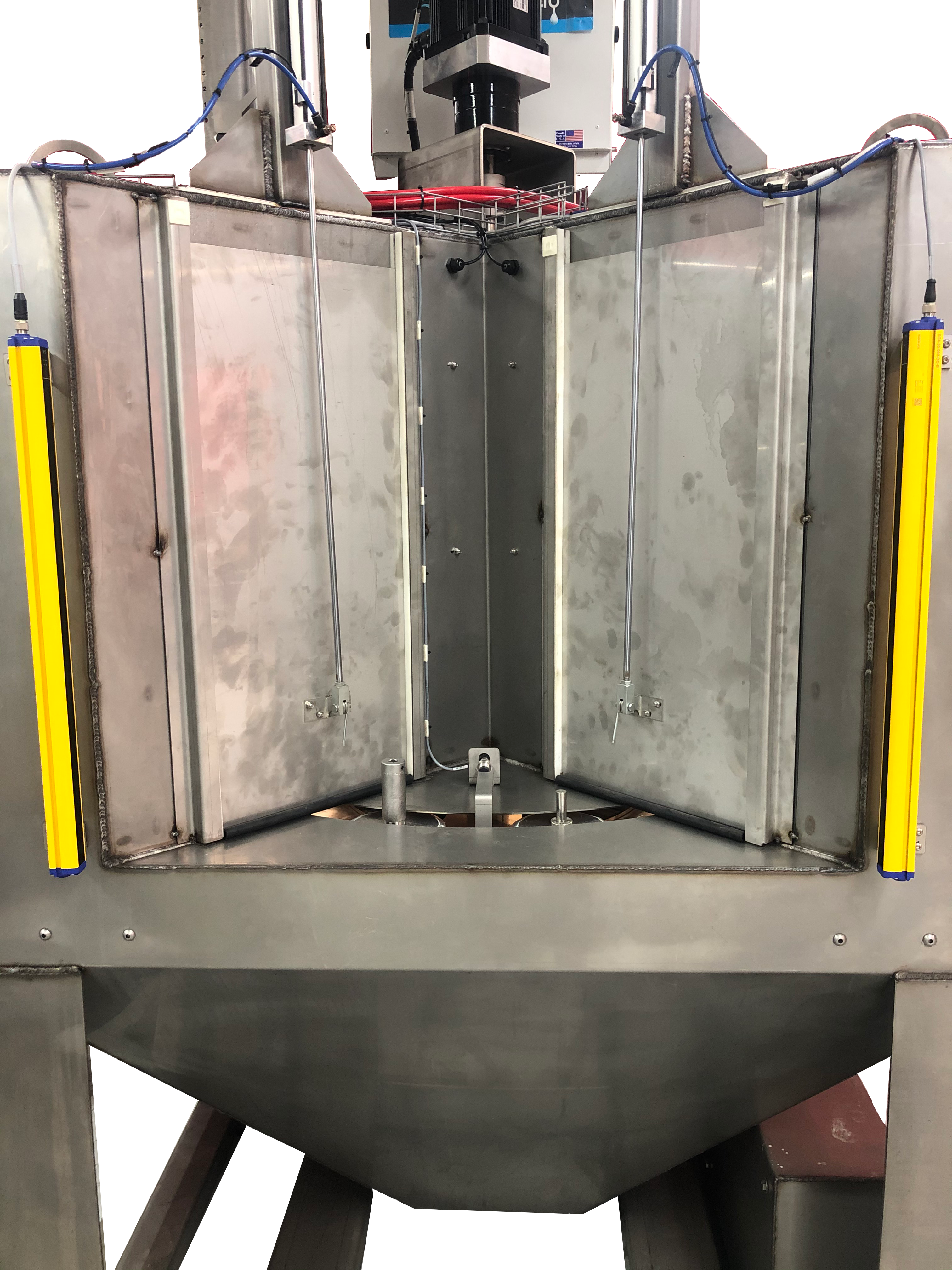

- Safety light curtains located at the front to protect users when machine is in motion

- Two spindles processing two parts simultaneously in each of the three work chambers

- Spindles are ready to accept custom fixtures made for your parts

- The automated indexing station is fully factory tested and assembled

- Control panel wiring built and designed in house to the highest standards

- Wet exhaust system fitted with optional HEPA filtration for the cleanest process on the market today

- All pneumatic cylinders, servos, and linear rails are located on the top of the machine for easy service and increased longevity

- 100 Gallon closed loop rinsing tank with filter paper roll for easy and efficient water filtration

- This tank feeds the continuous rinsing chamber rinsing two parts at a time

| Internal Work Dimensions | 60″ W x 60″ D x 48″ H |

| Power | 208V or 480V Three Phase |

| Motion System | Servo Driven Motion System |

| HMI Screen Size | Large HMI User Interface |

| Sedimentation Tank | Closed loop Rinsing Sedimentation Tank |

| Runoffs | Customer Supplied Parts For Runoffs |

| Abrasive Amount | 45lbs. |

| Water Amount | 75 Gallons |

| Pump | High Volume Slurry Pump |

| Pump Impeller | Industrial Polyurethane Pump Impeller |

| Gun Tips | Boron Carbide Blasting Gun Tips |

| Compressor Specs | 35HP or Larger |

| CFM | 150 CFM |

| PSI | 150 PSI Max Pressure |

| Assembly | No Assembly Required |

Optional Features

3K Sump heater

Abrasive density meter

- What’s the regular maintenance on vapor blasters as a whole?

- How often do I change media and water?

- Can I mix in something to stop freezing in the winter if I don’t have the unit in a place with heating?

- What abrasives can I run in the vapor hone?

- Does vapor honing take a lot of CFM?

- Really just changing the water and abrasive that’s it. Consumables will last much longer in the wet systems due to the cushioning effect.

- If you use it every other day I would change every month. If its occasional use you might go 2-3 months.

- One of the most frequent questions that I don’t have a good solution for other than draining the machine if you know it will be sitting for more than a week in the cold weather. I personally try to minimize mixing any thing other than water and abrasive because it can create bad finishes if it throws out the PH of the slurry.

- Any abrasive that you run in a dry blasting cabinet will run in a vapor hone machine.

- It depends on what you define as a lot any wet cabinet can need 15-45 CFM to operate just depends on what machine model you choose.

If you like to see other machines in action or our before and after results, please visit our YouTube channel and subscribe

Click Below