Vapor Honing Machines for Sale: Here’s Why You Should Buy One

Did you know that vapor honing is one of the best processes for cleaning and surface finishing in all industries? If you run a business where you clean and finish surfaces often—whether you’re a mechanical engineer or an engine builder—you have probably thought of whether you want to use a vapor honing machine.

If you’re thinking of buying one for your business, then you probably have many questions about vapor honing machines. You might be asking yourself:

“What is a vapor honing machine, and how does it work?”

“When it comes to vapor honing vs. sandblasting, which one is better?”

“What are the benefits of vapor honing technologies?”

Not knowing the answers to these questions can be frustrating. You might be frustrated because you want clear, fast answers that can help you decide if you want to make this purchase for your business.

That’s why we’ve put together this guide. By explaining what vapor blasting is and why you should buy one, you can decide if this technology is right for you. Finally, you can buy a vapor honing machine knowing that it’s best for your business. Read on to learn more.

What is Vapor Blasting?

To know if a vapor honing machine is right for your business, you first need to understand what vapor blasting is. This method—which is also known by names such as vapor honing, wet blasting, aqua blasting, dustless blasting, slurry blasting, and vapor honing—is a process that has two uses.

One of these uses is finishing a surface with the use of a mix of abrasive blast media and pressurized water. The other is to clean a surface by removing the contaminants on it.

When the mix of abrasive blast media and water is pressurized within a pressure pot before it hits the surface, this is called slurry blasting. This is because the mix of water and abrasive blast media is a slurry.

How Do Vapor Honing Machines Work?

When you’re doing vapor blasting outdoors, the abrasive in the machine comes out with the use of compressed air. Then, there’s a second hose that brings the water in through the blast nozzle (this is called a water injection), or that creates a circle of water that blocks some of the dust that’s made in the water blasting process (this is called a water ring or water halo).

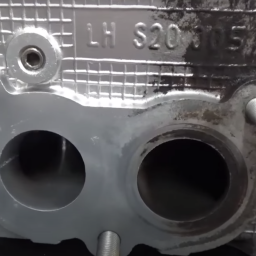

When you’re using a slurry blast cabinet, the process is a little different. When you use this method, you’re using a mix of abrasive media and water, which you mix together inside a hopper. Then, you propel this mix toward the object. This method is ideal for stripping or cleaning objects such as aluminum wheels or engine parts.

When it comes to the materials that are in the slurry mix, these are usually fine glass beads mixed with sodium bicarbonate or glass beads alone. If you’re doing vapor honing outdoors, the materials might be copper slag, Green Diamond nickel slag, or crushed glass.

What is Vapor Honing Used For?

The fact that vapor honing can be used for a variety of uses is one of the reasons why you should buy a vapor honing machine. Whether you work with cars and motorcycles, in industrial technology, engineering, or another industry, vapor honing has a variety of uses. Let’s review these now.

Industrial Applications

If you work on industrial applications, then vapor blasting is a great alternative to dry blasting. This is because, with dry blasting, there’s a risk of an explosion or fire occurring. When you’re doing dry sandblasting, and the abrasive hits the surface you’re blasting, this splits up the abrasive particles as well as dust.

This dust has a static electric charge. Because of this electric charge, you can end up creating dry sparks. If the material or air near where you’re sandblasting is at all flammable, you might end up causing an explosion or fire to happen.

With vapor blasting, you don’t have this risk. It’s far less likely. This is because you have cold sparks instead of dry sparks.

Motorcycles and Cars

If you work with motorcycle or car parts, then you should buy a vapor honing machine. You can use DIY vapor honing to clean contaminants, factory coatings, rust, and grease from motorcycle and auto parts. The process is fast for stripping and cleaning.

Additionally, because vapor blasting is gentler than dry blasting, you’re less likely to damage the parts. The finish will also be softer. Whether the surface is steel, chrome, or aluminum, the finish is soft like velvet or satin once you’ve used vapor blasting.

If you restore motorcycle engine parts, you can use a vapor honing machine for this activity, too.

Urban Settings and Outdoor Construction

If you work in construction, especially in urban settings, then using a vapor honing machine instead of a sandblasting machine is to your advantage. This is another reason to buy a vapor honing machine. The reason for this? There are many regulations now, especially in urban settings where there are many people in one area, on airborne dust.

With a vapor honing machine, you don’t have this problem, because the particles are wet instead of dry. The dust is more contained, which means you won’t be breaking any laws.

Sensitive Surfaces

If you work with sensitive surfaces, this is another reason why you should buy a vapor honing machine instead of a sandblasting one. Sandblasting, because it is a harsh process, can damage the sensitive surfaces you’re working with. On the other hand, vapor blasting has a lower PSI, which means that the process is more gentle.

If you clean up surfaces such as walls covered with graffiti, fire-damaged surfaces, wood that you’re restoring, or antique or historical objects you’re restoring, then a vapor honing machine gets the job done while maintaining the quality of the material.

Aerospace and Engineering

Vapor blasting is commonly used in the aerospace industry, specifically for peening and cleaning aerospace surfaces and parts. Additionally, it’s used to remove unwanted particles from engineering applications. These particles include general contaminants, paint, oxidation, and carbon deposits.

If you work in either of these industries, then you should definitely buy a vapor honing machine since it’s used in these important processes.

Blasting Soft Metal

Vapor blasting is also useful if you work with soft metals. If you use dry blasting, then this more aggressive method can end up warping the soft metal. However, with wet blasting, the liquid cools down the friction during the blasting, which means that it works better for blasting aluminum and stainless steel.

Vapor Blasting Versus Dry Blasting

Another reason to buy a vapor honing machine is that, in many cases, it’s a better choice for the process of cleaning and finishing surfaces than using a dry blasting machine. We’ll review the differences, which demonstrate why this is a better choice.

More Gentle

When you use a vapor honing machine, the blast that comes out of it is much more gentle than the blast that comes out of a dry blasting machine. This is because of the water in it. When the abrasive materials hit the surface you’re treating, the water softens the blow.

How does this work? The water is a dampener when you’re using a vapor honing machine. So, when you use it, the abrasive particles become enveloped by the water particles. This softens the entire mix. It’s also easy to clean since you can collect the water and abrasive mix after by putting it in a drain basin.

More Even

The other difference is that the spray that comes out of a vapor honing machine is more even than what comes out of a dry blasting machine. A dry blasting machine’s “stream” hits the surface at an angle, so if you want to use it on different areas, the result might be an unevenly treated surface.

With a vapor honing machine, on the other hand, the flow comes out more evenly. So if you want an evenly treated surface, you should use a vapor honing machine.

Additional Benefits of a Vapor Honing Machine

Now that we’ve discussed the uses for which a vapor honing machine is beneficial, and we’ve covered why it’s often a better choice than a dry blasting machine, we’ll review some of the additional benefits of using this type of machine. If any of these benefits sound like you would get something out of them, you should buy a vapor honing machine.

A Finer Finish

The most important benefit of using a vapor honing machine is that it gives you a finer finish. Whether you want a fine finish for aesthetic reasons or this fine finish is essential to the technology you’re applying the vapor honing machine technology to, you should use a vapor honing machine.

The reason for this is because the water washes away the abrasive materials right after they hit the surface. This means that they do not damage the surface; they only smooth it down properly. If you’re restoring antique furniture, vapor honing is a great choice for this reason.

Better for Preservation

Because the application of a vapor honing machine is more gentle, it makes it easier to preserve the surface you are treating. For example, if you’re cleaning an auto part or a part of your home, you don’t want it to be ruined by the treatment. You simply want to clean it well.

In this case, you should use a vapor honing machine. That way, you will keep the surface intact while cleaning it thoroughly.

More Efficient

A vapor honing machine is also incredibly efficient. You can blast, de-grease, and clean a surface all in one go. This is much faster than with dry blasting since there’s a lot of clean-up involved afterward. This is useful for DIY home construction projects.

More Abrasive Media Options

When you’re using a vapor honing machine, the water and abrasive mix makes it possible to use a variety of abrasive media options. You can use finer abrasive media, which isn’t possible when using a dry blasting machine.

Dust-Free

Because you’re using water with a vapor honing machine, you won’t have residual dust while using it. This means there will be less dust in the air, which makes getting the job done easier. Additionally, you won’t have a lot of leftover dust at the end to clean up with the wet blasting process.

Quieter Machine Operation

A vapor honing machine has a maximum sound when you’re running it of 70 to 75 decibels. So if you don’t want to damage your hearing or disturb a business or other people nearby, a vapor honing machine is the right choice.

Need More Information?

Do you need more information about vapor honing machines? Maybe you’re curious to learn about the vapor honing cabinet cost if you’re going to buy one. Maybe you want to learn about vapor honing services near you so you can use a vapor honing machine for a specific project.

Whatever information you need, we’re here to help. At Vapor Honing Technologies, we’re experts when it comes to vapor honing machines. We also sell equipment and offer services. To learn more about how we can help you, contact us here.