What Is Wet Blasting? Explained!

In short: Wet blasting is the use of a pressurized abrasive and water mixture to strip, clean, and finish parts. Other popular names for wet blasting include wet abrasive blasting, vapor blasting, vapor honing, dustless blasting, aqua blasting, or slurry blasting.

Wet blasting History:

In the early 1950s, Norman Ashworth created the first wet blasting machine. This machine was an answer to the banning of silica sandblasting. It was recently discovered that the sandblasting process caused silicosis, a non-curable type of pulmonary fibrosis. By adding liquid to the blasting process, the amount of airborne dust was vastly reduced, and wet blasting was born. Other benefits of wet blasting were quickly realized after its inception. The quality and consistency of the finishes provided by the new technology were unlike anything seen before. Due to vapor blasting’s benefits, it spread through industries and nations. This has allowed it to be, and to remain, one of the most prominent surface finishing technologies!

A Brief History of Vapor Honing Technologies:

From our humble beginnings in 2012, Vapor Honing Technologies has seen major success in all things vapor blasting. Our founder, Johnathan Wise, started the company out of his garage after struggling to find a sandblast option that fit his needs. Once the first machine was constructed, the service became just as popular as the motorcycle rebuild service he was offering. Through the success of the service, a need was realized. People needed a safer, cleaner, and better-performing alternative to sandblasting, but wet blasting was currently too expensive and unheard of.

The company that grew to fill this need strived to keep costs low and quality high. This meant offering an industry-leading lifetime warranty. In the end, we are still the same company, with the same values, same lifetime warranty, and the same customer-focused business style. We are Vapor Honing Technologies.

What Is Sandblasting:

Sandblasting, also known as abrasive blasting or dry blasting, is the operation of forcibly accelerating a stream of abrasive particles onto a surface intending to strip it. The process was invented around 1870 by Benjamin Chew Tilghman, a jack of all trades and an American hero. Since its creation, sandblasting has been used abundantly, but the health risks involved have dampened its usage. Specifically, with silica blasting, you are subject to non-curable diseases. For certain applications, sandblasting is still a good option, and its effectiveness as a surface finishing tool is undeniable.

What Is Wet Blasting:

Wet blasting, also known as vapor blasting and vapor honing, is a process similar to sandblasting. The major difference is vapor blasting includes a liquid in the blasting process. The addition of liquid cushions the abrasive as it hits the surface of your part and allows a smoother finish over sandblasting.

Notably, wet blasting is still just as effective as sandblasting. With extra cushioning, the abrasive is allowed to interact with the surface, rather than pound into it. An additional advantage of vapor blasting is the ability to clean and strip a part at the same time. The liquid in the cabinet acts as a solvent, washing away debris, while the blast media scrubs it away.

For an in-depth understanding of the pros and cons of vapor blasting, please check out our other blog.

What Can Wet Blasting Be Used For?

Vapor blasting is a typically used to finish a parts surface or prep it for a coating. Vapor blasting can be used on a plethora of materials, such as most metal, ceramic, plastic, rubber, and glass. There are, of course, more use cases. Wood has even been Vapor Honed before, but those listed are the most prominent.

For prepping a part, removing paint and rust can be an arduous task. With vapor blasting, it is an ease. With the correct abrasive, such as an aluminum oxide or silicon carbide, the sharp edges of the media will strip your part bear. These types of media also work well for heavily corroded, rust, and greasy parts.

For finishing a part, there is no better combination than glass bead and a Vapor Honing machine. The round abrasive creates a polished look, providing you with an OEM like finish. This will enhance your parts perceived value, making you more money.

After a part has been sandblasted, it must typically receive a coating because of its dull and unattractive finish. With vapor blasting, the easily achievable bright finishes can take the place of an expensive after coating.

What Abrasives Should I Use?

Abrasive, also known as blast media, is the substance used to remove unwanted substances off your part. Typically, abrasive is a very fine crushed mesh of the substance you choose. Sand, being the original blast media, is the best example of a blast abrasive. Others include glass bead, ceramic bead, aluminum oxide, and silicon carbide.

The blast medias with bead in their name are spherical, and create a bright satin finish on most metal parts. Aluminum oxide and silicon carbide are both angular and used for stripping, with silicon carbide being the more aggressive. To learn more about abrasive, and what kind is right for your use case, click here for more information.

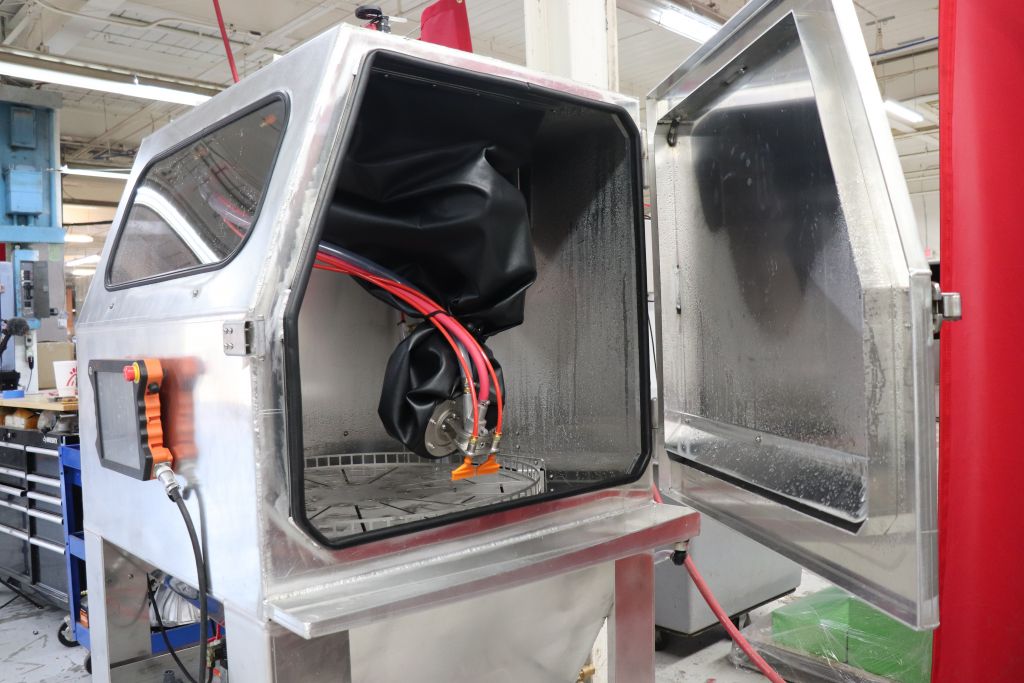

How Does A Wet Blast Cabinet Work?

Unlike sandblast cabinets which rely on gravity, siphoning, or pressure to transmit blast media, an aqua blast cabinet relies on a pump. In a Vapor Honing Machine, the pump is housed in the machine’s bottom in what is called the hopper. The pump serves two purposes: agitation and slurry supply. The agitation from the pump creates the perfect mixture of water and abrasive, also known as slurry. This is the mixture that is sent to the blast gun. When it reaches the gun, it is met with compressed air and sent towards the part. After the abrasive has hit the part, it may re-enter the hopper and continue the blasting cycle.

There are two systems Vapor Honing cabinets use when regarding rinse water, those being open and closed loop filtration. To differentiate these two systems and determine what is best for you, click here.

What Type of Machines Are Available?

Cabinet Style:

- A cabinet style vapor honing machine is the perfect solution for most items that require blasting. We offer a range of sizes to accommodate all parts, while fitting in your shop. Our cabinets workspaces range from 17″W x 13″D x 13″H to 60″W x 48″D x 38″H and everything in between. All of our cabinets offer the same premium finish and include our lifetime warranty. Our full list of blasting cabinets can be viewed here. To tailor a cabinet to your needs, we offer consulting and engineering to make sure we meet every specification.

Mobile Units:

- At Vapor Honing, we offer a machine made for those ready to tackle large projects. The Mobile Vapor Honing unit has an 18 gallon tank and requires 30 pounds of media per charge. This machine does not recycle media like a cabinet, but your work area is limitless.

Automated Machines:

- Automated machines are the solution for any industrial or high volume setting. These machines offer repeatability along with part processing ability, making them perfect for production. We currently offer an indexing station which can be adapted to your needs. For custom machine design, we would like to take on your project. Contact us here to create the machine your company deserves!

Robotic Machines:

- Robotic machines are the perfect balance between automated and manual cabinets. As a robot’s range of motion is not limited, these machines offer the same flexibility as a manual cabinet because all styles of parts can be blasted. Plus, robotic machines offer repeatability similar to an automated machine. To see more content on our robotic machine, click here.

If You Have Read This Far:

First, we really appreciate you! We hope this blog has been helpful in furthering your understanding of wet blasting. This blog was a general overview of the subject, so hopefully it was not too difficult to decipher. If any of the terms mentioned are unfamiliar to you, our excellent terminology page may be of help. To continue learning about vapor blasting and the benefits of Vapor Honing, check out our other blogs here. Thanks again for reading, and have a great day!